79

EN

Function over-

view

- Digital adjuster with power module (flow converter) for the wire-feed unit motor

- two-stage adjustment for permanent stabilisation of the motor:

a) Stabilisation of fast, dynamic changes, using a voltage/current regulator

b) Stabilisation of slow, dynamic changes, using a speed controller via the actual-

value pick-up

- Controls the wire-feed unit via PWM signal

- Full bridge for controlling the motor, changing the motor’s direction of rotation and

for controlled accelerating and decelerating

- The switched mode supply on the SR 41 is supplied with 24 V from outside the

power source, and ensures an independent supply for the PC board, and supply for

any connected peripheral devices with voltages of +15 V, -15 V and + 5 V .

- Controls the gas magnet valve, „blow-off“ signal

- Controls a push-pull system via the X12 plug

- Analyses the torch trigger signal

- Analyses the actual rotational speed value of the wire-feed unit motor,

- Analyses the robot sensor signals (e.g. wire end)

- 3 LocalNet interfaces for communicating between SR 41, power source, remote

control and options:

a) X2 for internal components (e.g.: control panel)

b) X6 for external components (e.g.: remote control)

c) X7 for the power source

Overvoltage protection (varistors) and overcurrent protection (PTC) on all LocalNet

interfaces, except X2

- Firmware update using BSL tool via programming connection X9

Technical Data

Supply voltage (from NT 24) + 24 V DC

Supply voltage (from NT 60) + 55 V DC

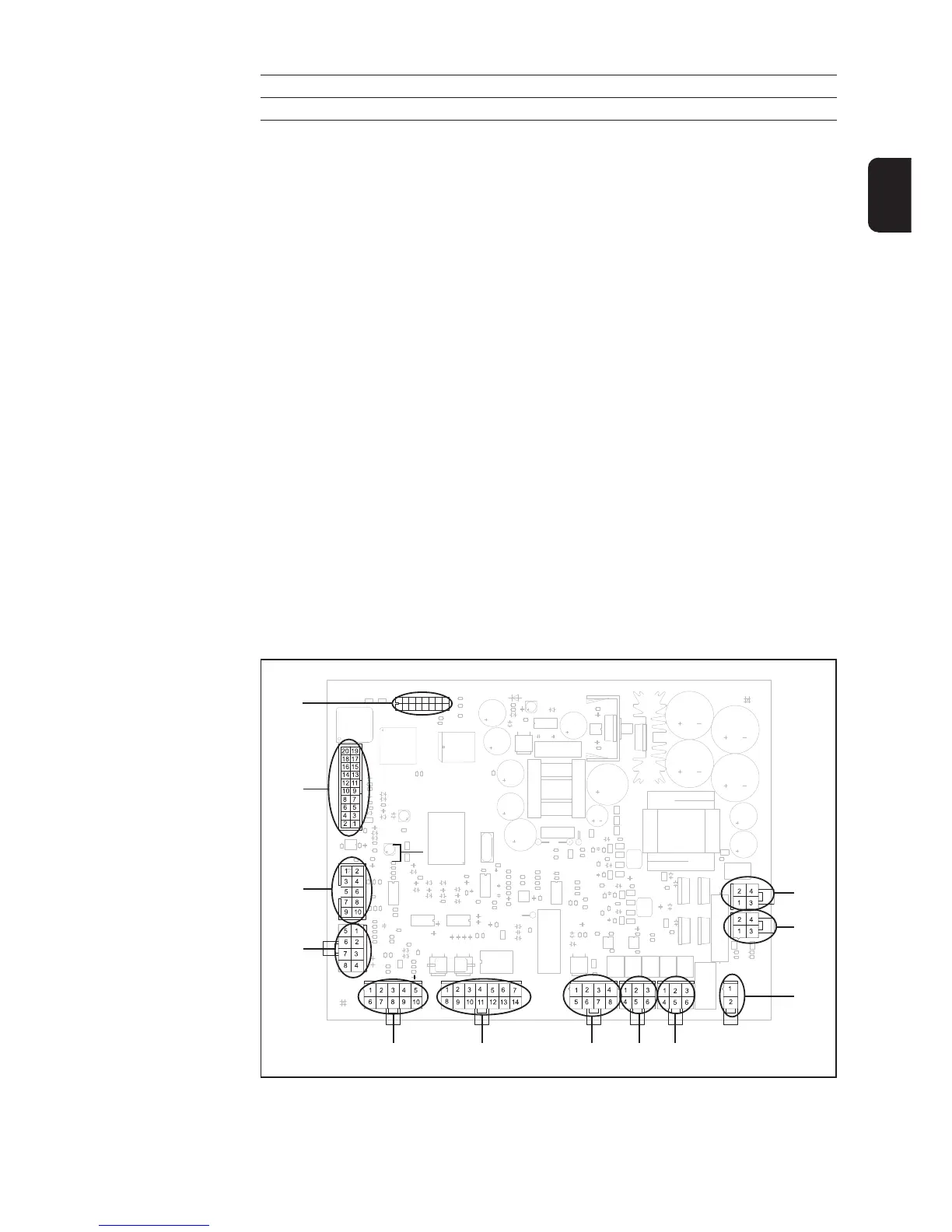

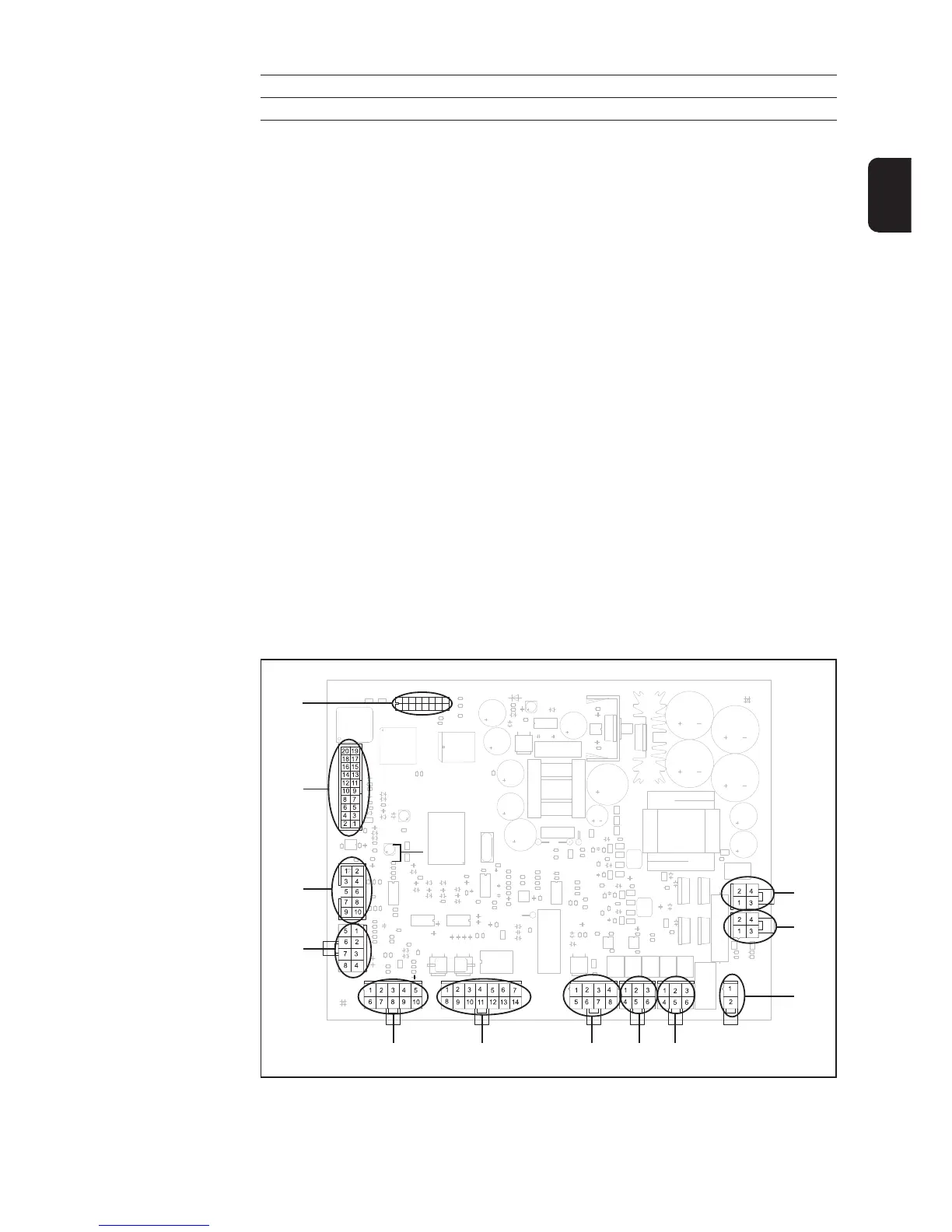

Plug layout

(X10)

(X4)(X3)

(X9)

(X6)

(X11)

(X1)

(X7)

(X8)

(X5)

(X2)

Fig. 55 Plug on SR 41 PC board

(X12)

Loading...

Loading...