GM Energy V2H Bundle Installation Manual 15

With two installers handling each, mount the Charger, the Hub, and the Inverter on their respective brackets.

Mount the Dark Start directly to the wall surface, ensuring that the integrated cable exits from the bottom of the installed

position.

Measure for, cut, route, and attach conduit between each component (adhering to NEC requirements). Depending on

your conduit and wire routing plan, conductors and cables might enter from the back, side, or bottom of the equipment. If

rear entry raceway holes will be used on the Charger, and you are installing the Charger outdoors, first apply a rainbow-

shaped bead of sealant on the back of the Charger around the knockout.

After you have installed all appropriate fittings and raceways (conduit or tubing) route and pull all wiring into the

Inverter, the Hub, and the Charger. Communication and control wires must be minimum #18 AWG; RS485 and CAN wires

must be twisted pairs.

Note: this guide provides examples of black/white twisted pairs—other colors are acceptable if and only if they meet the

minimum specifications.

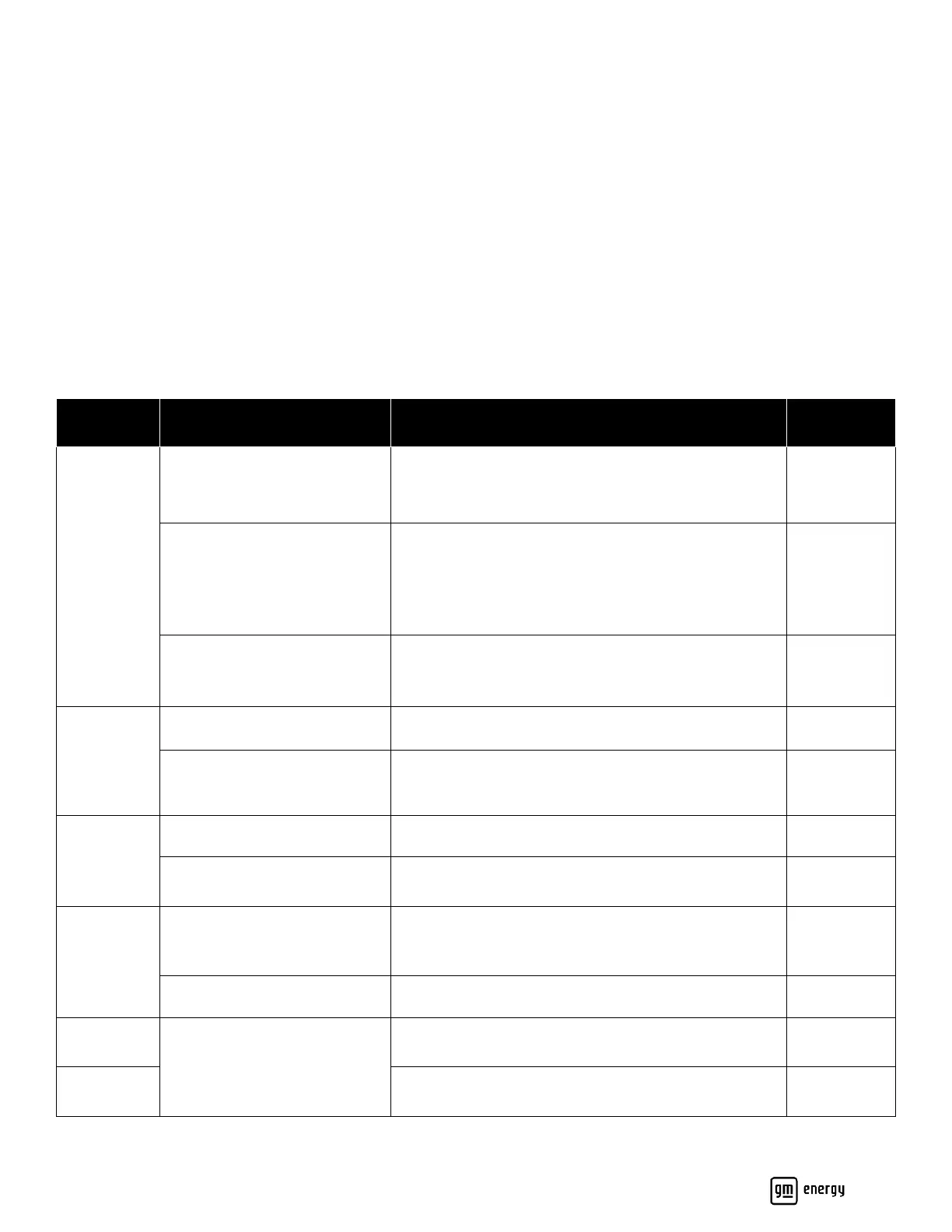

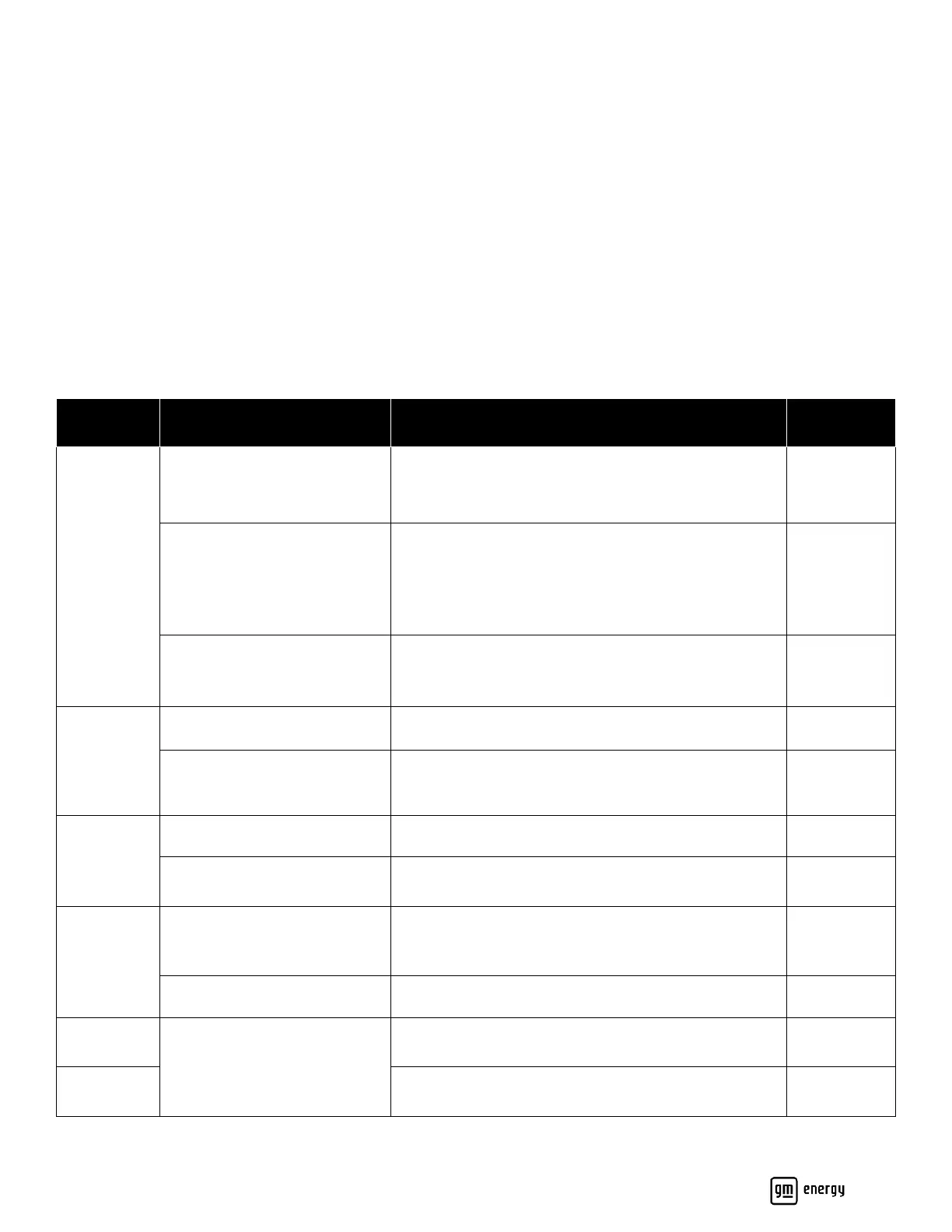

Lag screws must be minimum 1/4″ × 1 1/2″. Pilot holes shall be 60–75% of the fastener diameter (e.g. if 5/16″ lag screw

then 3/16″ pilot hole; if 1/4″ lag screw then 3/32″ pilot hole). Table 1 provides a summary of required mounting fasteners:

Sheetrock

(drywall) with

wood studs

Charger

(Holster requires 2 of same

fastener)

M8 × 60 mm (5/16″ × 2 3/8″) min. lags (qty. 2) into

framing member. Charger and holster may be center

mounted (one stud engaged) (Figure 5).

Hub and Inverter*

Blocking or plywood (minimum

5/8”) required

M6 × 76 mm (1/4″ × 3″) min. lags (Inverter min. qty. 4 at

16″ o.c.; Hub min. qty. 2 lags plus 2 anchors)

Hub may be center mounted (one stud engaged Figure

6); Inverter may NOT be center mounted.

M6 × 38 mm (1/4″ × 1 1/2″) min. lags (qty. 2) into

stud AND min. two #10 wall anchors at outer mounting

plate holes.

Charger

(Holster requires 2 of same

fastener)

M8 × 60 mm (5/16″ × 2 3/8″) min. lags (qty. 4).

Hub and Inverter*

Must have 5/8” (or thicker)

sheathing

M6 × 76 mm (1/4″ × 3″) min. lags (Inverter min. qty. 4;

Hub min. qty. 2 lags plus 2 anchors)

Sheathed

wall with

3/4″ plywood

Charger

(Holster requires 2 of same

fastener)

M8 × 60 mm (5/16″ × 2 3/8″) min. lags (qty. 4).

M6 × 76 mm (1/4″ × 3″) min. lags (Inverter min. qty. 4;

Hub min. qty. 2 lags plus 2 anchors)

Concrete,

hollow-block

CMU, or red

brick

Charger

(Holster requires 2 of same

fastener)

M8 × 60 mm (5/16″ × 2 3/8″) with anchors (qty. 4).

1/4″ × 2 3/4″ concrete screws (min. qty. 4)

3/16″ masonry

bit pilot hole

All surfaces

except concrete

1/4″ × 1 1/2″ concrete screws (qty. 2)

Loading...

Loading...