Published 08-25-09, Control # 077-04 2-85

RT9130E SERVICE MANUAL HYDRAULIC SYSTEM

Assembly

NOTE: Lubricate seals and rings with clean hydraulic oil.

NOTE: Make sure the gaps of the two wear rings are 180

degrees apart.

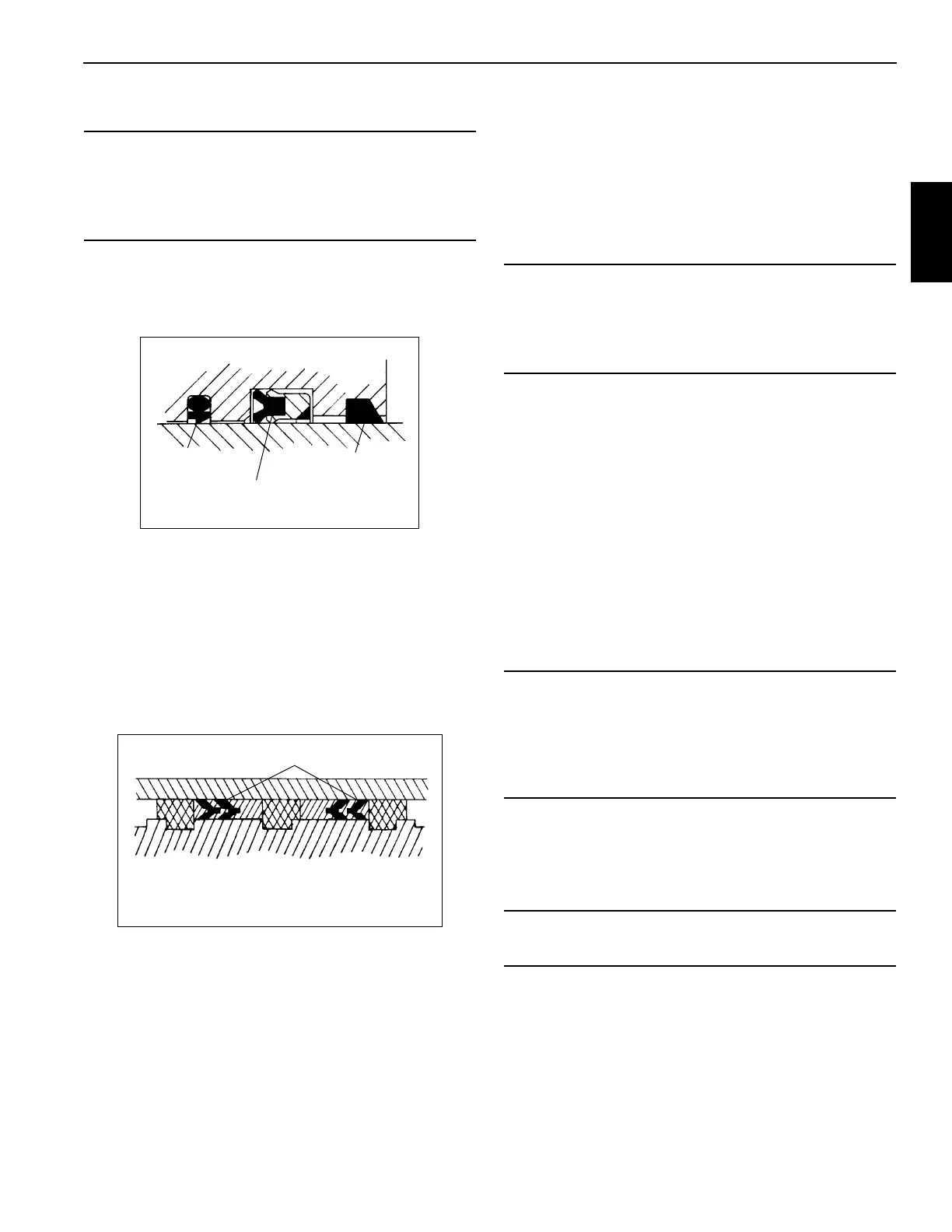

1. Install the replacement wear rings, buffer seal, rod seal

and wiper ring in the inside of the head (Figure 2-48).

Make sure the buffer seal’s step is away from the wear

rings. Make sure the deep Z rod seal rim groove is closer

to the wear rings.

2. Install the replacement o-ring and the backup ring on the

outside of the head.

3. Install the replacement o-ring and backup rings in the

inside of the piston.

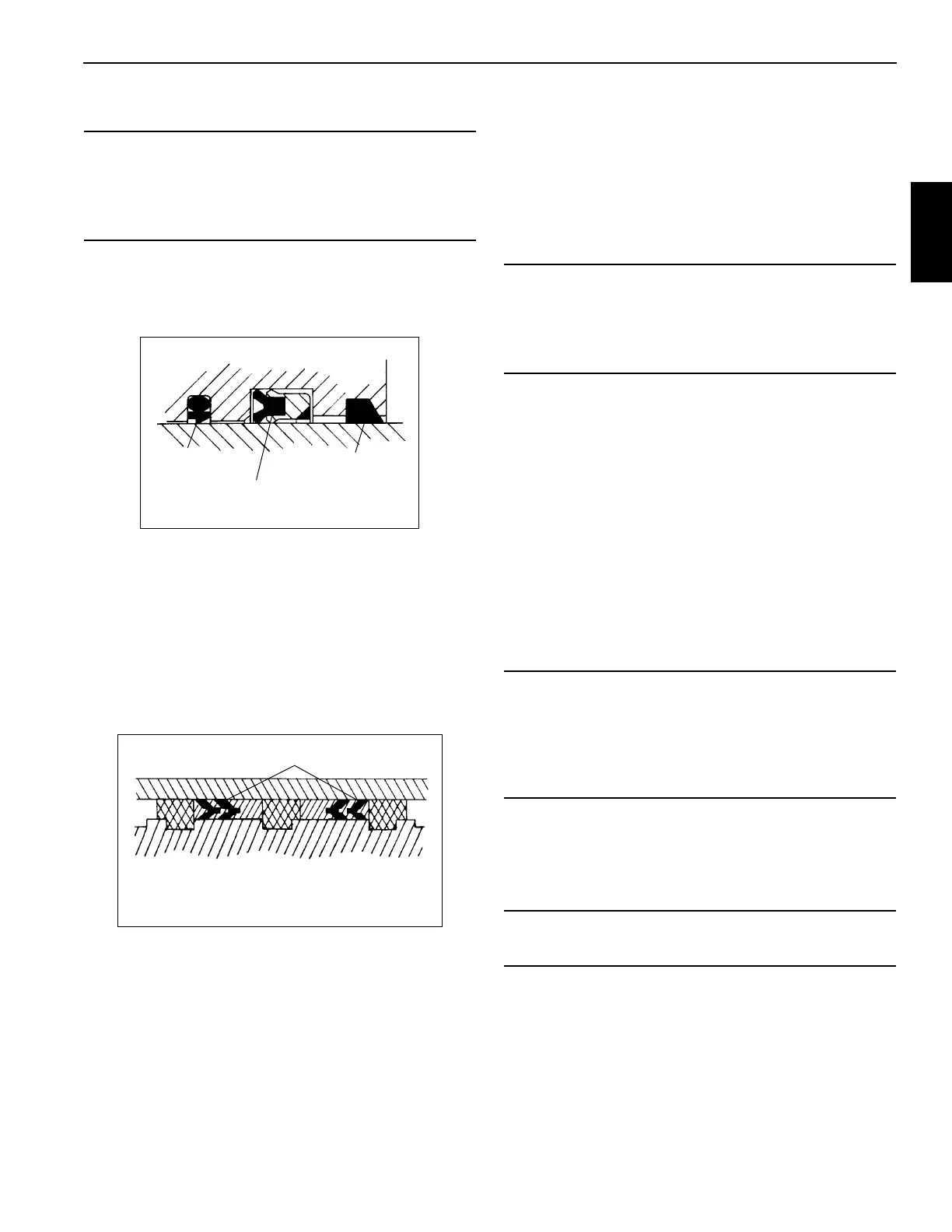

4. Install one replacement hydrolock seal on the outside of

the piston (Figure 2-49). Leave the other hydrolock seal

off for now so there is still access to the piston’s set

screw hole.

5. Lubricate the rod with clean hydraulic oil.

6. Slide the head, larger OD end first, onto the rod.

7. Slide the spacer onto the rod.

8. Screw the piston onto the rod until it can go no farther.

Hold the piston in place with the set screw.

9. Install the other replacement hydrolock seal on the

outside of the piston over the set screw. Make sure the

“vees” on the two hydrolock seals point at each other.

10. Lubricate all parts freely with clean hydraulic oil.

11. Remove the cover from the barrel. Insert the rod and

attached parts into the barrel with a slight twisting

motion.

12. Clean all oil from the threads of the head. Coat the

threads with an anti-seize compound (Never-Seez paste

lubricant or similar lubricant). Using a chain wrench,

screw the head into place on the barrel so its larger OD

end is flush with the end of the barrel.

13. Check the inside of the port block for any sharp edges or

burrs and remove as necessary with emery cloth.

14. Install new o-rings onto the check valve.

15. Lubricate the check valve and o-rings with clean

hydraulic oil.

NOTE: The check valve should turn by hand until

compression of the o-rings begins.

16. Carefully install the check valve into the port block until

fully seated.

17. Pressurize and cycle the cylinder with hydraulic oil

pressure. Test the cylinder at 3620 kPa (5250 psi).

Check for proper operation and any leakage. Make

repairs as needed.

CAUTION

When installing new seals and rings, avoid stretching

seals or scratching the grooved or gland surfaces. Make

sure parts are clean before and during assembly. Make

sure seals and rings are installed in the proper order.

Wiper Ring

Deep Z Rod Seal

Buffer Seal

FIGURE 2-48

Hydrolock Piston Seals

FIGURE 2-49

CAUTION

Exercise extreme care when handling the rod. Damage to

the rod surface may cause unnecessary maintenance

and expense. Also, take care to avoid damaging grooved

or gland surfaces or rings or seals during rod insertion.

CAUTION

Do not damage the o-rings during installation of the check

valve. If the check valve turns freely then gets hard to turn,

then easy to turn, remove the check valve and check the

o-rings. They have probably been damaged by a sharp

edge of a port.

CAUTION

Do not use air pressure to cycle or pressurize the cylinder.

Loading...

Loading...