Page 44

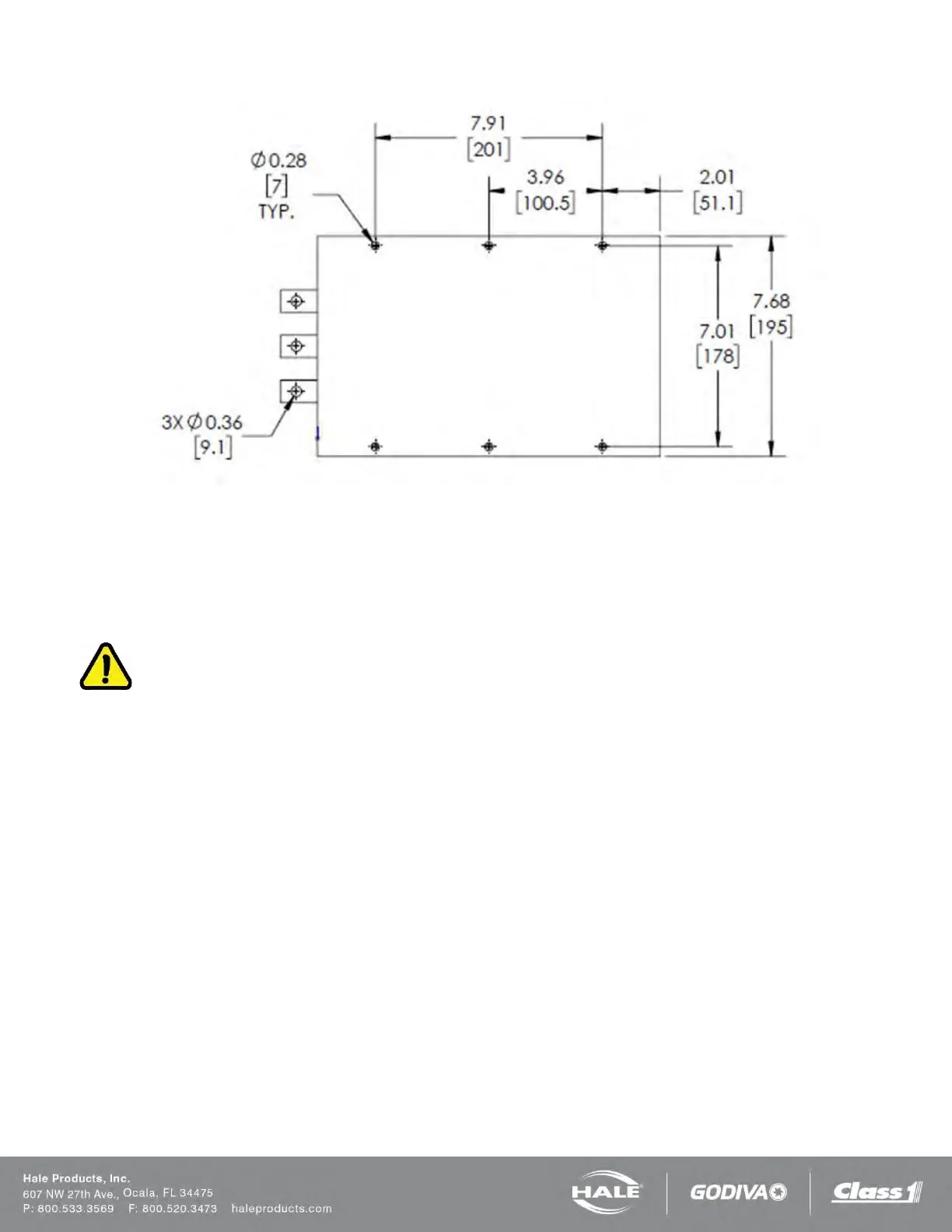

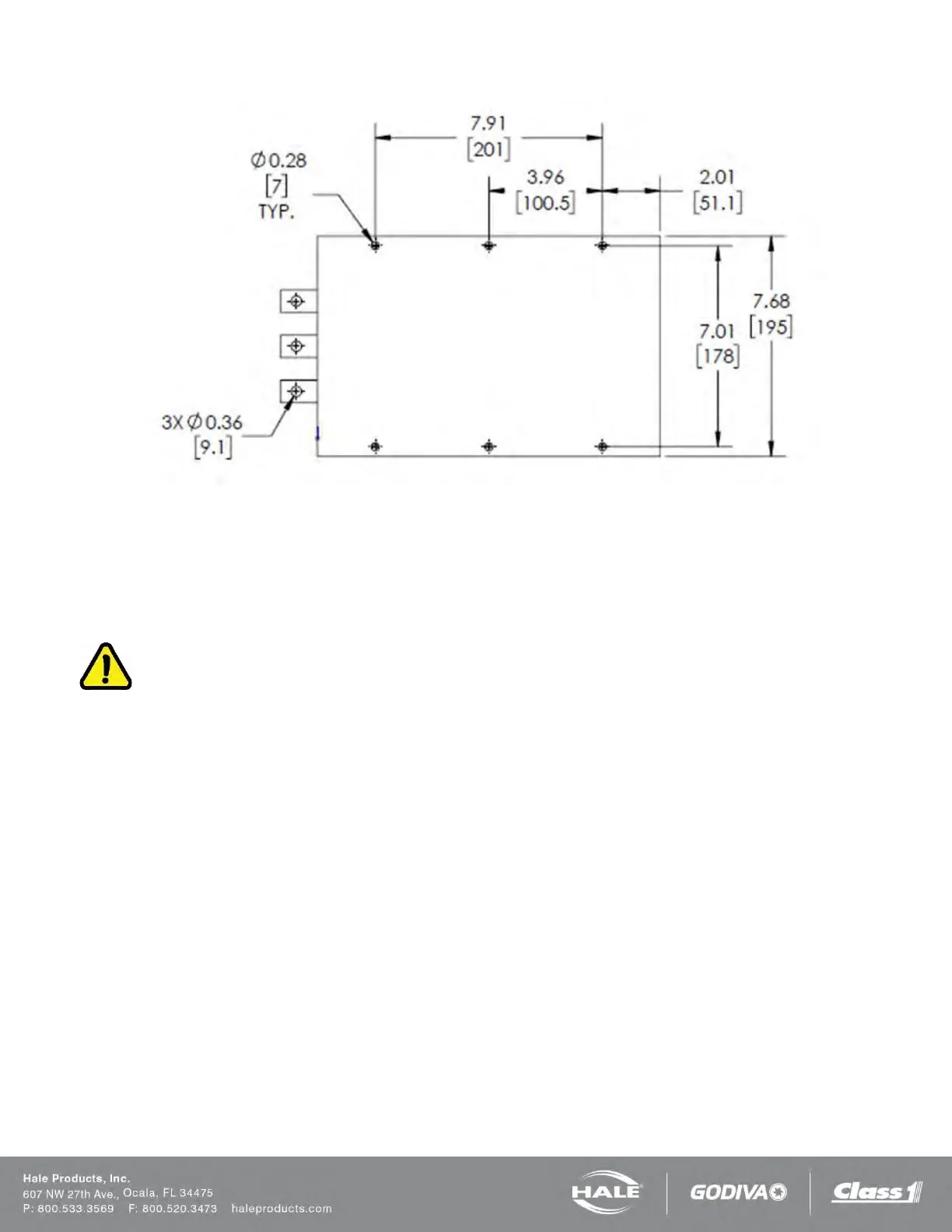

Figure 25: Converter Mounting Hole Locations – 6.5 12VDC (ONLY Required When Installed Remotely)

PLUMBING INSTALLATION

Hale SmartFOAM System plumbing diagram is located below. The diagram provides recommended guidelines for the instal-

lation of system components that handle water, foam concentrate and foam solution. The sequence in which the plumbing

installation is completed depends on your individual installation requirements.

IMPORTANT!

AFTER INSTALLATION, MAKE SURE ALL PIPES, HOSES AND TUBES ARE PROPERLY SUPPORTED USING THE

BEST INDUSTRY PRACTICES. USE A SUITABLE PIPE SEALING COMPOUND AT ALL JOINTS.

WATER AND FOAM SOLUTION PLUMBING

Use best industry practices when installing the water and foam solution piping runs. Use a suitable pipe sealing compound

at all joints.

CHECK VALVE MANIFOLD

Hale pre-made stainless steel foam manifolds are recommended. The manifolds are available in kits and eliminate the extra

labor and leaks from large pipe thread connections. The manifolds use 3” (76 mm) Victaulic connections and are available in

single or dual check valve configurations. Hale currently does not offer a dual injector port manifold. Figure 26 shows a typi-

cal check valve manifold installation.

Loading...

Loading...