Page 54

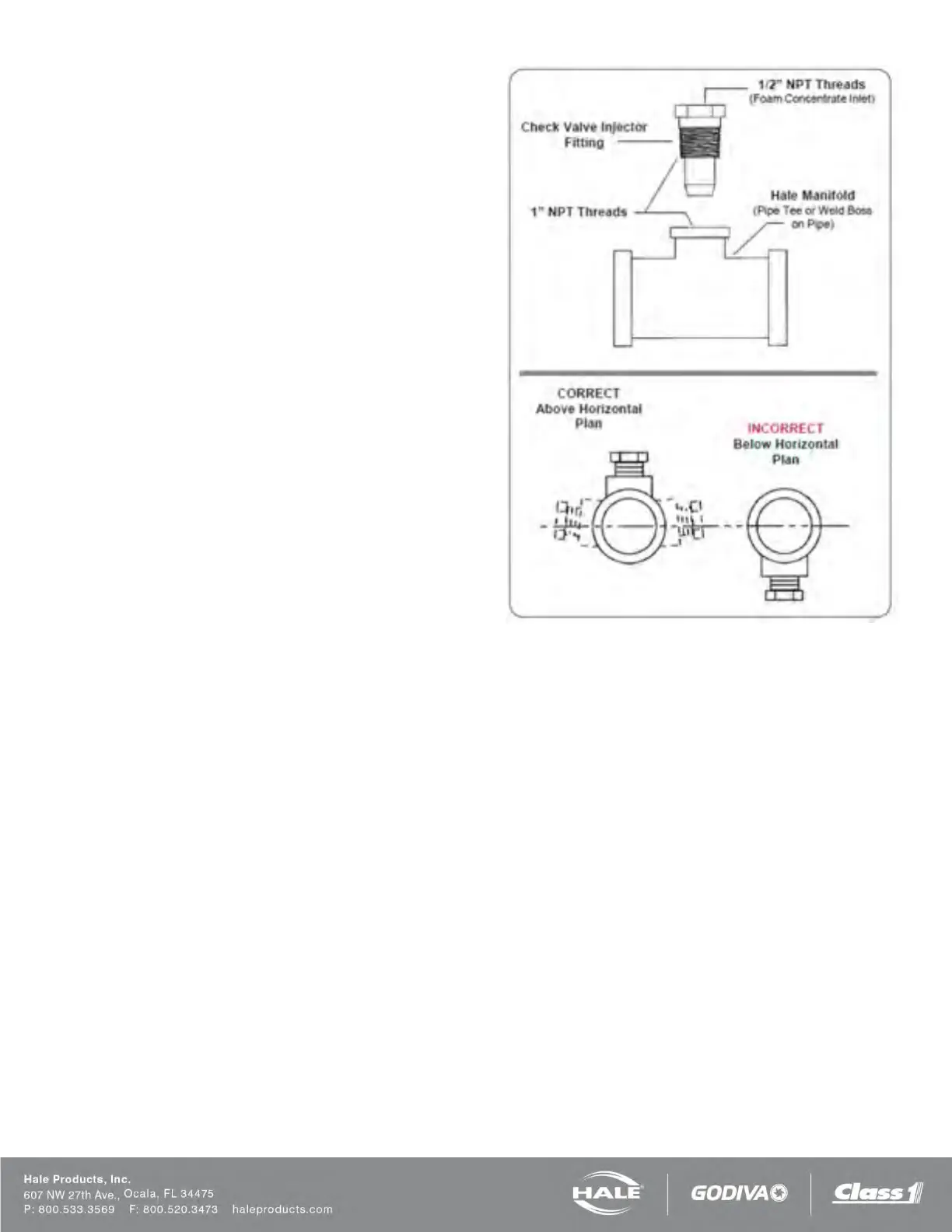

CHECK VALVE / INJECTOR FITTING

The Hale check valve/injector fitting, supplied with the

Hale SmartFOAM system, meets NFPA requirements for

a non-return device in the foam injection system. It pre-

vents back flow of water into the foam concentrate tank.

When properly installed the brass and stainless steel

construction check valve/injector fitting ensures foam

concentrate is injected into the center of the water flow

for better mixing.

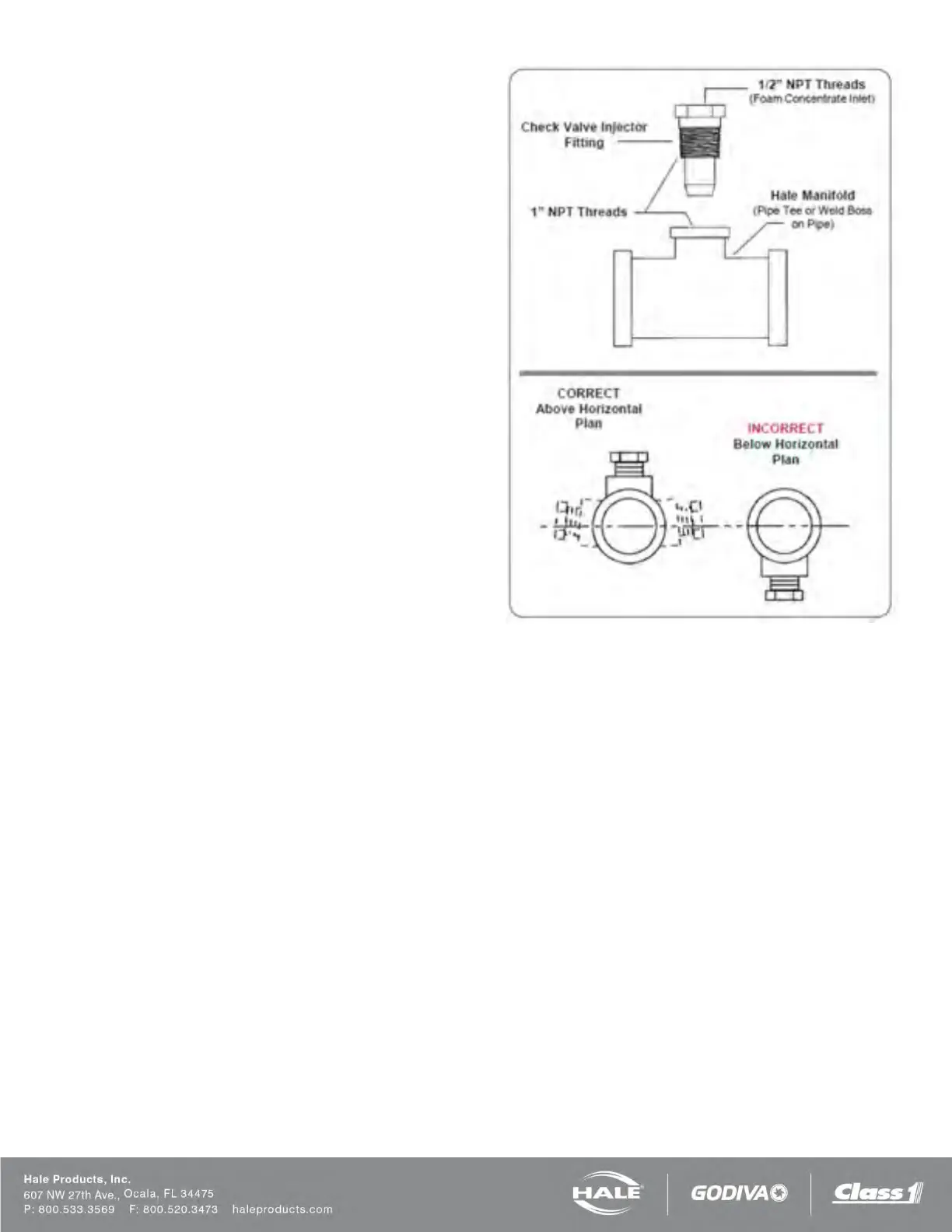

Note: Always position the check valve/ injector fitting at

a horizontal or higher angle to allow water to drain away

from the fitting (Figure 37). This avoids sediment de-

posits or the formation of an ice plug.

The check valve/injector fitting MUST be mounted in a

location that is common to all discharges which require

foam concentrate (Figure 38).

The Hale SmartFOAM system DOES NOT permit a sep-

arate injection point for each foam capable discharge.

However, when running Dual Pump (2) mode, the 2 in-

jection points must be installed on separate manifolds

since the pumps are designed to function independently.

The check valve/injector fitting has – 1” NPT (25.4 mm)

threads on the outside, to fit into the 1” NPT threaded

connection on the Hale mini manifold a pipe tee, or a 1”

NPT weld fitting installed in the discharge piping of the

fire pump (Figure 37).

The inlet connection of the check valve/ injector fitting

uses a 1/2-in NPT female thread.

Figure 37: Check Valve Injector Fitting Installation

Loading...

Loading...