Page 63

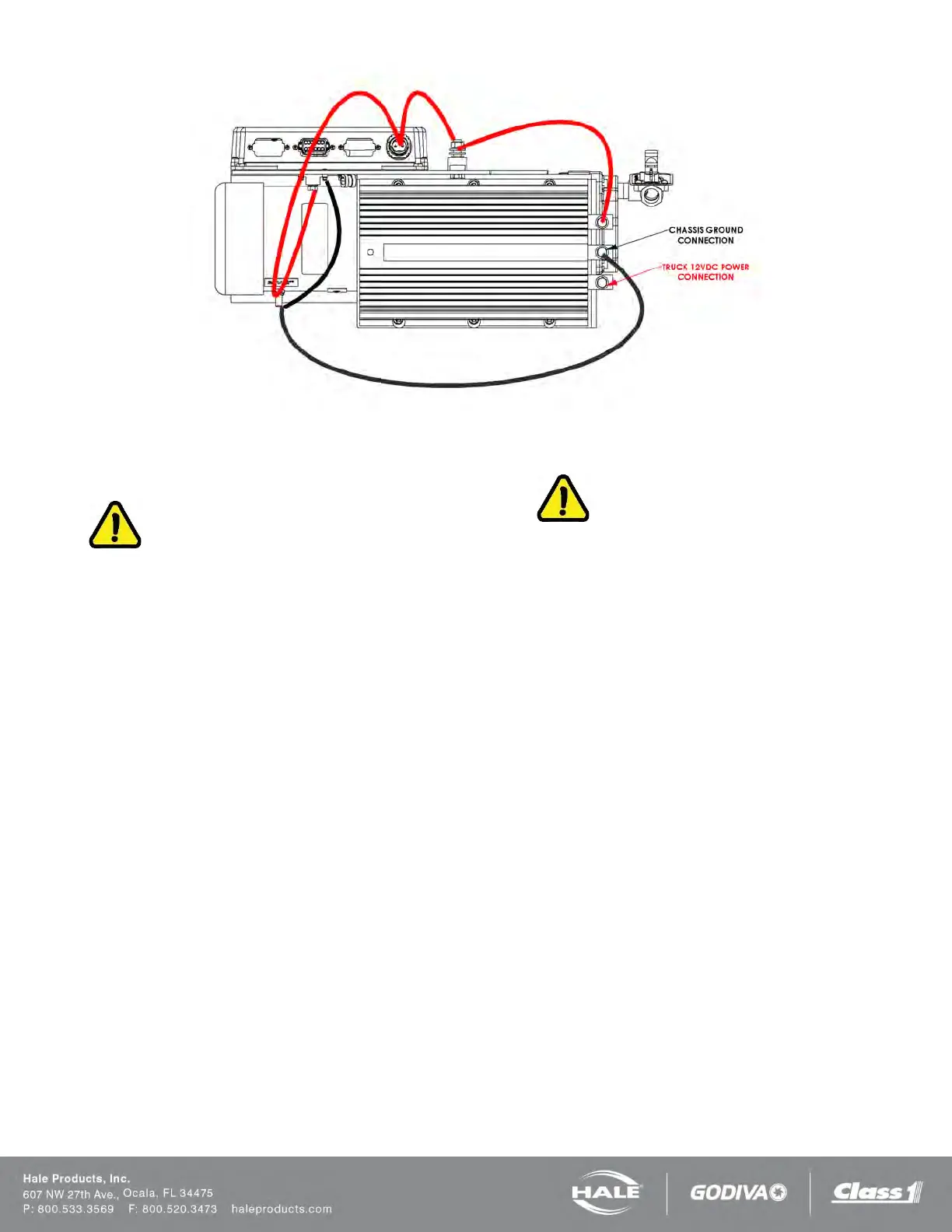

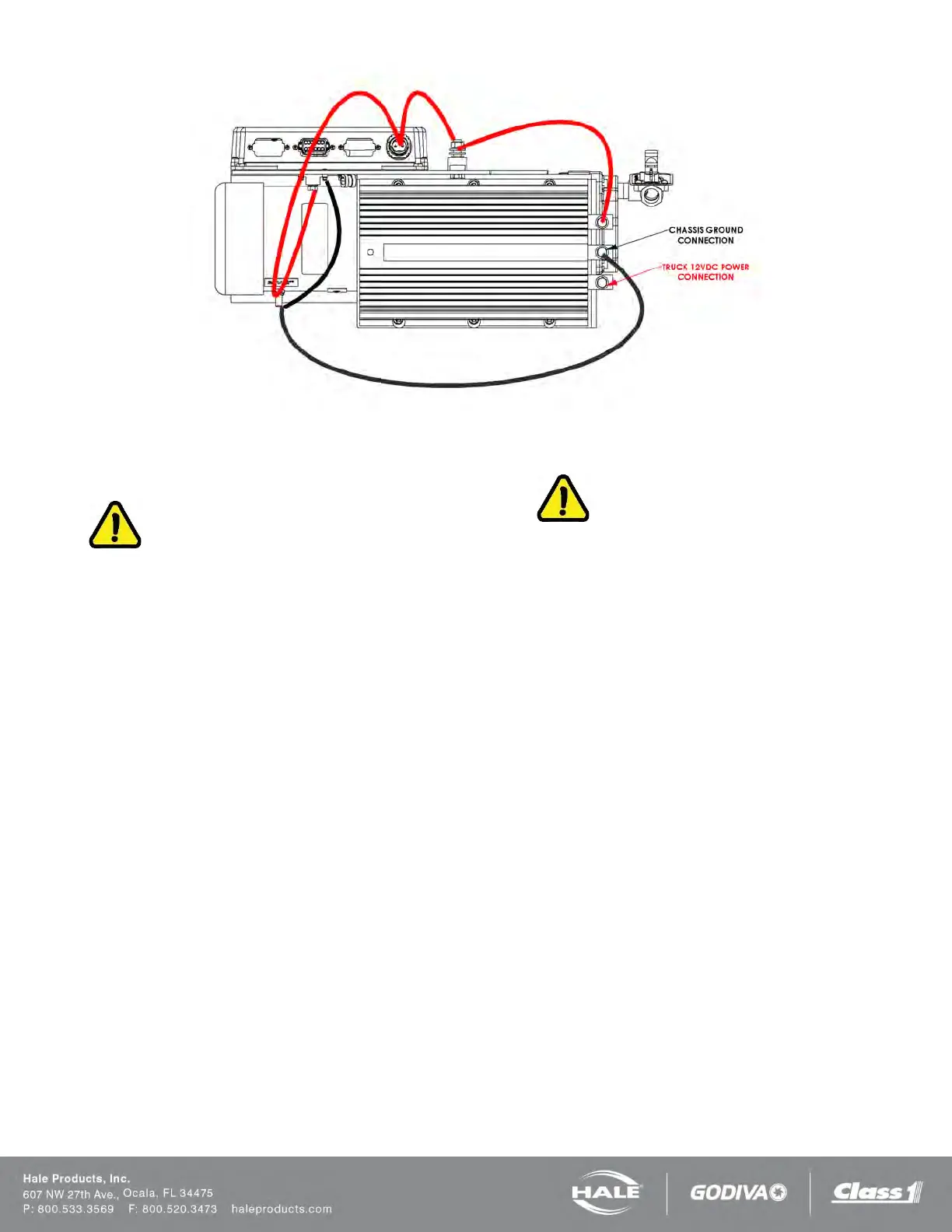

Figure 50: SmartFOAM Power and Ground Connections (6.5 12VDC)

MOTOR GROUND / PRIMARY POWER

CAUTION!

CONNECT THE PRIMARY POSITIVE LEAD FROM

THE TERMINAL BLOCK TO THE MASTER SWITCH

TERMINAL OR RELAY TERMINAL USING AWG TYPE

SGX (SAE J1127), CHEMICAL RESISTANT,

BATTERY

CABLE PER Table 6 OF THIS MANUAL AND PRO-

TECT WITH WIRE LOOM.

PREVENT CORROSION OF POWER AND GROUND

CONNECTIONS BY SEALING THESE

CONNECTIONS

WITH THE SILICONE SEALANT PROVIDED.

GROUND CONNECTION

Be sure the Hale SmartFOAM system is grounded to

the

chassis. Use a short length of wide flat ground strap at

least 1-1/4” (32 mm) wide and less than 18” (457 mm)

long to reduce the potential of RFI emitted by this con-

nection.

A stud is located on the mounting base to attach the

chassis ground strap to the Hale SmartFOAM system

(Figure 48, Figure 49, or Figure 50).

When making the ground strap connections make sure

lugs are soldered to the strap ends for trouble free con-

nections. Seal all connection against corrosion.

When the length of the ground strap exceeds 18” (457

mm) use a wider strap or a double thick strap.

CAUTION!

DO NOT CONNECT THE MAIN POWER LEAD TO

SMALL LEADS THAT ARE SUPPLYING SOME OTHER

DEVICE, SUCH AS A LIGHT BAR OR SIREN, AS THE

SMARTFOAM SYSTEMS HAVE A LARGE CURRENT

DRAW.

PRIMARY POWER SUPPLY CONNECTION

Ensure adequate switched electrical power from the bat-

tery positive (+) terminal to the “IN” connection stud on

the motor controller is provided (Table 6: Recom-

mended Primary Power Cable Sizes).

Use type SGX (SAE J1127) battery cable directly to the

battery, battery switch or solenoid. DO NOT

connect

power to the same connection as the pump primer.

When connecting the 12 V 6.5 system with the converter

located remote, wire the converter input and converter out-

put using Table 6: Recommended Primary Power Ca-

ble Sizes.

RFI / EMI

Proper installation of system components and cables

along with proper grounding will limit radio interference

caused by the Hale SmartFOAM system. Additionally,

make sure radio cables and hardware are not located in

the immediate area where Hale SmartFOAM equipment

is mounted.

Making round coils of extra control and flow sensor ca-

bles in the pump compartment can act as an antenna.

While the control and flow sensor cables cannot be

shortened, various lengths of cable are available to mini-

mize the “extra” cable in the truck.

Loading...

Loading...