Page 41

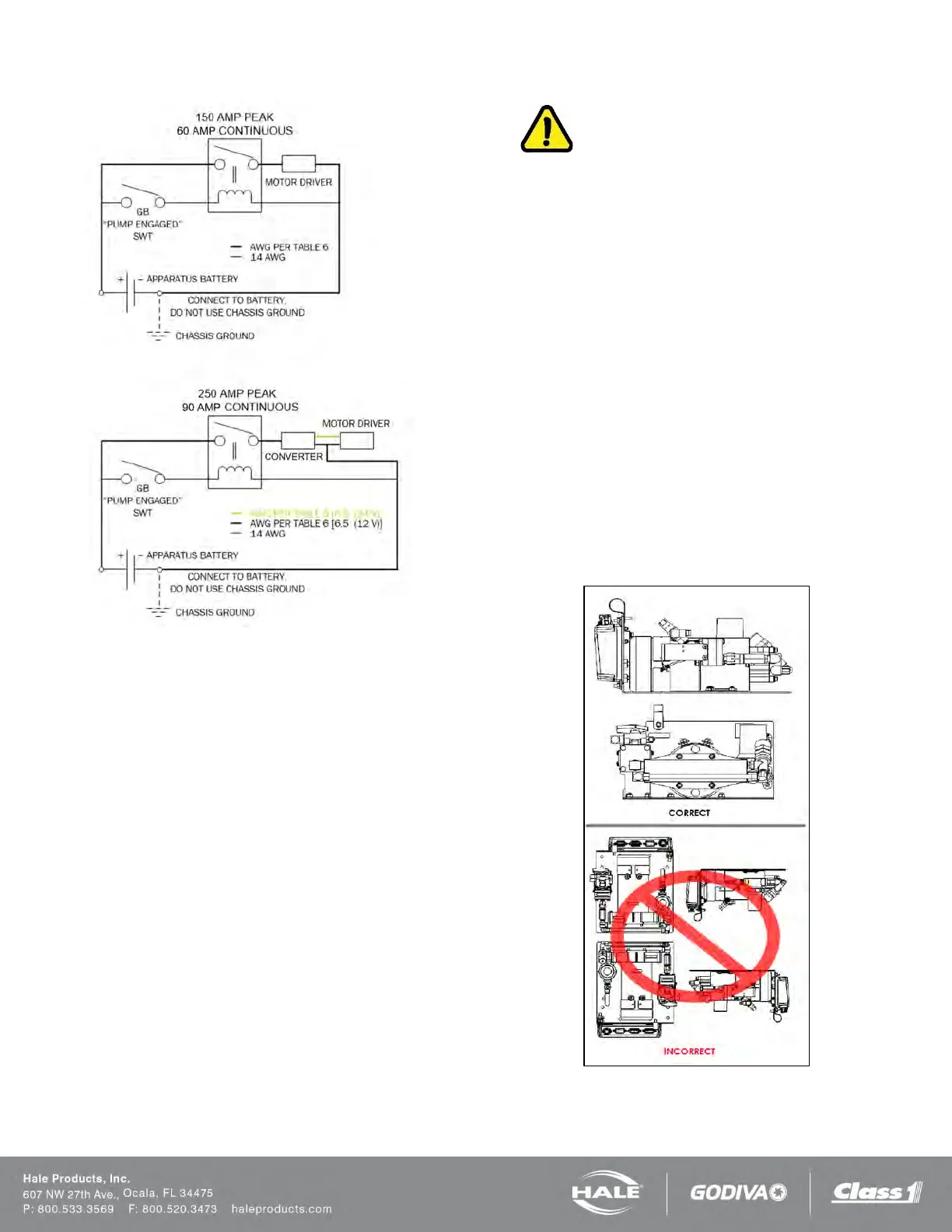

Figure 20: Recommended Relay Wiring Schematic

TOP = All Except 6.5 (12VDC) System,

BOTTOM = 6.5 (12VDC) System Only

When planning cable runs make sure the primary wires

are routed by the shortest most direct route. Use Table 6,

24V max lengths between a remoted converter and the

pump/motor.

A braided flat ground strap connected to the apparatus

chassis is recommended for the ground connection.

This limits the RFI/EMI interference encountered with ra-

dios, computers or other sensitive electronic equipment.

The ground strap should be a minimum of 1-1/4-in

(32 mm) wide and no longer than 18-in (457 mm). It must

have soldered flat lug ends with 3/8-in (10 mm) diameter

holes. If the ground strap length exceeds 18-in (457 mm),

a wider ground strap should be used or use a double thick-

ness of 1-1/4-in (32 mm) wide ground strap. The ground

strap must be connected to the chassis. Use minimum

5/16-in (8 mm) diameter bolt or mounting to secure the

strap.

Power and ground must also be provided for the display

unit using the 2 pin Packard connector. The power must

be a minimum 5 amp dedicated and fused circuit. The

ground must be connected to the chassis ground stud and

protected from corrosion. Make sure the ground is at-

tached directly to the chassis frame and not to the appa-

ratus body work.

IMPORTANT!

BEFORE MAKING GROUND CONNECTIONS REMOVE

ALL PAINT, GREASE AND COATINGS FROM THE CON-

NECTION AREA. AFTER MAKING CONNECTION, SEAL

AGAINST CORROSION. WHEN A FLAT GROUND STRAP

IS NOT AVAILABLE USE A BATTERY CABLE ONE SIZE

LARGER THAN THE POWER CABLE USED.

FOAM CONCENTRATE TANK

A foam concentrate tank must be supplied to suit the capac-

ity required for the apparatus application. The tank must

meet NFPA minimum standards for its design capacity, in-

cluding:

❑ Filler size

❑ Vapor pressure venting

❑ Baffling

❑ Drain facilities

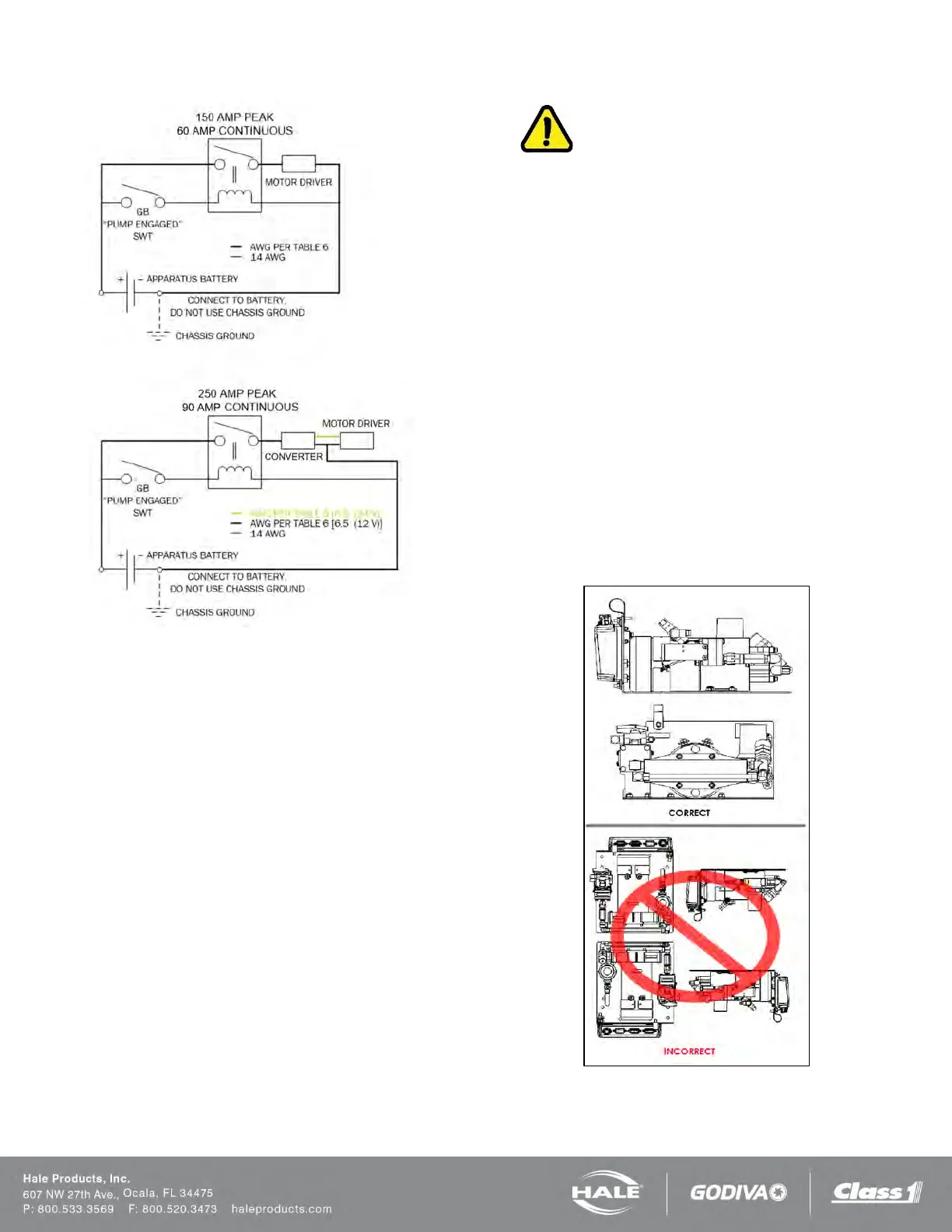

FOAM PUMP MOUNTING

Position the foam pump and motor assembly in the desired

location on the apparatus. When installing the foam pump

and motor assembly, the assembly should be kept in a

HORIZONTAL position with the base plate on the bottom.

(See Figure 21 or Figure 22).

Figure 21: SmartFOAM Piston Pump Installation

Loading...

Loading...