Page 83

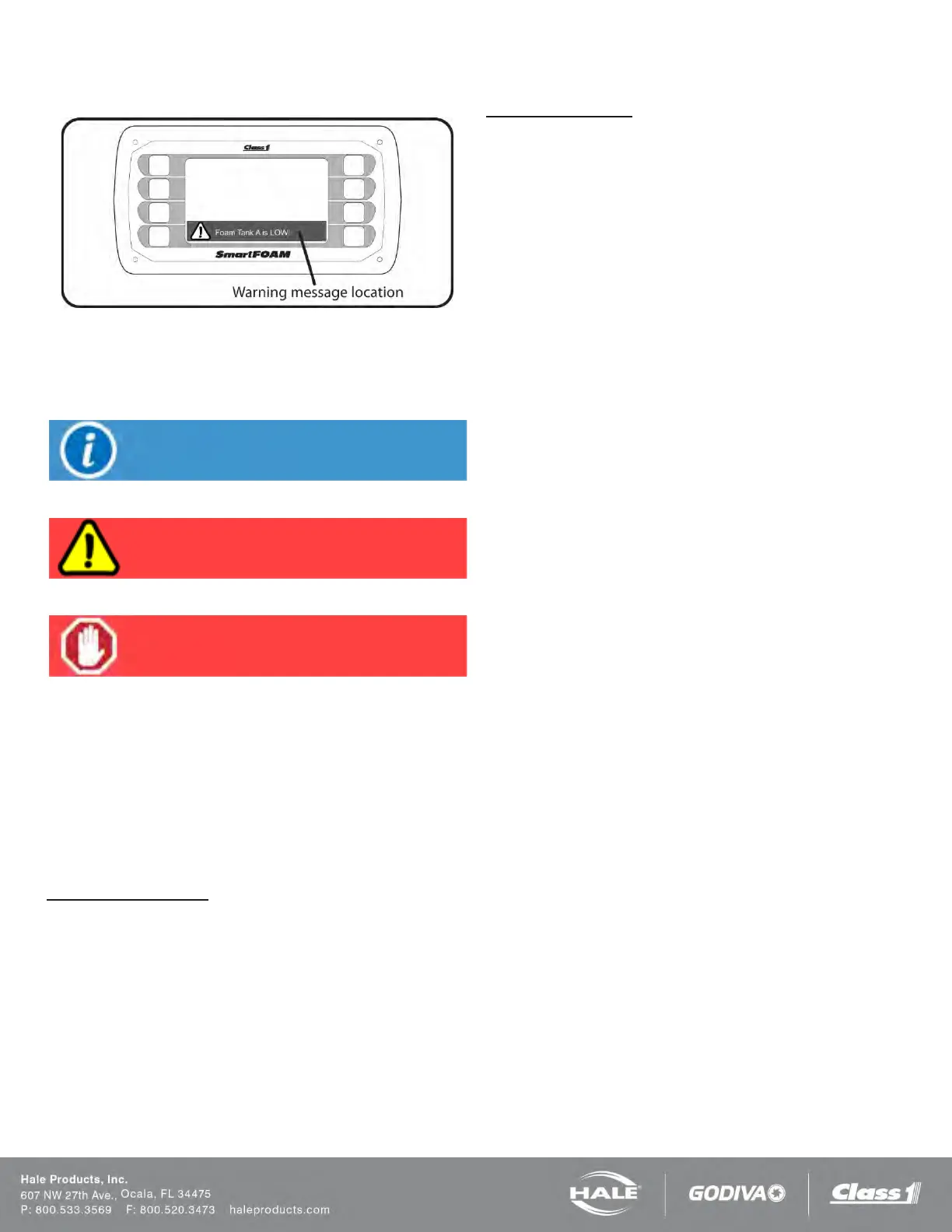

Figure 68: Warning Message Location

This warning ribbon also contains an icon to inform the opera-

tor of the severity of the warning.

Informational

Caution

Operation Halted

The warning ribbon will contain text informing the operator of

what has happened, what will happen, or what the operator

needs to do.

A warning message may be dismissed by pressing the

screen anywhere on the warning ribbon. If the warning is

still active the warning message will appear again after the

inhibit time has expired (default is 60 seconds – configurable

in the OEM menu).

Low Foam Tank Level

The Hale SmartFOAM foam pump is interlocked with the

foam concentrate tank level switch. When the low level

switch is activated (foam tank is empty) the low tank caution

message will be shown and the foam pump will continue to

run for 60 seconds. At the 60 second limit the system and

pump will be forced OFF and the foam is empty operation

halted message will be displayed.

If the ON button is pressed before refilling the foam tank, the

system runs for 30 seconds before shutting down again and

showing the foam is empty operation halted message.

Foam Priming Error

In the event there is no foam feedback signal being received

when the foam pump starts (indicating a lack of foam con-

centrate flow) the foam pump motor ramps up to full speed

attempting to establish foam concentrate flow. The attempt-

ing to prime caution message will appear informing the oper-

ator how many seconds the system will continue to run be-

fore shutting down due to loss of foam prime.

If the system operates for a period of 35 seconds (configura-

ble in the Factory menu) without a feedback signal the sys-

tem turns itself OFF and shows the loss of prime operation

halted message.

PRIMING THE FOAM PUMP

In some instances, the foam tank may run dry while operat-

ing the Hale SmartFOAM system. The foam pump is de-

signed to pump liquid. When the fire pump is running the

foam pump may not pump efficiently against 100 to 150 PSI

(7 to 10 BAR) back pressure. To re-establish foam concen-

trate flow quickly the following procedure is used.

1. Turn the bypass valve to the BYPASS position.

2. With the fire pump flowing water from foam dis-

charge and the Hale SmartFOAM ON, observe the

hose from the bypass valve.

3. When foam concentrate flows from the hose turn the

bypass valve back to the INJECT position.

4. The pump is now primed and ready for normal oper-

ation.

NORMAL OPERATION SUMMARY

Refer to Figure 66 for images of the preset and operation

screens and their associated buttons.

1. Energize the system.

a. Apply power to the apparatus. The Smart-

FOAM controller initializes and shows the

preset screen.

2. Select foam tank (excluding 1.7AHP and 2.1A sys-

tems).

a. If the system is equipped with dual foam

tanks, place the selector to the desired tank.

3. Begin foam injection.

a. Establish water flow and then press one of

the preset buttons on the preset screen.

Operation may also be started by pressing

the HOME button to go to the operation

screen and then press the ON button.

Loading...

Loading...