Page 72

SYSTEM INSTALLER START-UP

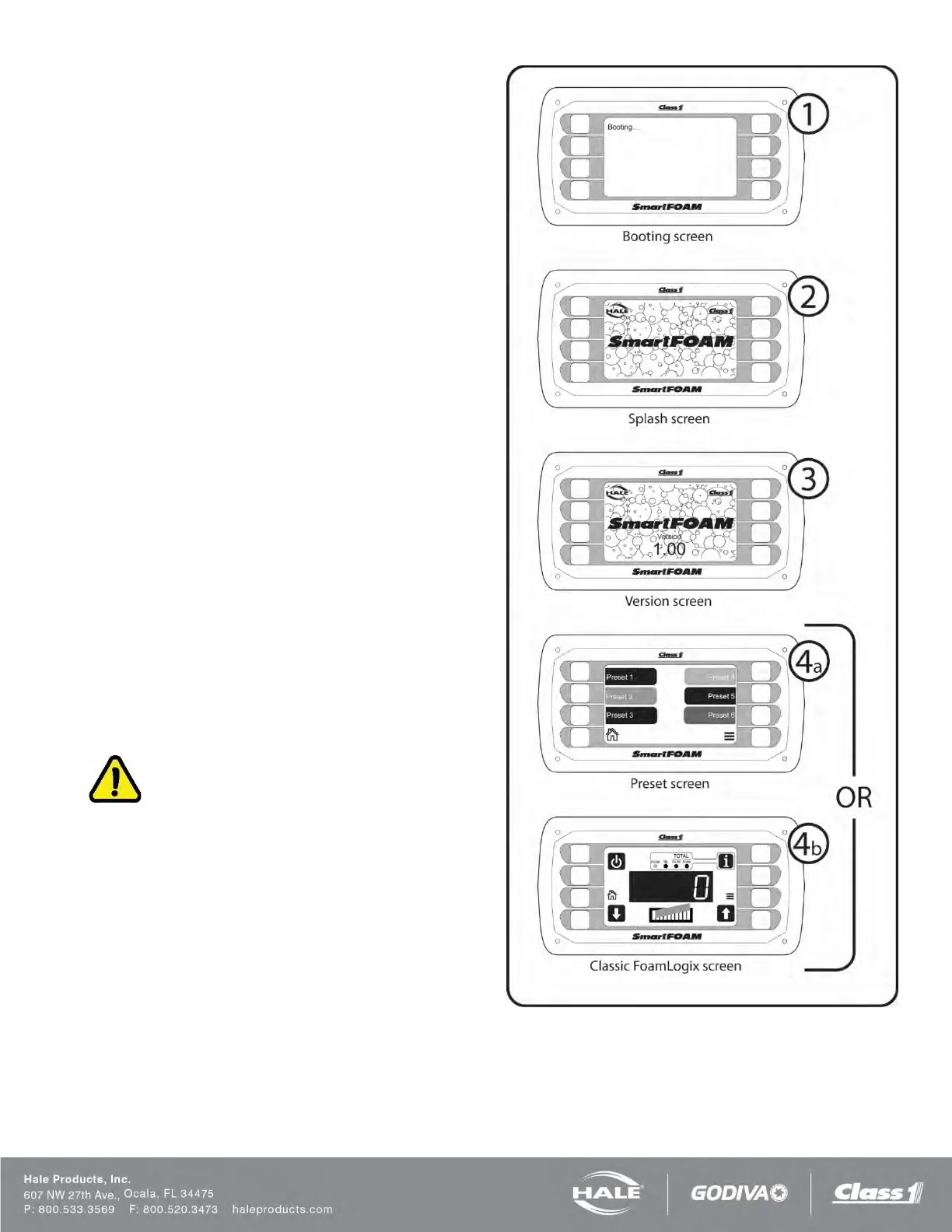

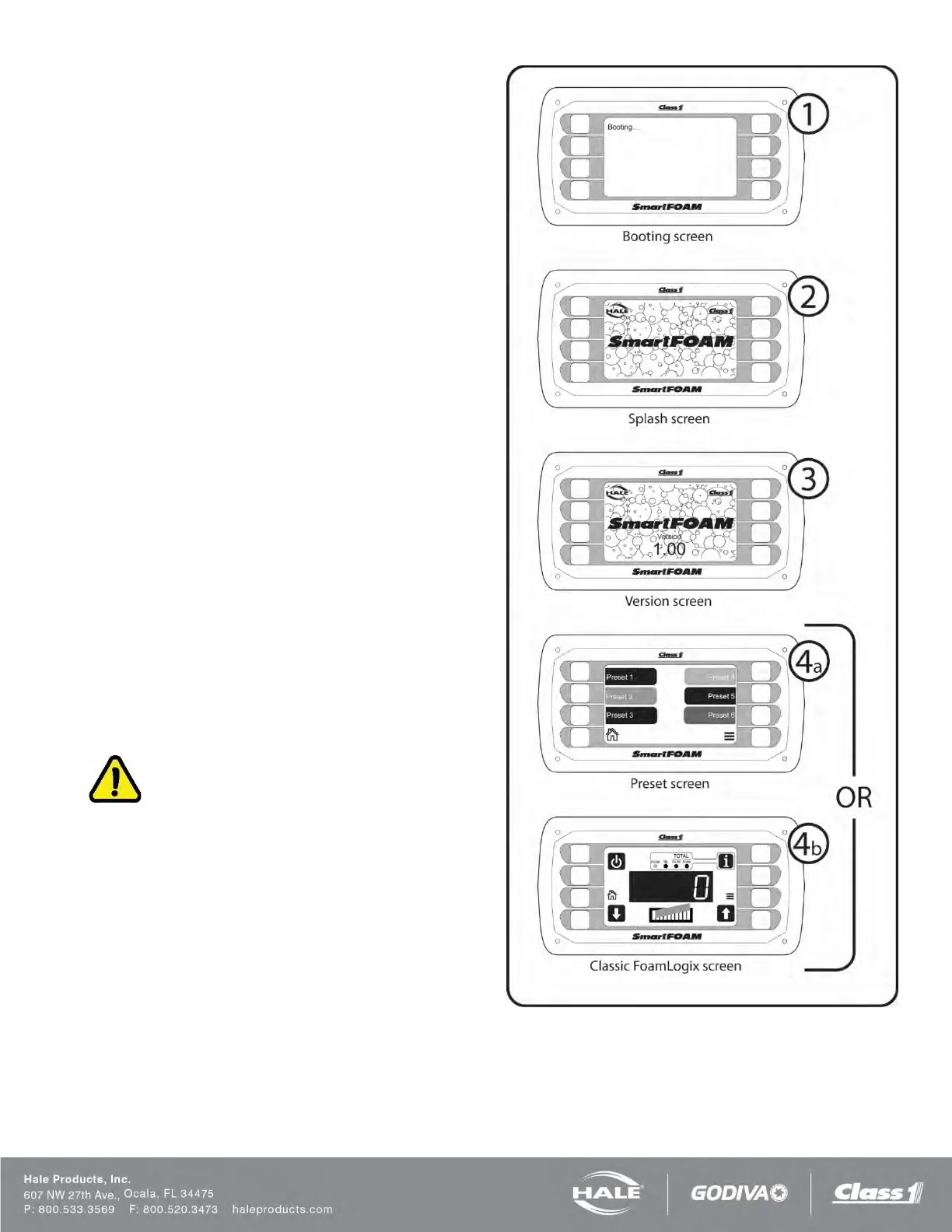

On initial power-up of the Hale SmartFOAM system at

the installer facility, the following procedures must be fol-

lowed.

INITIAL SYSTEM POWER CHECK

Watch the display on the controller unit as the apparatus

electrical system is turned ON. Check the controller unit

readout for:

❑ SmartFOAM booting screen is shown for three

seconds.

❑ SmartFOAM splash screen is shown for three

seconds.

❑ SmartFOAM version screen is shown for two

seconds.

❑ SmartFOAM preset screen is shown (default)

OR

SmartFOAM classic FoamLogix screen is

shown.

(The screen shown depends on the “display for-

mat” chosen in the user menu).

(See Figure 57).

If a default display does not appear, refer to the TROU-

BLESHOOTING section for possible WARM-UP/ SYS-

TEM CHECKING causes and solutions.

INITIAL SYSTEM CHECK

After initial system power-up the low tank level sensor

operation, foam pump operation, and flow sensor cali-

bration must be checked per the following:

CAUTION!

WATER IS USED AT THE SYSTEM INSTALLER FA-

CILITY TO VERIFY LOW TANK LEVEL SENSOR SYS-

TEM READY OPERATION AND FOAM PUMP OPERA-

TION AS THE END USER SPECIFIED FOAM

CONCENTRATES MAY NOT BE READILY AVAILA-

BLE.

DO NOT PUMP WATER WITH THE HALE FOAM-

LOGIX FOAM PUMP FOR MORE THAN ONE (1) MI-

NUTE. DO NOT ATTEMPT TO CALIBRATE FOAM

PUMP FEEDBACK SENSOR WITH OTHER THAN

END USER SPECIFIED FOAM CONCENTRATE.

MAKE SURE THE BYPASS VALVE IS IN THE BY-

PASS POSITION WHEN PUMPING WATER WITH THE

FOAM PUMP.

Figure 57: Controller Unit Initialization

Loading...

Loading...