Page 48

WATERWAY CHECK VALVES

Check valves in the waterway, rated at 500 PSI

(34.5 BAR), are required to keep foam solution out of the

main pump and allow pump priming without drawing

foam into the piping.

Using double check valves, separated by at least 6” to 8”

(152 to 203 mm) of pipe before the foam injection point,

ensures that the pump and tank water remain uncontam-

inated.

FLOW SENSOR

The Hale SmartFOAM flow sensor is specially designed

to enable quick and easy sensor inspection and mainte-

nance. The flow sensor paddle wheel is installed on a

saddle clamp or weld fitting to the foam-capable dis-

charge piping of the apparatus.

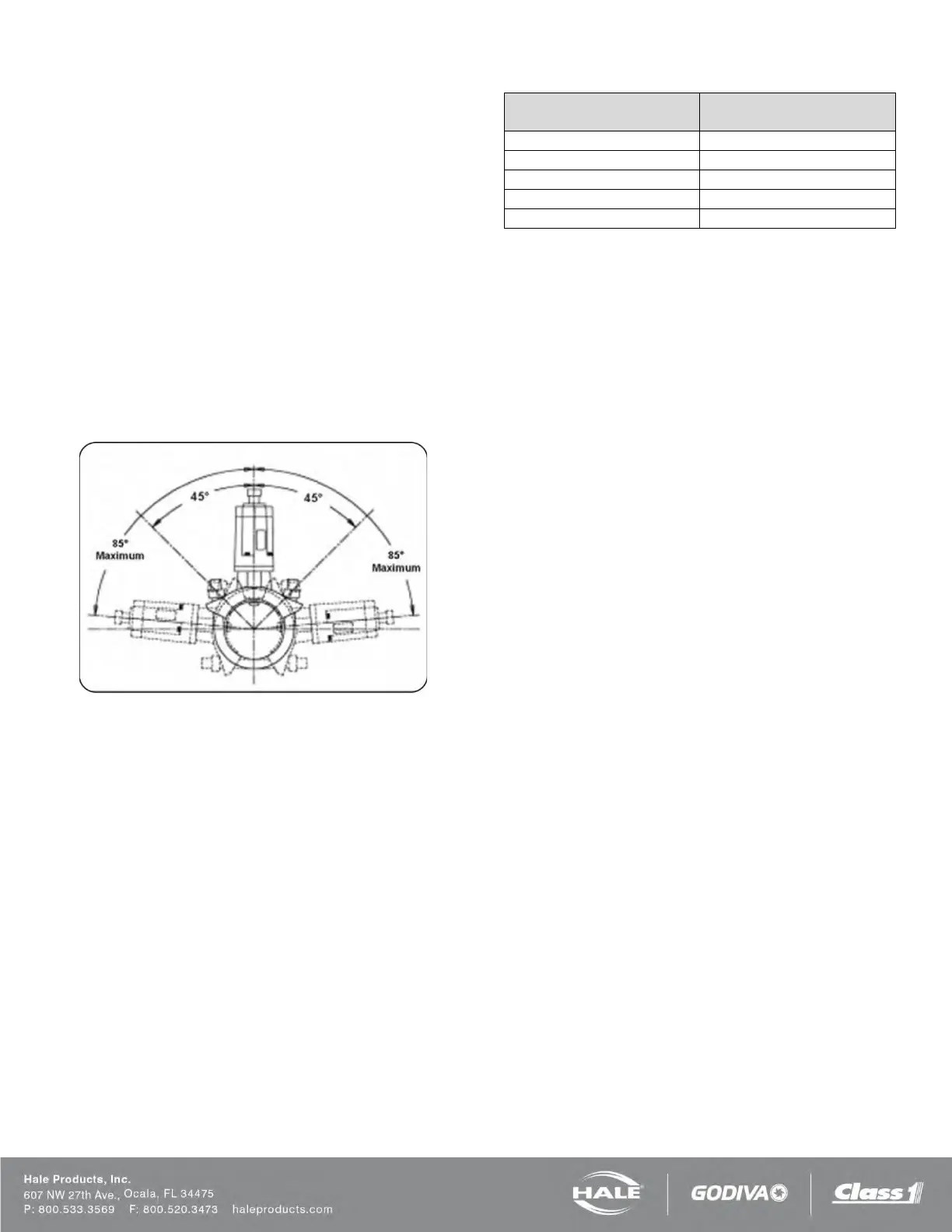

In horizontal piping runs, the flow sensor is mounted

within the range shown in Figure 29.

Figure 29: Flow Sensor Tee Position Range

When selecting a flow sensor, it is important to consider

the minimum and maximum flow requirements during op-

eration. Refer to Table 5: Pipe Size Versus Flow

Range, for the proper pipe size for flow range desired.

The flow sensor is installed in the piping before the foam

concentrate injection point.

This is true in applications where the foam system

needs

to supply a 3” (76 mm) deck gun, as well as a 1”

(25.4 mm) booster line.

Table 7: Pipe Size versus Minimum Straight Run

Pipe Size

Minimum Recommended

Straight Run Pipe

Pipe size for flow sensor mounting must be selected to

provide accuracy at the lowest flow rate. Mounting the

flow sensor in a short section of pipe, one pipe size

smaller (e.g., 4” to 3”; 3” to 2-1/2”, etc.), provides better

accuracy at the lower flows.

Refer to the Table 7: Pipe Size versus Minimum

Straight Run” for pipe size. Selecting the next smaller

pipe permits reducing the straight pipe run the required

distance prior to the flow sensor paddle wheel.

In the short length of reduced pipe pressure loss is mini-

mal and there is minimal pressure loss through elbows

and fittings (Figure 30).

Excessive turbulence in the flow sensor may produce

unstable and inaccurate flow readings. The length of

straight pipe prior to the flow sensor must be sufficient to

reduce any turbulence in the pipe.

The following guidelines help attain the best readings,

and maintain Hale SmartFOAM system

accuracy.

1. A minimum of 6 times the pipe diameter of

straight run pipe without any fittings is necessary

prior to the flow sensor paddle wheel (Figure

31).

2. The downstream piping length is not as critical,

but there must be a short length of straight pipe

with no fittings or valves immediately after the

flow sensor paddlewheel. Two to three times the

pipe diameter is recommended.

3. Do not mount a flow sensor directly after an el-

bow or valve. Valves create severe turbulence

when they are “Gated”.

Loading...

Loading...