Page 77

USER CALIBRATION

The complete Hale SmartFOAM Systems foam pump

and motor assembly, controller unit and flow sensor is

tested at the factory before shipping to the installer.

If the

Hale SmartFOAM system is properly installed, further

calibration IS NOT necessary until delivery to

customer.

The system permits easy checking of component calibra-

tion to assure accurate operation. The calibration pro-

cess verifies component calibration and allows adjust-

ments to the flow sensor and feedback sensor display

readings to allow for

variations in apparatus piping con-

figurations and end user selected foam concentrate.

Default values for simulated flow and foam concentrate

injection rate may be set to end user specifications while

in the calibration mode.

The SmartFOAM controller allows up to 6 user preset

foam injection rates. Each preset allows for custom text

and color for easy identification.

Note: The Hale SmartFOAM system is calibrated at the

factory to U.S. measurement (GPM, PSI,

GALLONS,

etc.) units. The system may be set

to Metric units (see

heading “English to Metric Units”). However, the same

unit of measurement must be used throughout the cali-

bration process to ensure proper proportioning by the

system.

Recalibration of the system may be required ONLY

after

major repairs or component changes are made to the

Hale SmartFOAM foam system. Different viscosity foam

concentrates may also require recalibration.

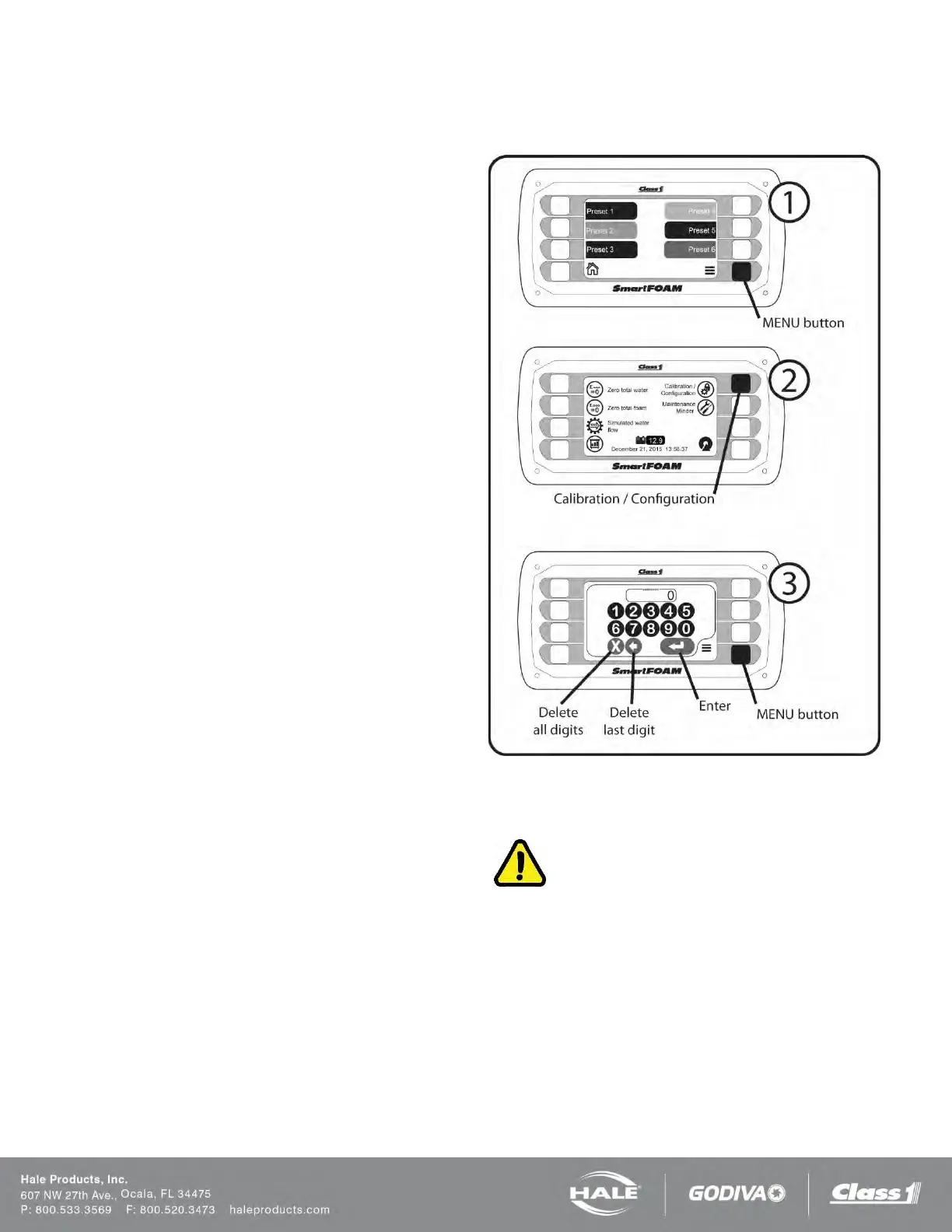

ENTERING PASSWORDS

System calibration and configuration is accomplished by

accessing screens which are protected via passwords.

To enter a password:

1. Press the MENU button to go to the system

menu.

2. Press the Calibration/Configuration button on the

system menu screen.

3. Use the touch screen keypad to enter the de-

sired password.

a. Press the “Enter” touch screen button to

submit the password.

b. Press the “Delete last digit” touch screen

button to erase the last digit entered.

c. Press the “Delete all digits” touch screen

button to erase all of the digits entered.

When a valid password is submitted the screen will auto-

matically change to the screen dictated by the password

value.

If an invalid password is submitted the display will show an “X”

across the password window for two seconds.

F

igure 61: Entering Passwords

WATER FLOW CALIBRATION

IMPORTANT!

AN ACCURATE FLOW MEASURING DEVICE MUST BE

USED TO MEASURE THE WATER FLOW WHEN CALIBRAT-

ING THE FLOW SENSOR. USE A SUITABLE SIZE, SMOOTH

BORE, NOZZLE AND AN ACCURATE AND CALIBRATED PI-

TOT GAUGE INSTRUMENT. HANDHELD PITOT GAUGES

ARE USUALLY NOT VERY ACCURATE.

MAKE SURE THE SYSTEM IS CALIBRATED WITH AN AC-

CURATE FLOW MEASURING DEVICE.

Enter the password “6679”. The controller will show the water

flow calibration screen.

Water flow calibration requires setting two calibration points: one

at a high rate of flow and the second at a lower rate of flow.

Loading...

Loading...