127

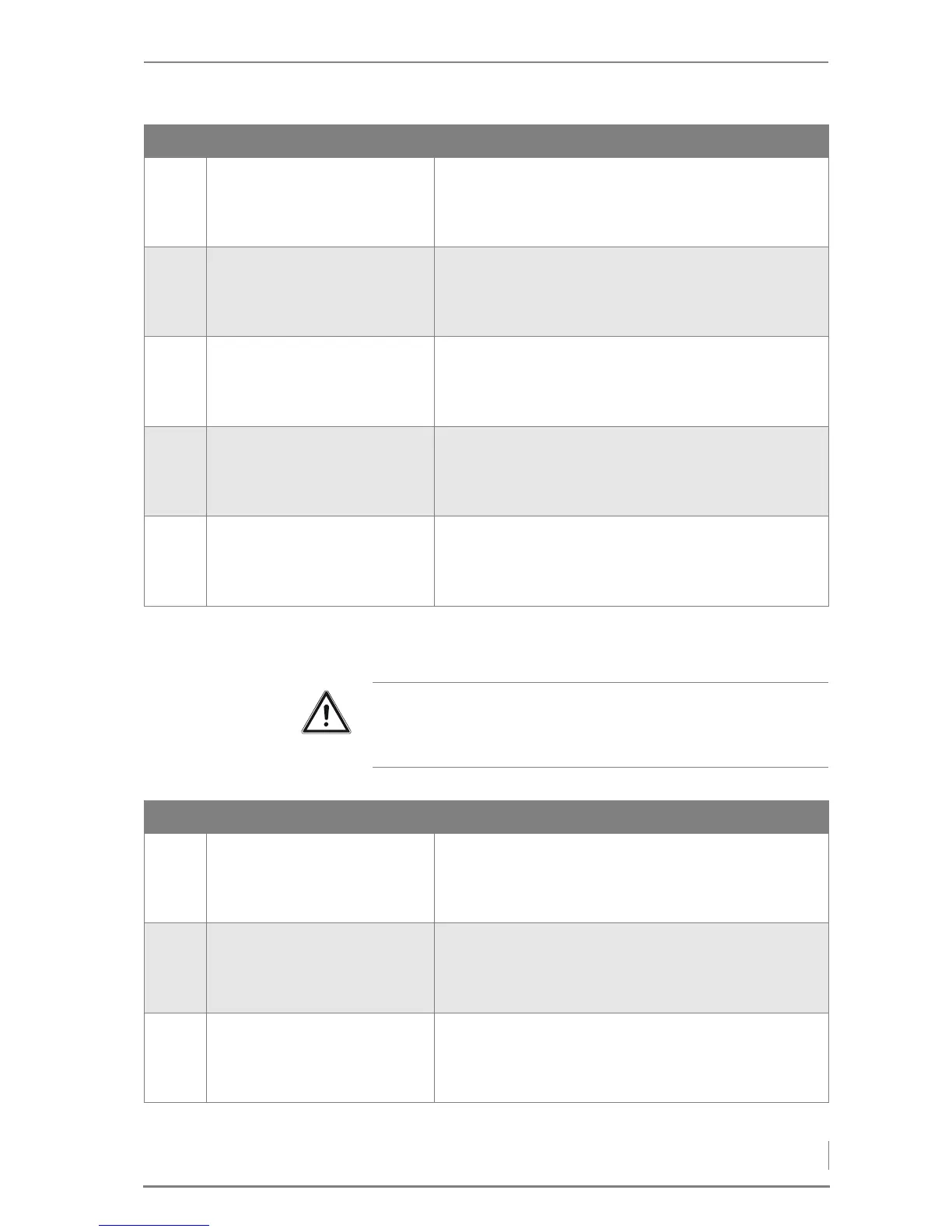

5 - RETURN

4-33 Control

O2 fuel change

delta Minimum

( -10) -10%

• Fuel change due to residual oxygen

If the residual oxygen is too low, the specified percentage

value is deducted from the fuel quantity.

(-50 - -100 %)

4-34 Control

O2 fuel change

delta Maximum

( 10) 10%

• Fuel change due to residual oxygen

If the residual oxygen is too low, the specified percentage

value is added to the fuel quantity.

(50 - 100 %)

4-35 Controller info

no

yes

• Controller info

If set to “yes”, additional menu windows are displayed

with current controller values.

4-36 Control

Combustion

fan speed

( 80) 80%

• Input for combustion fan speed

(0 - 100%)

4-37 Control

Combustion fan

speed Log wood

( 50) 50%

• Input for combustion fan speed

For “Log wood” emergency operation.

(0 - 100%)

No. Display Description

Table 6/6 - System level / 4 - Control

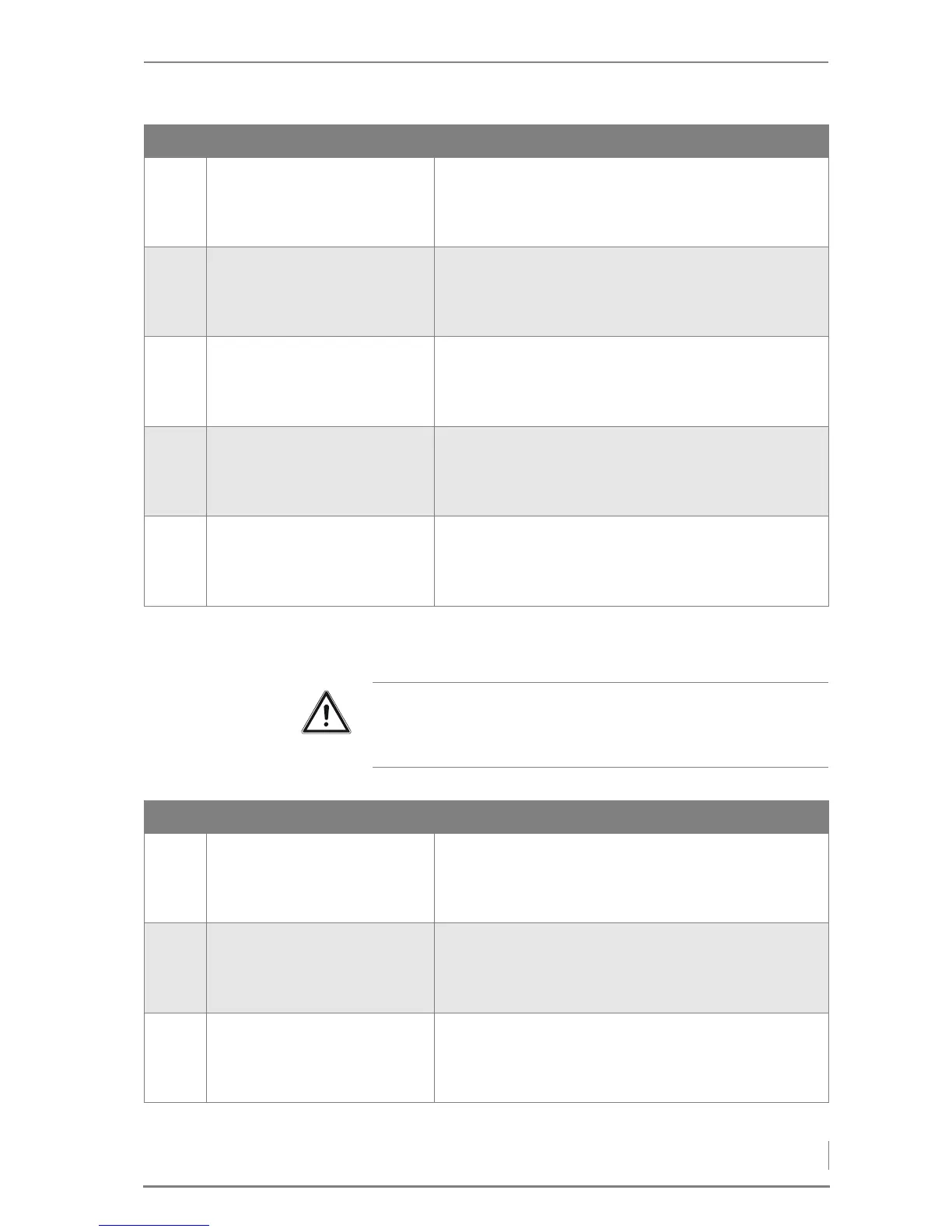

Warning!

Falling below dew point

Do not set the return temperature below 60 °C.

No. Display Description

5-01 Return

Pumps on/off at

boiler temperature

( 57) 57°

• Enabling of the return pump

If the boiler temperature is above this setting, the return

pump is enabled.

(40 - 80 °C)

5-02 Return

Mixing valve

total runtime

( 150) 150s

• Total runtime of return flow mixer

Set the total runtime of the return flow mixing valve.

(100- 600 s)

5-03 Return

Mixing valve

Minimum runtime

( 3) 3s

• Minimum runtime of return flow mixer

Set the minimum runtime of the return flow mixing valve.

(1 - 100 s)

Table 6/7 - System level / 5 - Return

Loading...

Loading...