83

Refrigerant Piping Work

4. Refrigerant Piping Work

●

Use refrigerant R410A in the refrigerant cycle.

Do not charge oxygen, acetylene or other ammable and poisonous gases into the refrigerant cycle when

performing a leakage test or an air-tight test. These types of gases are extremely dangerous and can cause an

explosion. It is recommended that compressed air, nitrogen be used for these types of tests.

●

Check to ensure that no pressure exists inside the stop valve before removing the ange.

Ensure to connect the piping among the units in the same refrigerant cycle

4.1 Piping Materials

(1) Prepare copper pipes to be supplied in the locality.

(2) Select the piping size from this handbook.

(3) Select clean copper pipes. Make sure there is no dust and moisture inside the pipes. Purge pipes with nitrogen or dry air

to remove any dust or foreign matters before connecting pipes. Do not use any tools which produce a lot of swarf such

as a saw or a grinder.

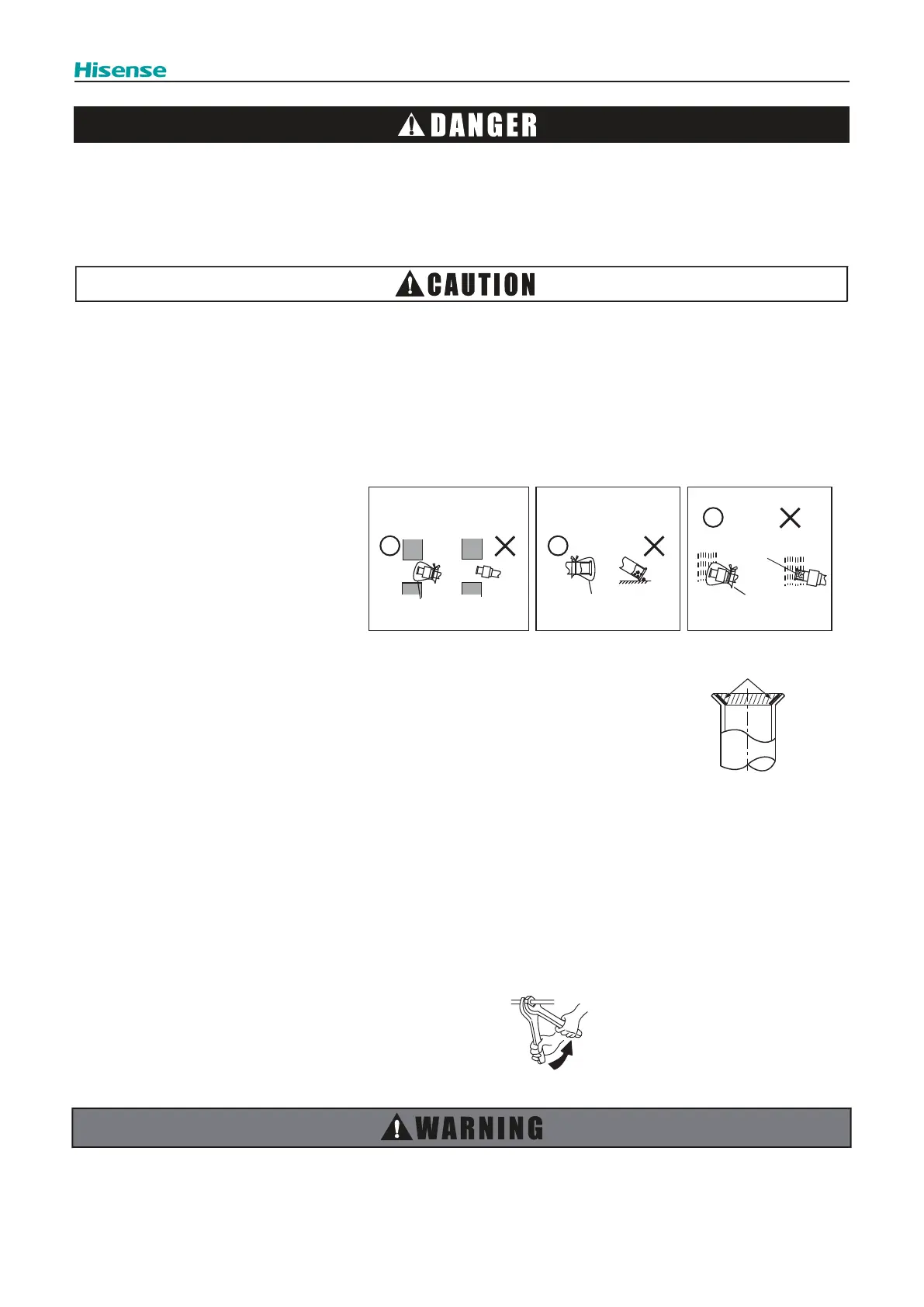

● Cautions for Refrigerant Pipe Ends

When installing pipe through the wall, secure

a cap at the end of the pipe.

Correct Incorrect

Hole Hole

Attach a cap or vinyl tape.

Do not place the pipe directly on the

ground

Correct Incorrect

Attach a cap or vinyl tape.

Correct

Incorrect

Rain water can enter

Attach a cap or

vinyl bag with

rubber band.

● Cautions for Piping Connection Work

(1) Connect the indoor/outdoor units with refrigerant pipes. Fix the pipes and pay attention not to

contact with weak materials such as ceiling. Otherwise, vibration of piping may give o abnormal

sound.

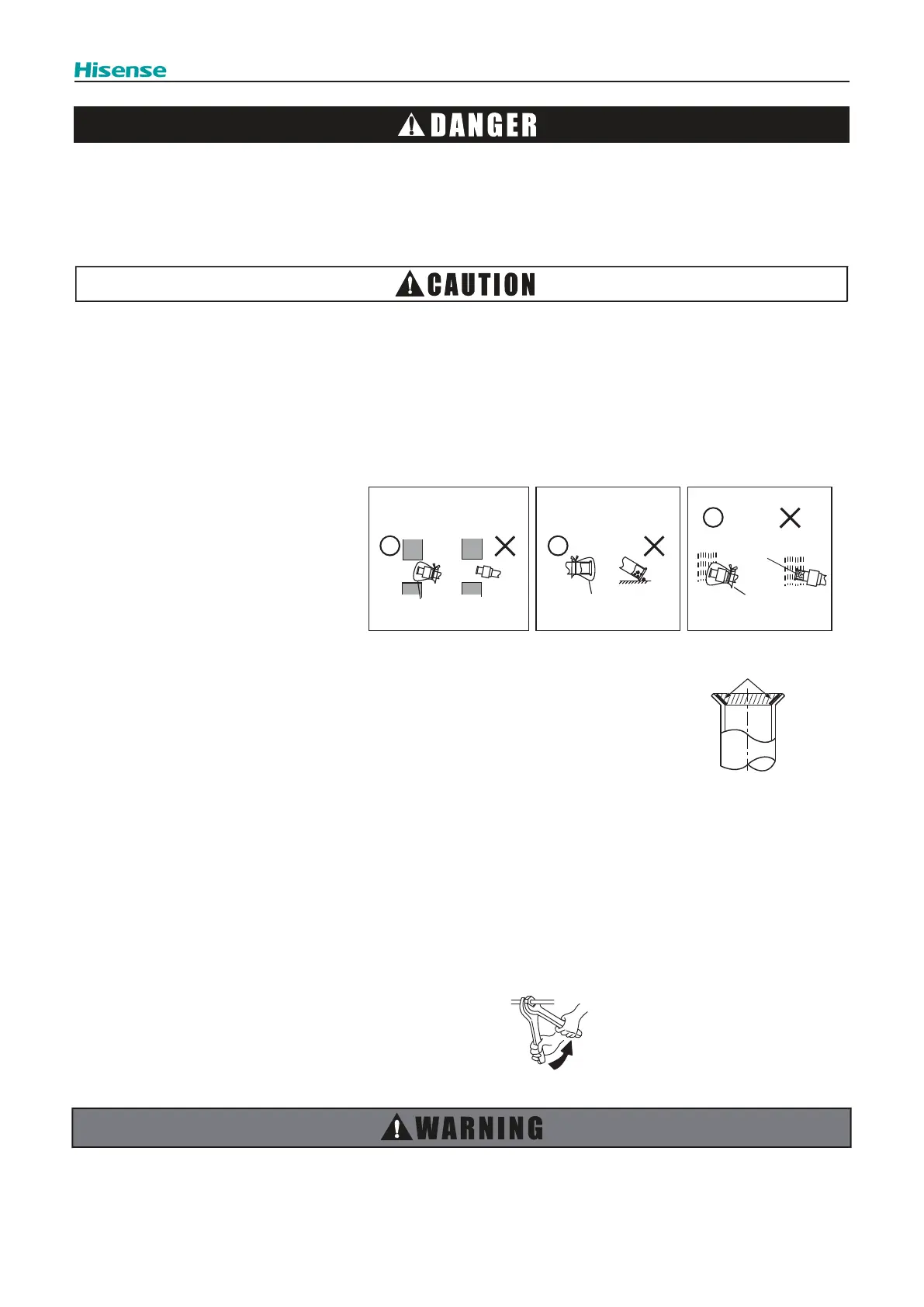

(2) Apply refrigerant oil slightly on the sheet surface of the pipe and are nut before the aring work.

Tighten the are nut by two wrenches with the specied tightening torque. Perform the

aring work on the liquid piping then on the gas piping. Check the gas leakage after the aring

work.

Apply Refrigerant Oil

NOTE:

Refrigerant oil is eld-supplied.

【

Model: FVC68D

】

(3) In case that temperature and humidity inside the ceiling exceed 81°F(27°C)/RH80%, apply additional insulation with

thickness around 24/65in.(10mm) to the accessory insulation. It prevents dew condensation on the surface of the

insulation (refrigerant pipe only).

(4) Perform the air-tight test (601psi(4.15MPa) for the test pressure).

(5) Perform cold insulation work by insulating and taping the are connection and reducer connection. Also insulate all the

refrigerant pipes.

● When tightening the are nut, use two wrenches.

with two wrenches

Do not apply excessive force to the are nut when tightening. Otherwise, the are nut

may crack due to aged deterioration and refrigerant leakage may occur. Use the specied

tightening torque.

Loading...

Loading...