84

Refrigerant Piping Work

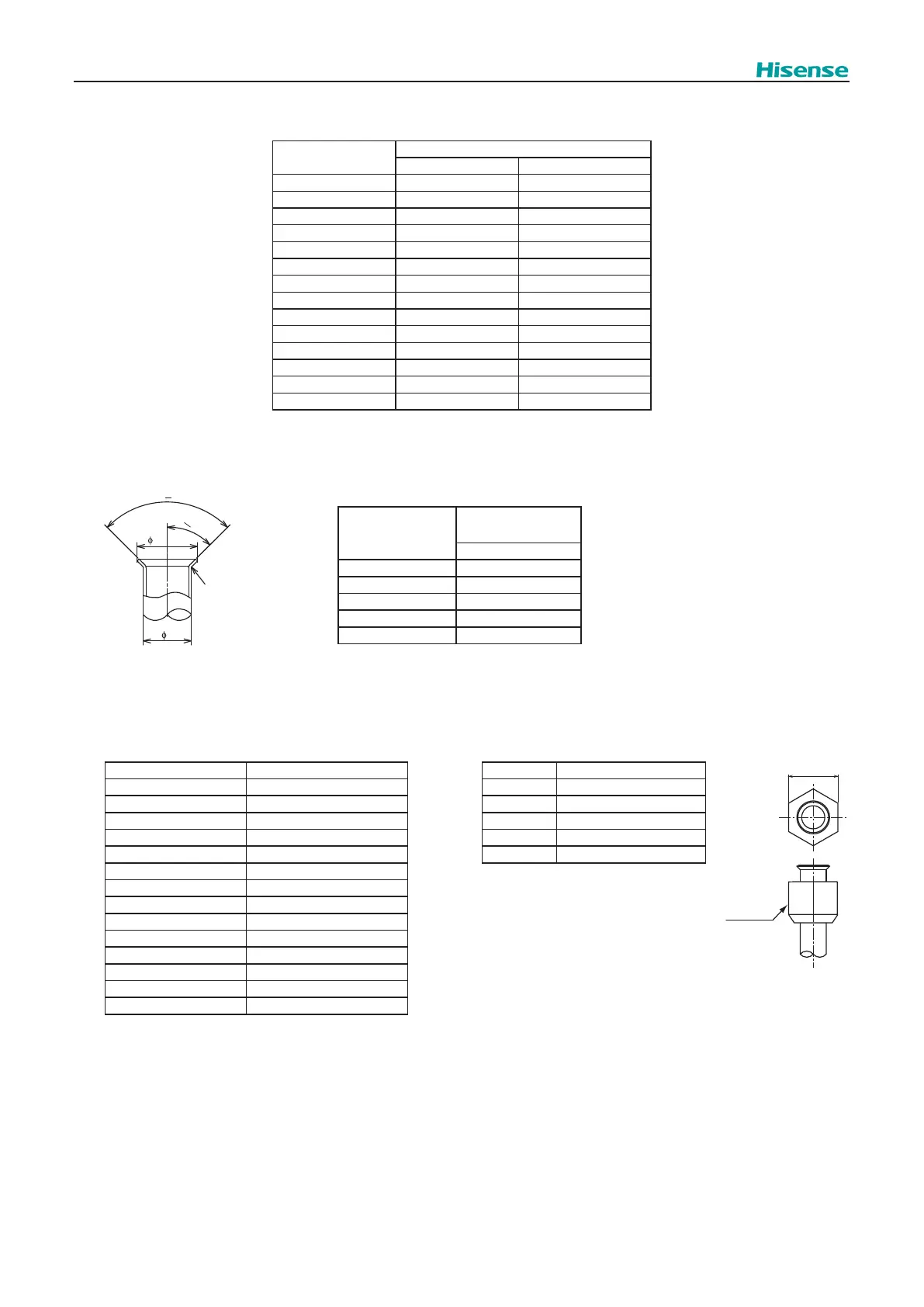

● Piping Thickness and Material

Use the pipes as below.

unit:in.(mm)

Diameter

R410A

Thickness Material

Φ1/4(6.35) 1/32(0.8) O material

Φ3/8(9.53) 1/32(0.8) O material

Φ1/2(12.7) 1/32(0.8) O material

Φ5/8(15.88) 3/64(1.0) O material

Φ3/4(19.05) 3/64(1.0) 1/2H material

Φ7/8(22.2) 3/64(1.0) 1/2H material

Φ1(25.4) 3/64(1.0) 1/2H material

Φ1-1/8(28.6) 3/64(1.0) 1/2H material

Φ1-1/4(31.75) 3/64(1.1) 1/2H material

Φ1-1/2(38.1) 3/64(1.35) 1/2H material

Φ1-5/8(41.3) 1/16(1.45) 1/2H material

Φ1-3/4(44.5) 1/16(1.55) 1/2H material

Φ2(50.8) 5/64(2.0) 1/2H material

Φ2-1/8(53.98) 5/64(2.0) 1/2H material

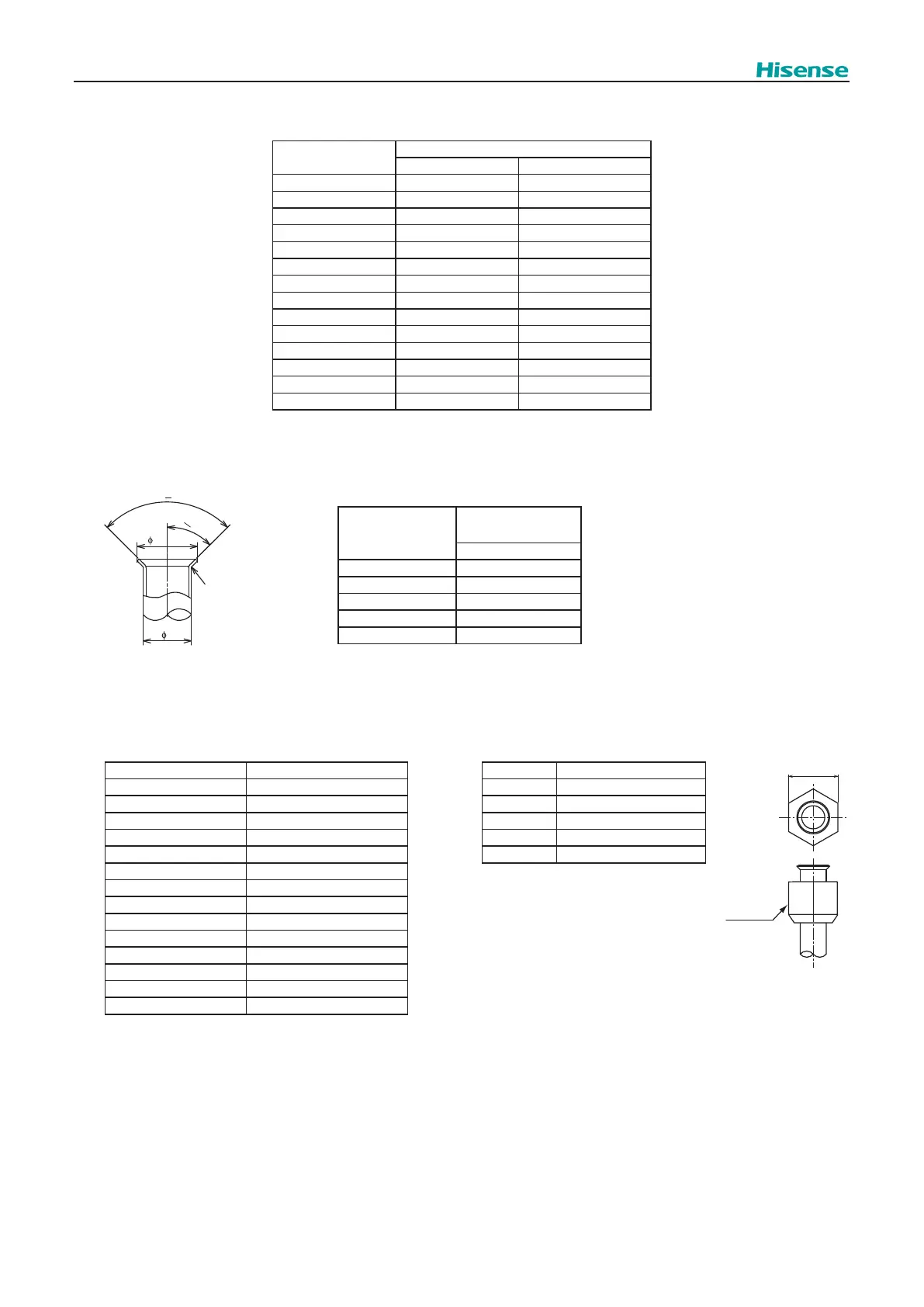

4.2 Flaring and Joint

● Flaring Dimension

Perform the aring work as shown below.

unit: in.(mm)

Diameter (Φd)

A

1/64

+0

(*)It is impossible to perform

aring work with 1/2H material.

In this case, use an accessory

pipe (with a are)

R410A

1/4(6.35) 23/64(9.1)

3/8(9.53) 33/64(13.2)

1/2(12.7) 21/32(16.6)

5/8(15.88) 25/32(19.7)

3/4(19.05) (*)

● Joint Selection

If you use 1/2H material, you can not perform aring work. In this case, use a joint selected from the chart below.

<Minimum Thickness of Joint (in.(mm))> < Flare Nut Dimension B (in.(mm))>

Diameter R410A Diameter R410A

Φ1/4(6.35) 1/64(0.5) Φ1/4(6.35) 43/64(17)

Φ3/8(9.53) 1/32(0.6) Φ3/8(9.53) 55/64(22)

Φ1/2(12.7) 1/32(0.7) Φ1/2(12.7) 1-1/32(26)

Φ5/8(15.88) 1/32(0.8) Φ5/8(15.88) 1-9/64(29)

Φ3/4(19.05) 1/32(0.8) Φ3/4(19.05) 1-27/64(36)

Φ7/8(22.2) 1/32(0.9)

Φ1(25.4) 1/32(0.95)

Φ1-1/8(28.6) 3/64(1.0)

Φ1-1/4(31.75) 3/64(1.1)

Φ1-1/2(38.1) 3/64(1.35)

Φ1-5/8(41.3) 1/16(1.45)

Φ1-3/4(44.5) 1/16(1.55)

Φ2(50.8) 5/64(2.0)

Φ2-1/8(53.98) 5/64(2.0)

B

Flare Nut

90

o

+

2

o

1/64(0.4)~1/32(0.8)R

A

d

45

o

+

2

o

Loading...

Loading...