7-22

NOTE: • Until break-in operation is performed for more than

50 hours, lubricate the machine every day to get ini

-

tial operational concordance. In case excavation is

made in mud, water or snow, lubricate the machine

after operation is complete.

• Sufficiently add high quality grease through the

grease fittings. After removing contamination

around the grease fitting, add grease. After greasing,

thoroughly remove the old grease that was pushed-

out from the seals.

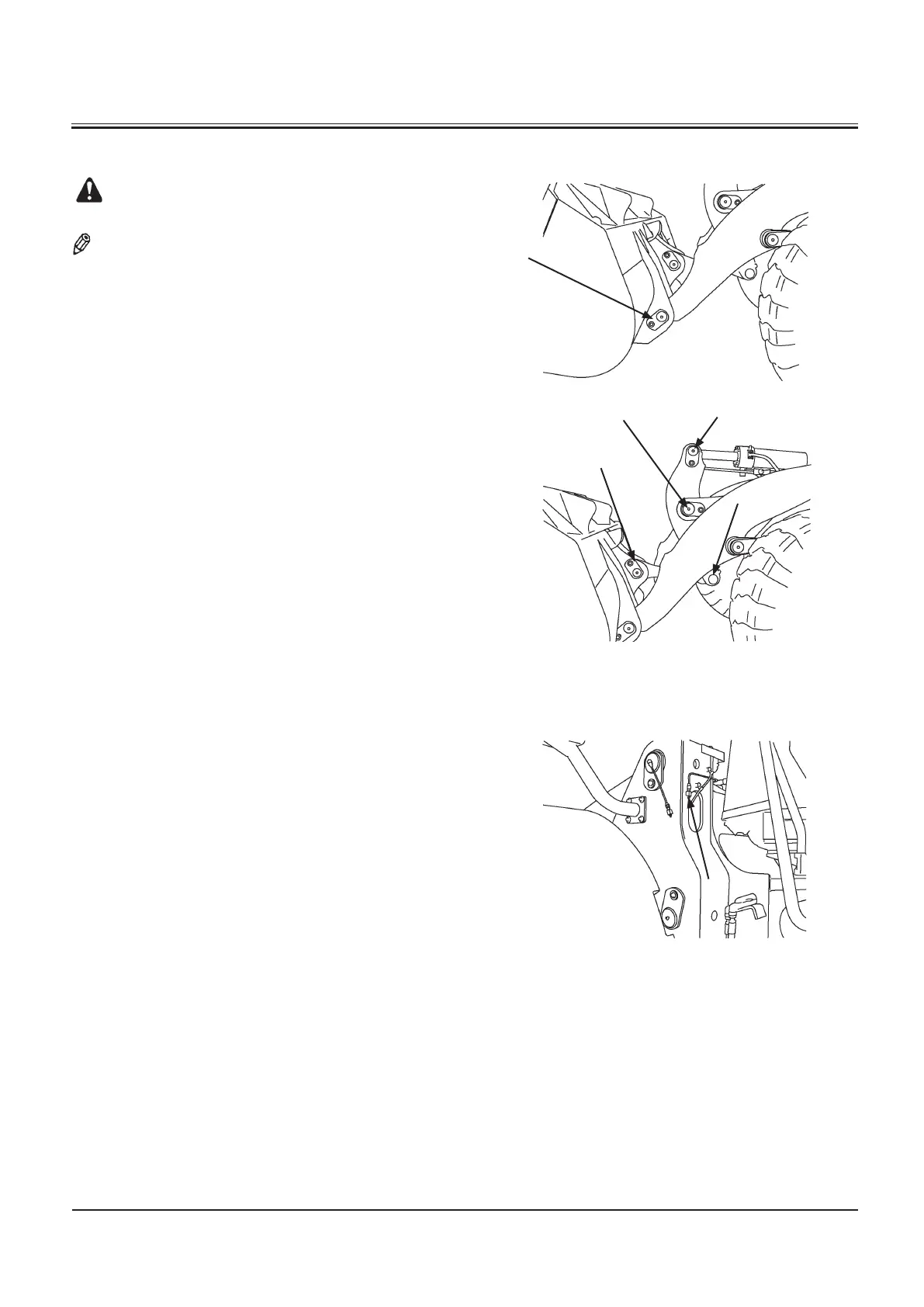

1. Bucket pins (1) (One point each to right and left) :

--- every 500 hours (250 hours at first time only)

2. One point each to bucket links pin (2 and 3):

--- every 500 hours (250 hours at first time only)

3. Bucket cylinder pin (4) One point

--- every 500 hours (250 hours at first time only)

Bucket cylinder rod pin (5) One point

--- every 500 hours (250 hours at first time only)

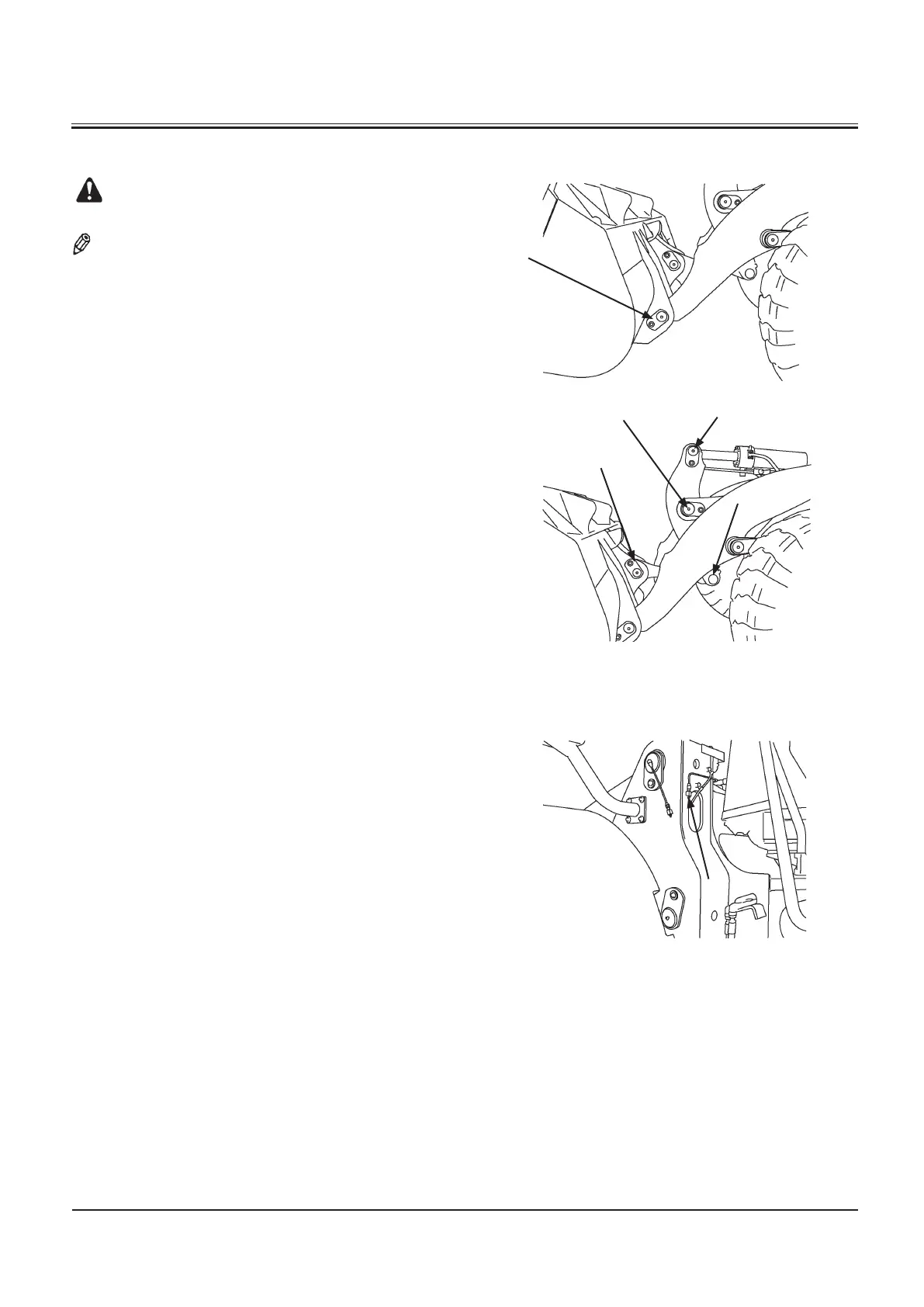

4. Bell crank pin (6) One point

--- every 500 hours (250 hours at first time only)

M4GB-07-004

M4GB-07-005

M4GB-07-006

Loading...

Loading...