7-40

M4GB-07-044

1. Be sure that the machine is parked on a level, firm surface

before servicing hydraulic equipment.

2. Lower the bucket to the ground and stop the engine.

3. Begin servicing hydraulic components only after compo

-

nents, hydraulic oil and lubricants are completely cooled,

and after releasing residual pressure.

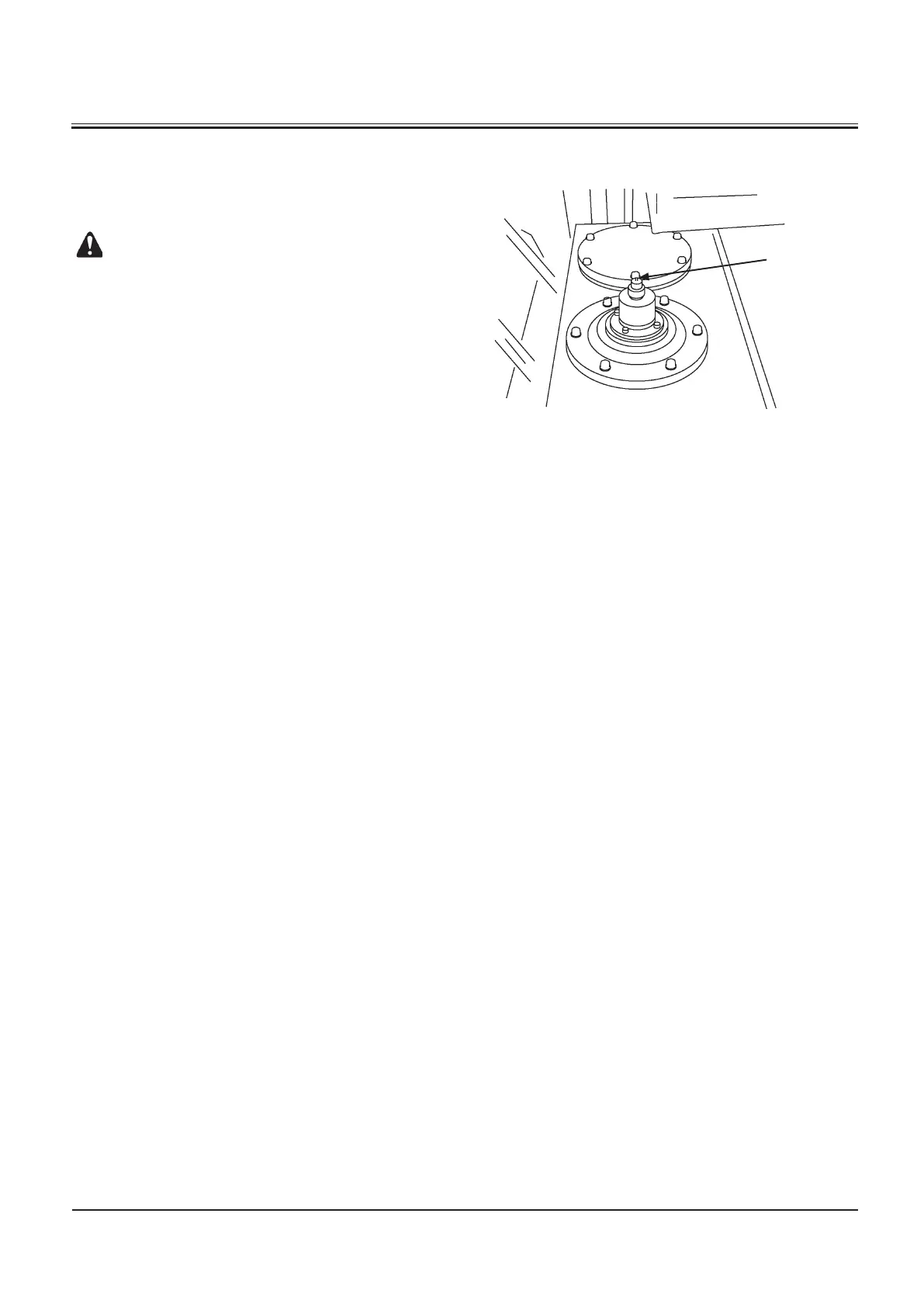

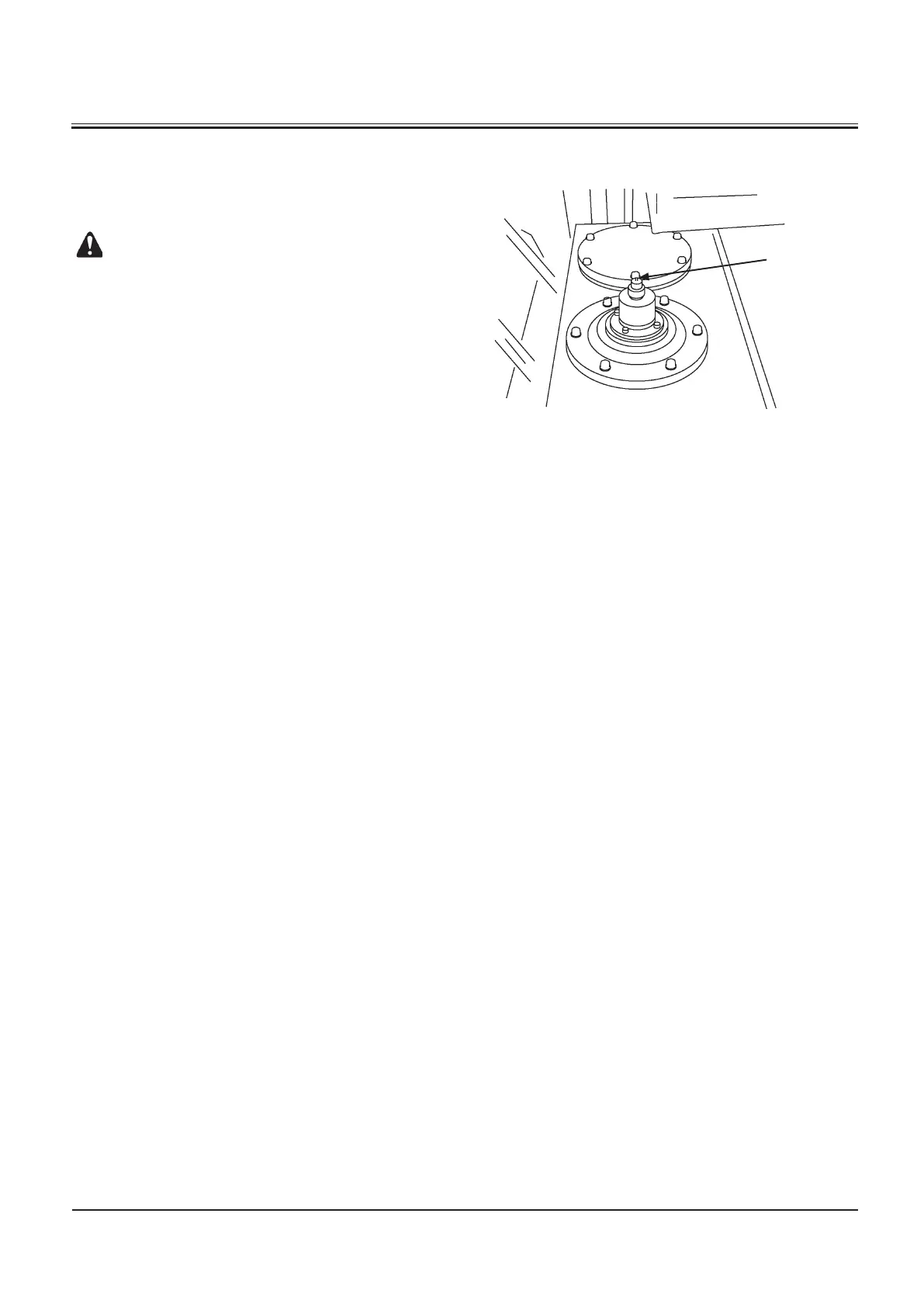

3.1 Bleed air from the hydraulic oil tank to release internal

pressure.

3.2 Be sure to relieve the air pressure from the hydraulic oil

tank by pressing air bleed valve (1).

3.3 Allow the machine to cool down.

Note that servicing heated and pressurized hydraulic

components may cause hot parts and/or oil to fly off or

escape suddenly, possibly resulting in personal injury.

3.4 Keep body parts and face away from plugs or screws

when removing them.

Hydraulic components may be pressurized even when

cooled.

3.5 Never attempt to service or inspect the hydraulic cir

-

cuits on slopes. They are highly pressurized due to self-

weight.

Loading...

Loading...