ADVANCED FEATURES (CONTINUED)

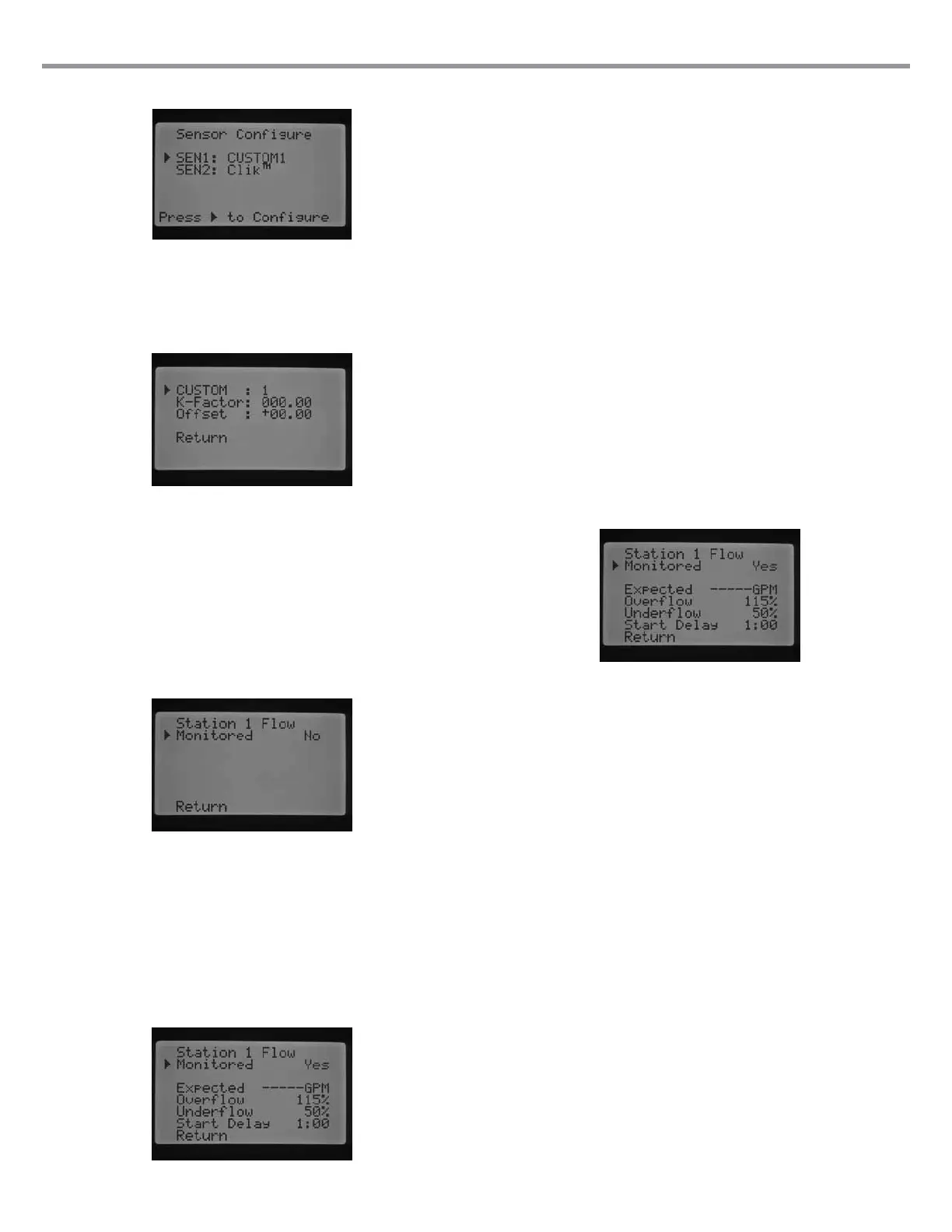

Use the ▲ or ▼ buttons and the ◄ and ► buttons to navigate through

the Custom, K-Factor, and Offset screen. Once you navigate to a number,

it will ash. The number may be changed by pressing the + / – button to

either increase or decrease the value. Once you have completed entering

the K-Factor and Offset specied by the manufacturer of the ow sensor,

use the ▼ button to return to the main Sensor Conguration screen.

If an HFS sensor has been selected and programmed in the Sensor

Conguration screen, the main RUN screen will indicate a ashing ow rate

anytime a station is irrigating. If the station's ow has not been learned or the

station has not been enabled for ow monitoring, which will be discussed

in the Flow Operation and Manual Operation section, the screen will still

indicate a total ow of 0.0 GPM because the HFS has been selected.

Flow Operation

The Flow Operation feature allows you to program ow monitoring

functions for each station. You can program the controller to either monitor

ow for a station or not monitor ow for a station.

1.

Turn the dial to the ADVANCED FEATURES position. Use the ▲ and

▼ to select Flow Operation and use the + button to enter.

2. Use the ◄ and ► buttons to navigate to the station you would like

to program.

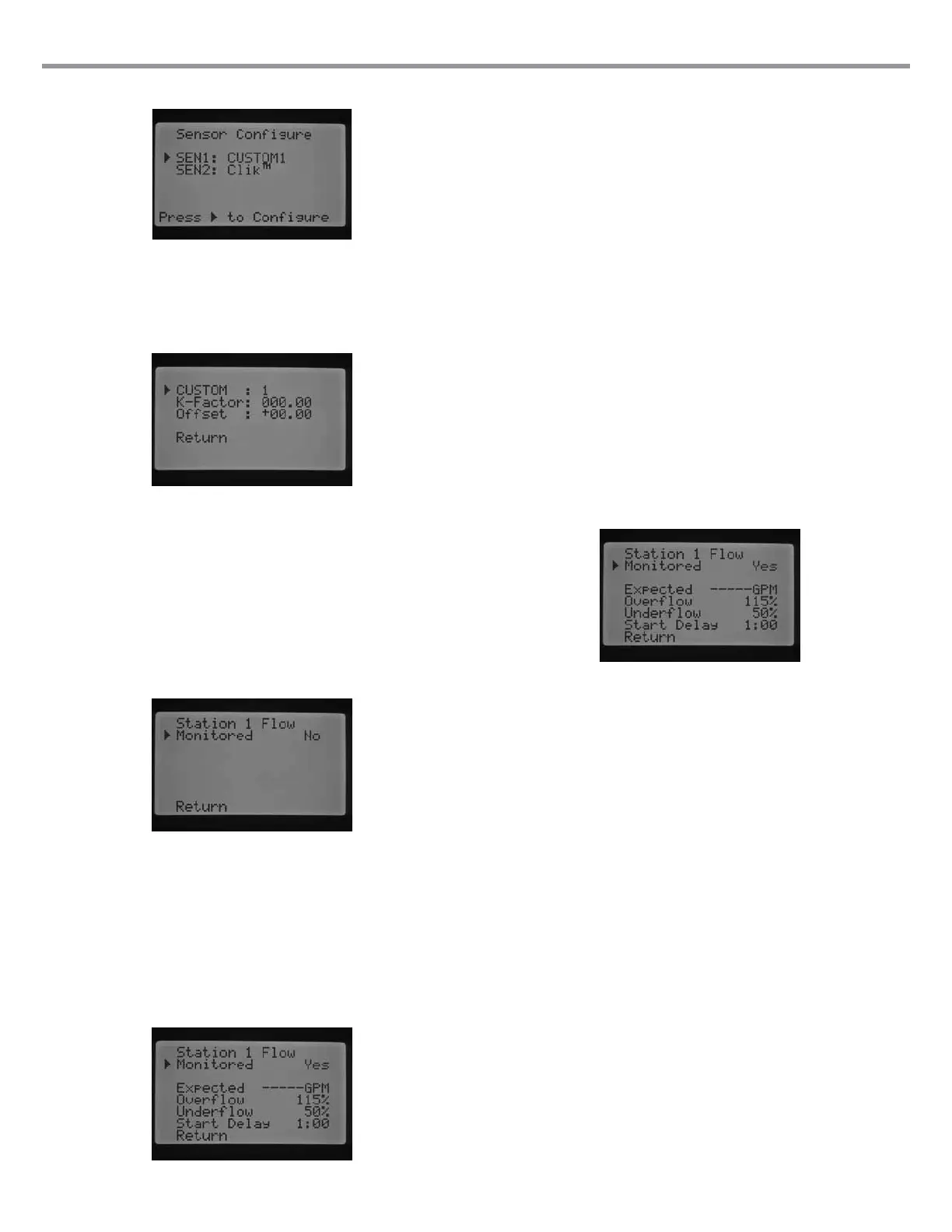

3. The cursor will be displayed next to Monitored. Use the + / – button

to enable or disable ow monitoring for that station.

If ow monitoring is enabled (Yes), you will be given the ability to change

certain characteristics of each stations monitored ow. As soon as the

station is enabled the new screen will appear with the following selections:

• Expected Flow – the amount of ow expected for that station in

Gallons Per Minute (GPM )or Liters Per Minute (LPM)

• Overow – Can be set from 110% to 300% of Expected Flow. During

system operation, if the station ow exceeds the Overow limit, the

controller will shut the system down and begin diagnostic testing. For

example, if the expected ow is 20 GPM and the overow is set to

115%, the actual ow would need to exceed 15% (3 gallons) of the

expected ow. Therefore, the station would need to exceed 23 GPM

before the controller would go into overow alarm.

• Underow – Can be set from 10% to 100% of Expected Flow. During

system operation, if the actual station ow falls below the Underow

limit, the controller will shut the system down. For example, if the

expected ow is 20 GPM and the underow is set to 50%, the actual

ow would need to underow by 50% (10 gallons) of the expected

ow. Therefore, the station would need to ow at a minimum of 10

GPM before the controller would go into an underow alarm.

• Start Delay – Can be set from 5 seconds to 10 minutes. The Start

Delay prevents premature system shutdown due to erratic ow within

the mainline by providing a delay before the system shutdown occurs.

It allows the system to stabilize prior to shutting the system down

during Overow and Underow conditions.

After the station has been enabled, press the ▼ button to select any of

the features mentioned above. With the ► cursor pointing to the ow

characteristic, press the + / – button to increase or decrease the value until

the desired number is reached.

If ow monitoring is enabled for a specic station, the factory preset

values will be displayed. The expected ow will be blank, because the

actual learning process has not taken place. The learning process will be

discussed in the Manual Operation, Learn Expected Flow section. Overow

will be 115%, underow will be 50%, and the preset Start Delay will be set

to 1 minute.

Flow Operation is necessary to program in order for the controller to know

which stations to monitor. Important additional steps that need to be taken

to complete the ow monitoring setup. A ow sensor needs to be assigned

in the Sensor Conguration screen, and the stations set to be monitored

need their ows to be learned. These steps are required in order for ow

monitoring to occur.

If a station has been enabled for ow monitoring, it is important to know

that the System Status Dashboard ow light will become active for that

station. If the other components to complete the ow monitoring process

have not been programmed, but the station’s ow has been enabled, the

System Status Flow light will light Green indicating a normal ow.

A detailed description of what happens in the case of an overow or

underow is discussed in the controller Diagnostics and Troubleshooting

section under System Status Dashboard, Flow. It is very important to read

and understand this description before ow monitoring occurs.

23

Loading...

Loading...