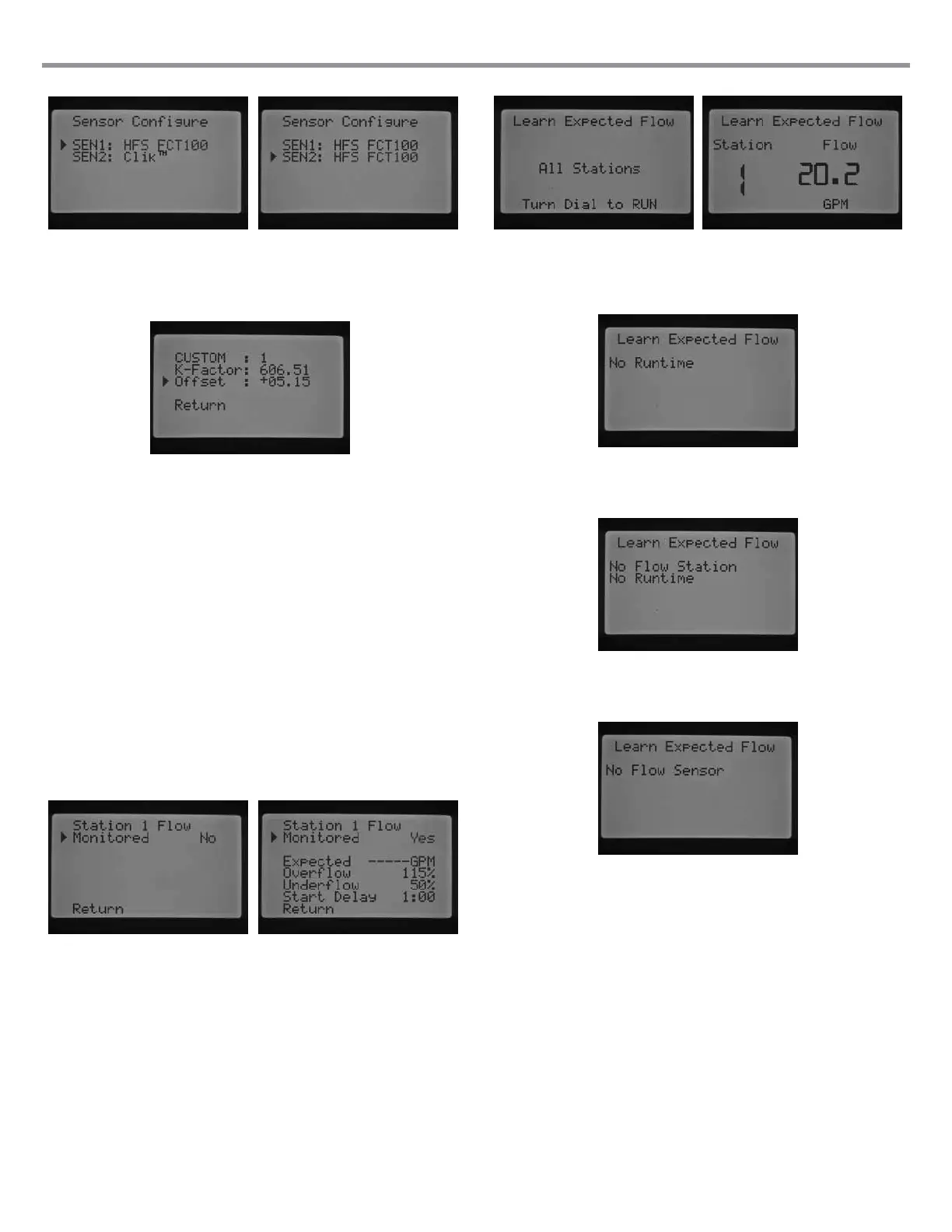

4. For non-Hunter ow sensors, Custom 1, Custom 2, or Custom 3 (Metal

Version I-Core) can be selected as a ow sensor type. With custom

selected, press the ► button to program the K-Factor and Offset that is

specic to that sensor, specied by the ow sensor manufacturer.

5. Use the ▲or ▼ buttons and the ◄ or ► buttons to navigate through

the Custom, K-Factor, and Offset screen. Once you navigate to a

particular number and it starts ashing, the number may be changed,

press the + / – button to either increase or decrease the value. Once

you have completed entering the K-Factor and Offset specied by

the manufacturer of the ow sensor, use the ▼ button to return to the

main Sensor Conguration screen.

6. Use the ◄ button to return to the Advanced Features main screen, or

move the dial from ADVANCED FEATURES and simply return the dial

back to Advanced Features. Use the ▼ button to move the ► cursor

next to Flow Operation, press the + button.

7. The display will show Station 1 Flow Monitored and a ashing NO.

A selection of NO will indicate that this station’s ow will NOT be

monitored. Press the + button, and the value will change to YES.

This selection will allow for this station’s ow to be monitored. If ow

monitoring is enabled (Yes), a new screen will appear with important

characteristics of each stations monitored ow. Use the ◄ or ►

buttons to scroll through the station numbers and assign YES or NO

for the stations ow monitoring.

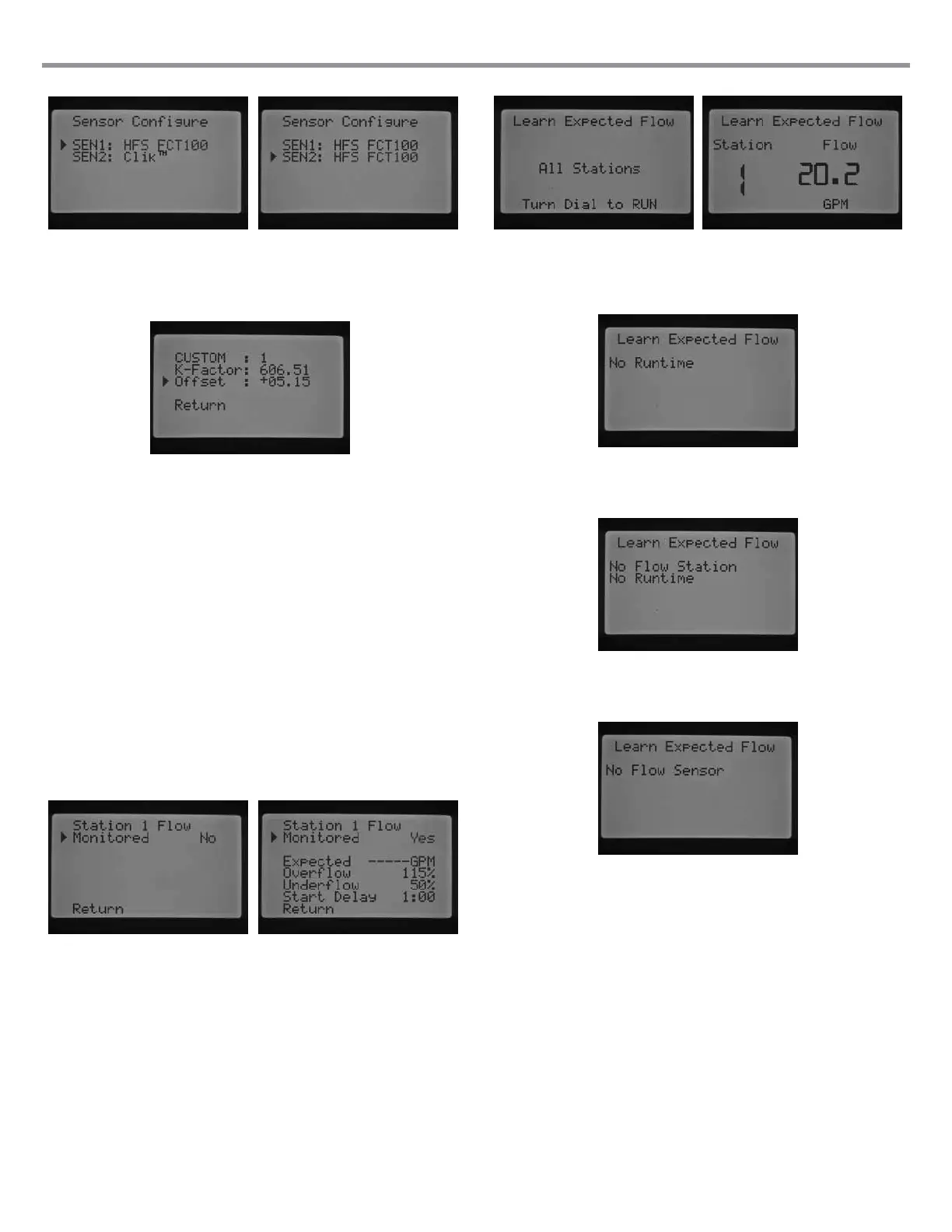

8. Turn the dial to MANUAL OPERATION. Use the ▼ button to move

the ► cursor next to Learn Expected Flow, press the + button.

9. If you would like to learn the ow for All Stations, simply turn the

dial to RUN. The controller will learn all the stations that have been

programmed for their ows to be monitored, and have programmed

run times. The learning process will actually activate each station

automatically, operating each station approximately one minute

to learn the ow rate. Once all the stations have been learned,

the controller will return to its automatic programming and ow

monitoring will be active.

The Learn Expected Flow display will also indicate if there is a problem with

any programming. If station run times were not programmed in the Set

Station Run Times screen, the controller will display No Runtime in the

Learn Expected Flow screen.

If no stations were set to have their ows monitored in the Flow Operation

section of Advanced Features, the controller will display No Flow Station as

well as No Runtime in the Learn Expected Flow screen.

If no HFS FCT size was programmed in the Sensor Conguration section of

Advanced Features, the controller will display No Flow Sensor in the Learn

Expected Flow screen.

Once ow monitoring has been established, the rules that apply to an

overow or underow condition are very important to understand. There

is a diagnostic testing procedure the controller will activate to determine

if there is an overow or underow condition. A complete description of

the process is explained in the Controller Diagnostics and Troubleshooting

section under System Status Dashboard, Flow. It is important to read this

section in order to understand the ow monitoring process.

HIDDEN FEATURES (CONTINUED)

30

Loading...

Loading...