Oil Levels

Check oil levels for each compressor and the

Turba-shed:

Compressor sight glass

1

⁄8 to

1

⁄2 full

Turba-shed between two lower sight glasses.

If oil level is low, add recommended oil only:

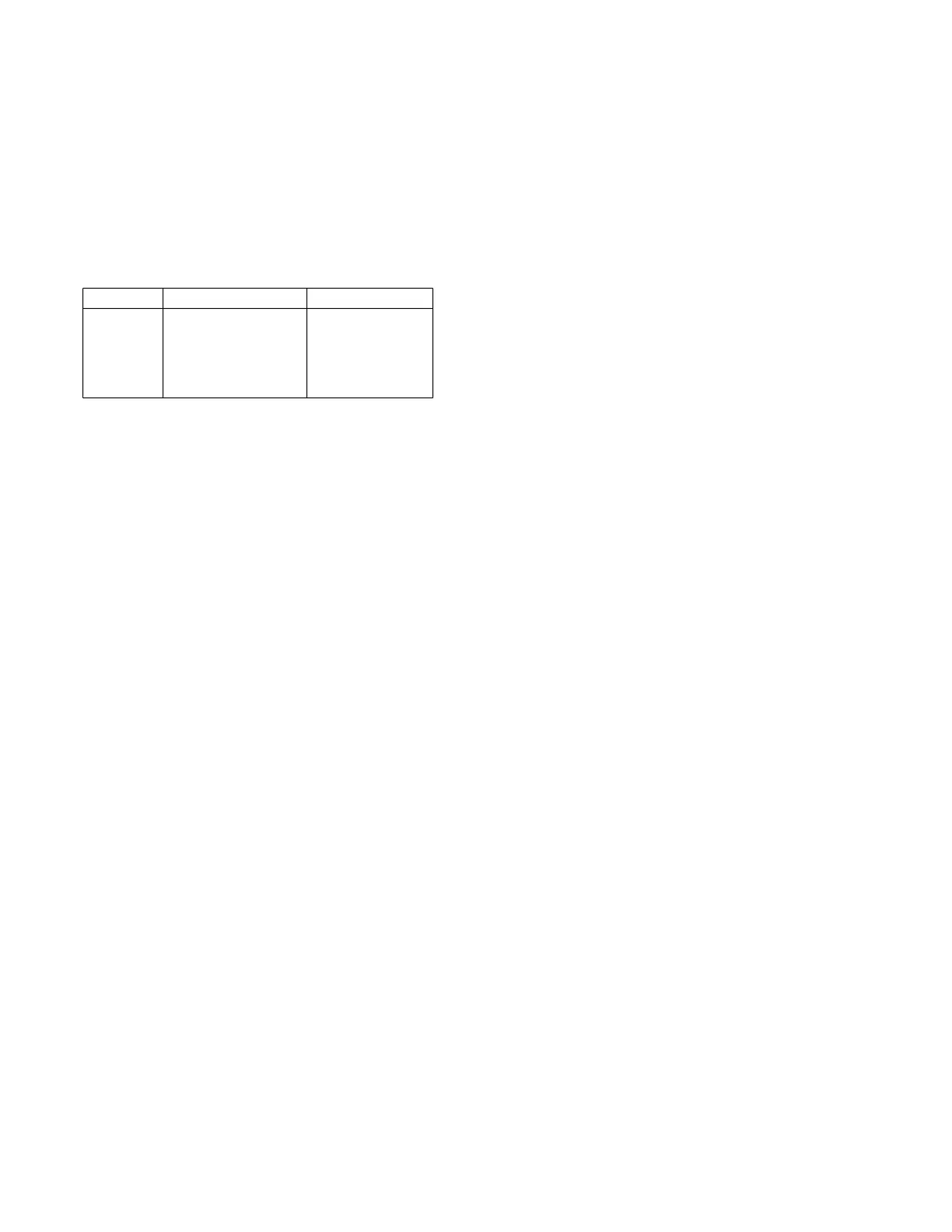

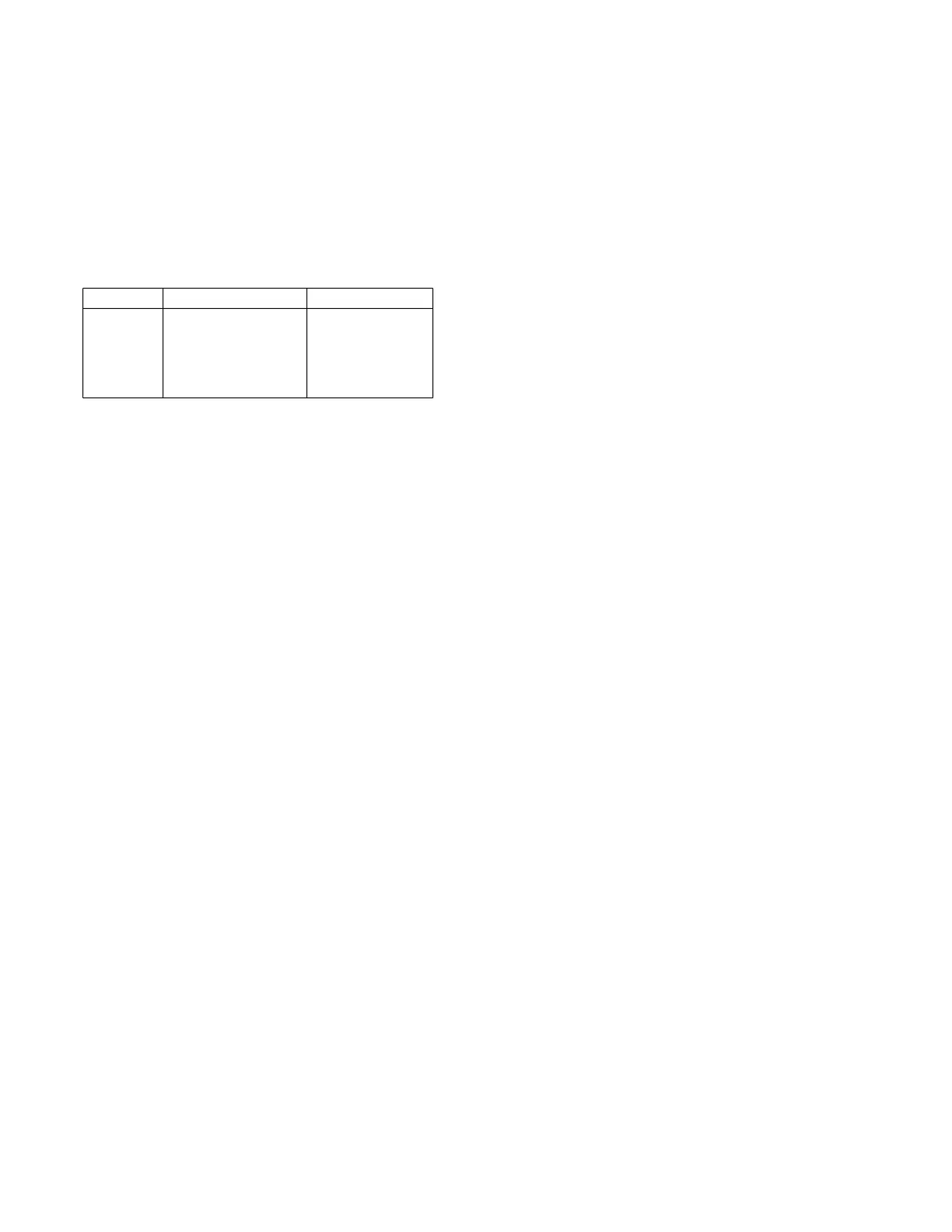

C o p e l a n d C a r l y l e

R 2 2 Suniso 3GS Suniso 3GS

R 4 0 4 A / Mobile EAL ICI Emkarate

R 5 0 7 A R C T I C 22 CC R L 6 8 H

E v a c u a t i o n

Nitrogen and moisture will remain in the

system unless proper evacuation procedures

are followed. Nitrogen left in the system may

cause head pressure problems. Moisture causes

T E V ice blockage, wax build up, acid oil, and

sludge formation.

Do not simply purge the system—this proce-

dure is expensive, harmful to the environment,

and may leave moisture and nitrogen behind.

Do not run the compressors to evacuate—this

procedure introduces moisture into the

compressor's crankcase oil and does not

produce adequate vacuum to remove mois-

ture from the rest of the system at normal

t e m p e r a t u r e s .

S e t u p

Using all copper lines and packless valves,

connect an eight CFM or larger vacuum pump

to a

7

⁄8-inch header and from the header to at

least three access ports on the rack. Connect

one micron vacuum gauge at the pump and

one at the furthest point in the system from

the rack. Plan procedures so breaking the vac-

uum with refrigerant will not introduce conta-

minates into the system. The vacuum pump

must be in good condition filled with fresh oil

to achieve desired results.

Procedure

Pull a vacuum to 1500 microns. If the vacuum

fails to hold, determine the cause and correct.

Begin again with the first of the three required

evacuations.

Break the vacuum with R22 vapor to a

pressure of about 2 psig. Do not exceed the

micron gauge transducer's maximum

pressure limit. Liquid refrigerant may cause

damage to components through thermal

shock or a pressure surge to the transducer of

the micron gauge.

Repeat first two steps.

Install the suction and liquid drier cores.

Pull a vacuum to 500 microns. Close vacuum

header valves and allow system to stand for a

minimum of 12 hours. If the 500 micron

vacuum holds, charging may begin. If the

500 micron vacuum does not hold, the cause

must be determined and corrected. Repeat the

entire evacuation procedure from the first

step.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 • Printed in USA

START-UP and MAINTENANCE Revised August 1, 1996

9 - 2

Loading...

Loading...