OVERVIEW

This section deals with the operation and

maintenance of the major valves which may

be found with the Super Plus™ System.

EPR VALVE

Evaporator Pressure Regulator Valves respond

to upstream pressure and are used to maintain

a minimum evaporator temperature. Remem-

ber two keys when dealing with rack mounted

EPRs. The first is the pressure drop from the

merchandiser to the machine room. The final

test for setting an EPR should always be evap-

orator discharge air temperature or product

temperature. The second is that low pressure

drop EPR Valves used on the Super Plus™

require an external high pressure supply to

power the main piston chamber. This high

pressure supply must maintain a

positive differential of at least 50 psig above

the down stream side of the valve. Lower

pressure differentials may cause valve

malfunction.

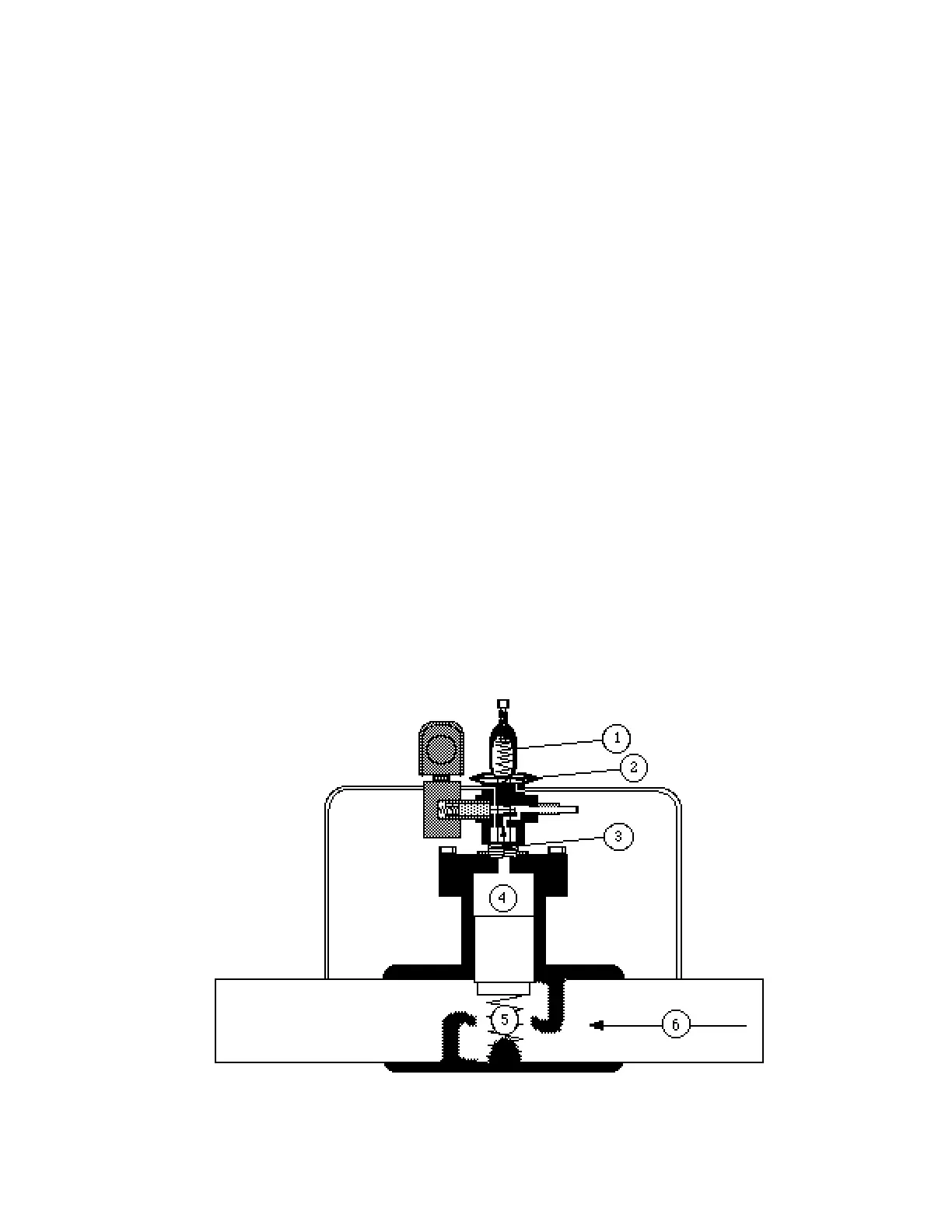

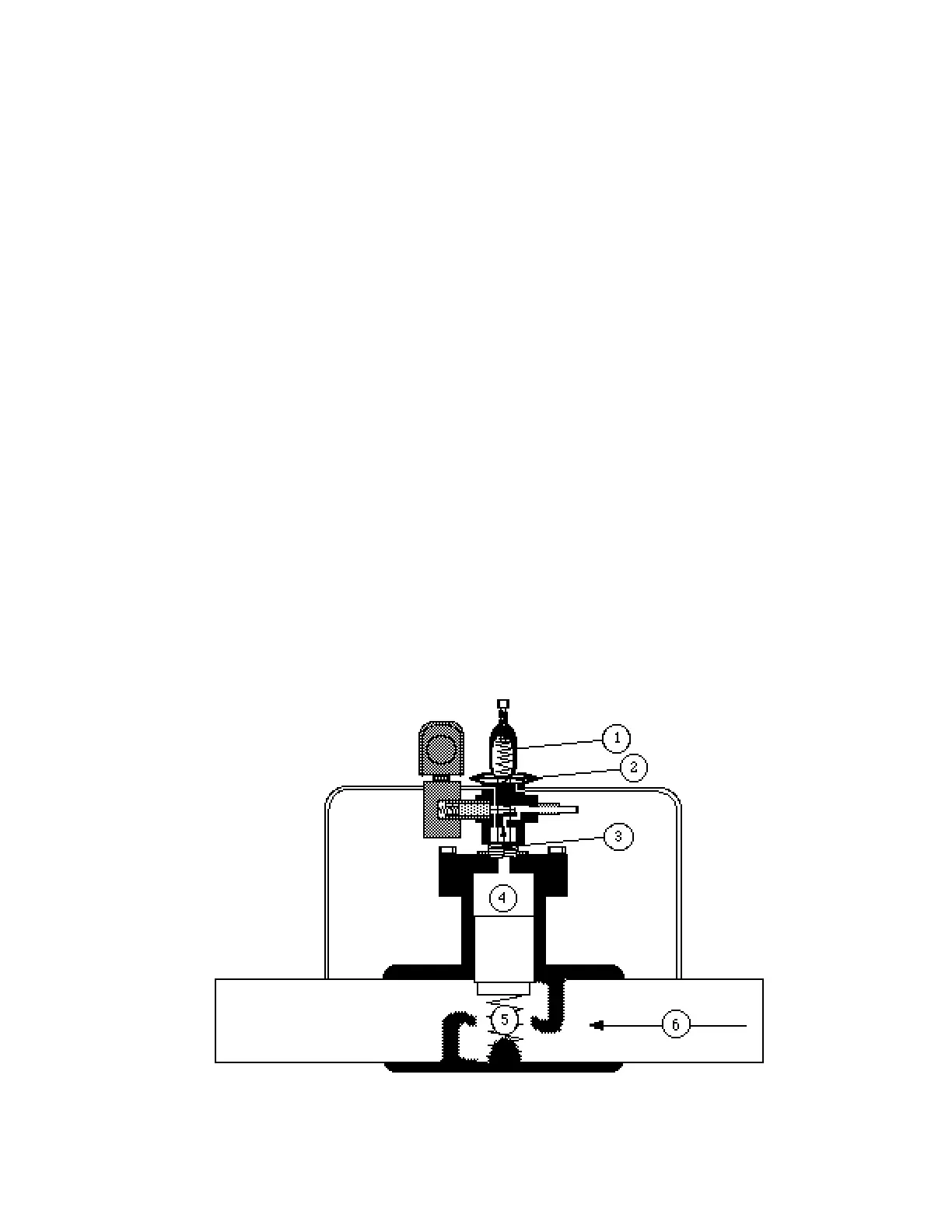

Basically all evaporator pressure regulator

valves open on upstream suction pressure rise.

Achieve the desired suction pressure by bal-

ancing Adjustment Spring ➀ a g a i n s t

Upstream Suction Pressure ➁ and Fixed

Pressure Counter Spring ➂. As upstream

pressure rises it closes the high pressure inlet

to the Main Valve Chamber ➃. The down-

stream bleed off reduces the Main Chamber

pressure to the point that piston spring ➄ and

Upstream Pressure ➅ open the main valve.

EPR Valves equipped with a Suction Stop

Solenoid are used with Koolgas Defrost.

When de-energized, this solenoid causes the

Main Valve to close completely.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 • Printed in USA

Revised August 1, 1996 P/N 340272A

7 - 1

CONTROL VALVES

Loading...

Loading...