OVERVIEW

This section deals with the information neces-

sary for installing the refrigeration lines for a

Super Plus™ refrigeration system. The Super

Plus™ components are piped as completely as

practical at the factory. Field piping requires

only interconnection of the major components

and to the refrigerators.

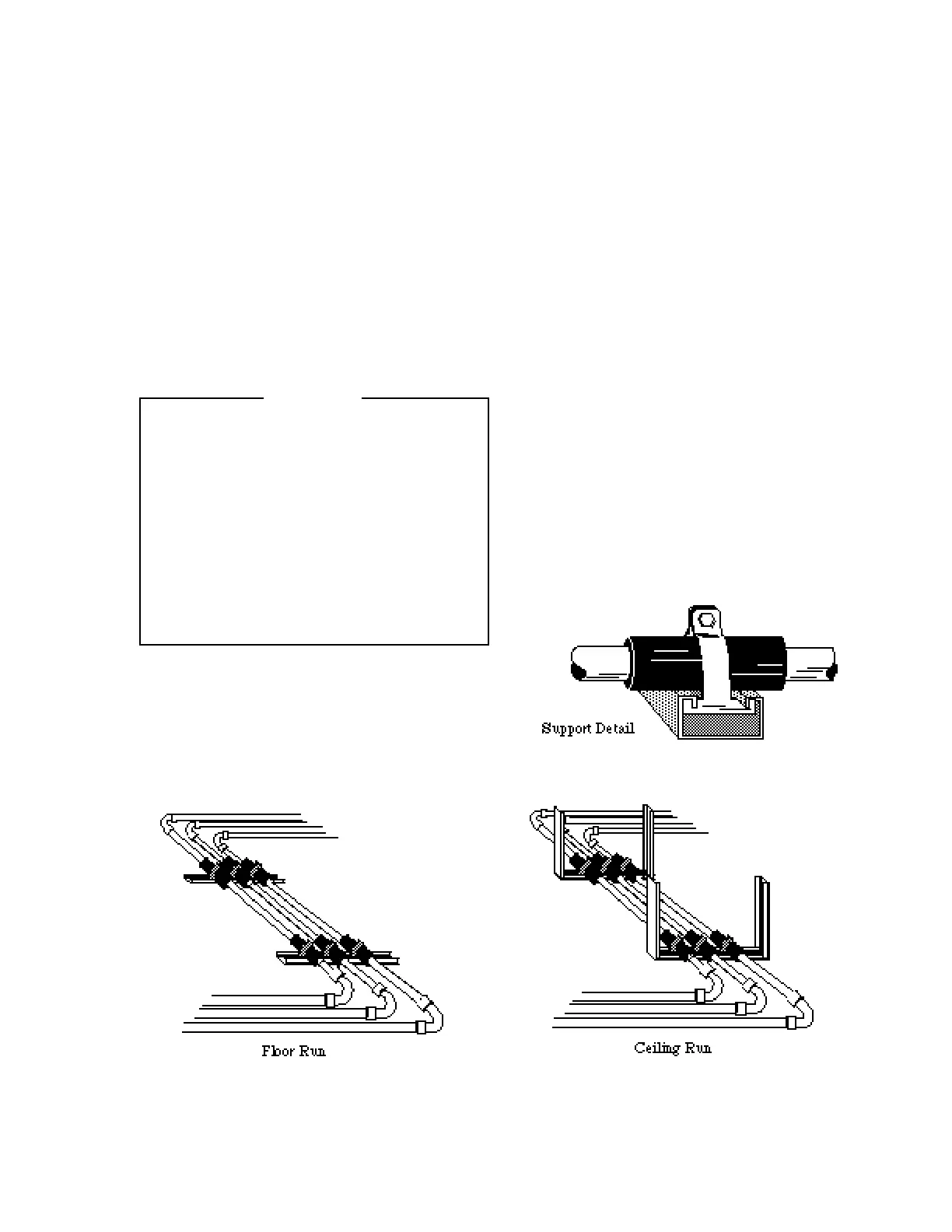

REFRIGERATION LINE RUNS

Liquid lines and suction lines must be free to

expand and contract independently of each

o t h e r. Do not clamp or solder them together.

Run supports must allow tubing to expand and

contract freely. Do not exceed 100 feet

without a change of direction or an off s e t .

Plan proper pitching, expansion allowance,

and P-traps at the base of all suction risers.

Use long radius elbows to reduce line resis-

tance and breakage. Avoid completely the use

of 45˚ elbows. Install service valves at several

locations for ease of maintenance and reduced

service costs. These valves must be UL

approved for 450 psig minimum working

pressure.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 • Printed in USA

Revised August 1, 1996 P/N 340272A

3 - 1

COMPONENT PIPING

Always use a Pressure Regulator

on nitrogen tanks.

Use only clean, dehydrated, sealed refriger-

ation grade copper tubing. Use dry nitrogen

in the tubing during brazing to prevent the

formation of copper oxide. All joints should

be made with silver alloy brazing material;

use 35% silver solder for dissimilar metals.

WARNING

Loading...

Loading...