MACHINE ROOM REQUIREMENTS

•The equipment room floor must solidly

support the compressor unit as a live load.

Ground level installation seldom presents

problems, but a mezzanine installation must

be carefully engineered.

• Ventilation should be 100 cfm per

compressor unit horsepower. The air inlet

should be sized for a maximum of 600 fpm

velocity. The ventilation fans should cycle by

thermostatic control.

•All machine room ventilation equipment

must be field supplied. Check local codes for

variances.

•Proper ventilation provides airflow across the

compressors. Duct work may be necessary.

•Provide a floor drain for disposal of

condensate that may form on the compressor

unit or header defrost assembly.

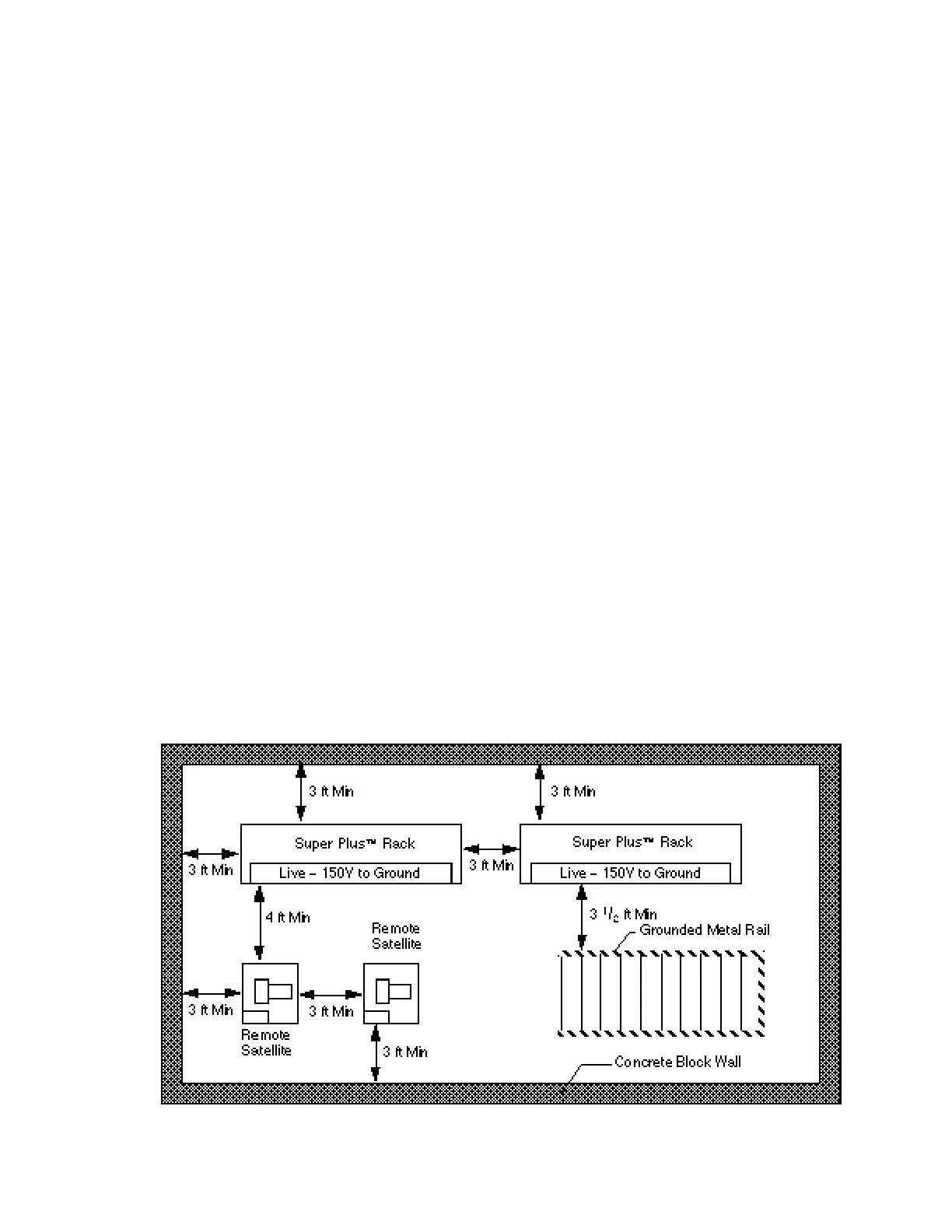

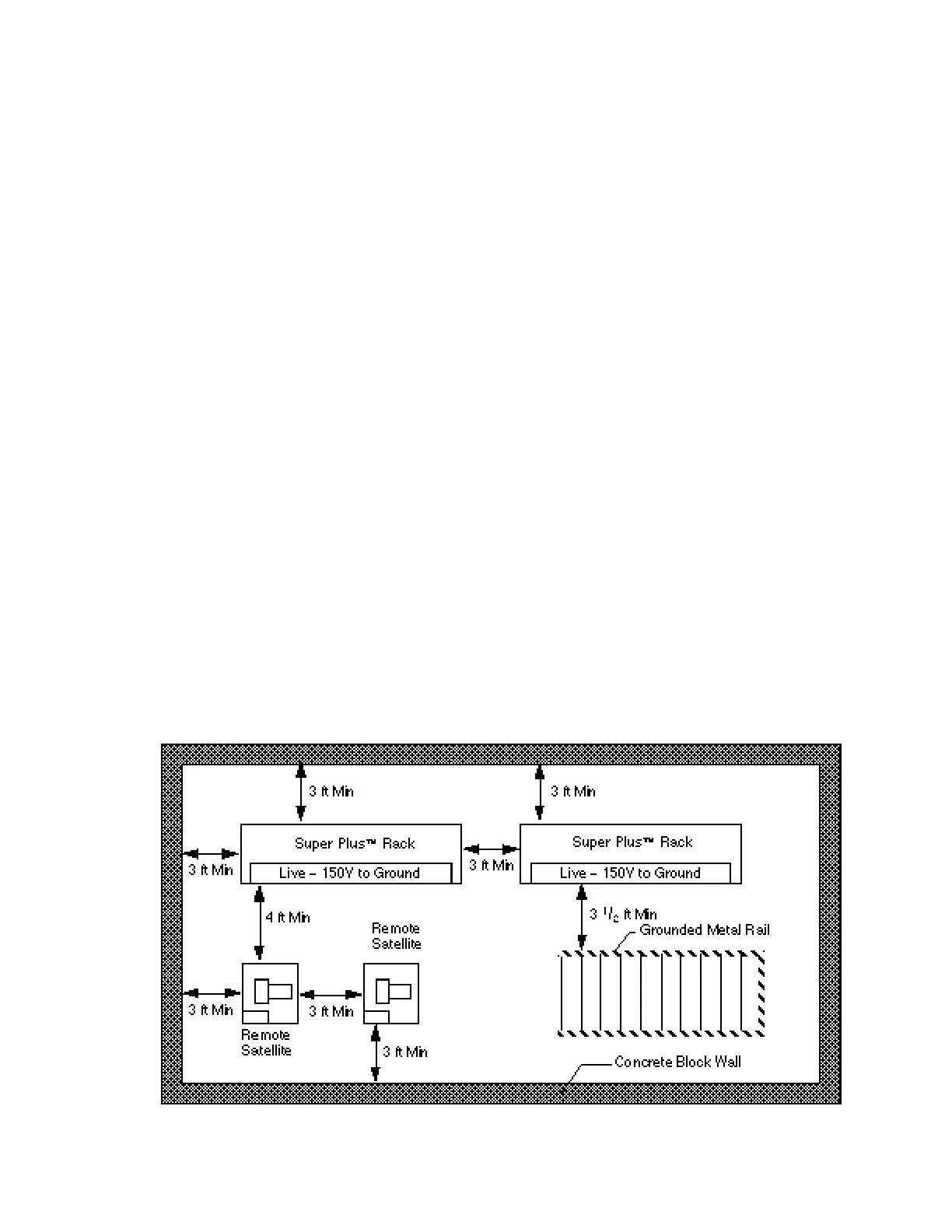

•Equipment must be located in the machine

room to provide enough working space for

service personnel, and to meet electrical codes.

•Consult NEC National Fire Handbook

particularly “Installation of Switch Boards”

and “Working Space Requirements”. The

figure below demonstrates some suggested

distances. Refer to local codes for each

installation.

Super Plus Load Points (Center to Center)

Rack Assembly Load Point Dimensions

Nomenclature Length Width

(in.) (in.)

01VK, 02VK, 04VY 51 30

03VK, 04VK, 05VY 64.5 30

05VK, 06VK, 06VY 87 30

07VK, 08VK, 07VY 109.5 30

08VY 66 & 66 30

N o t e : The 08VY and other Extended Rack

have three cross feet and six load points, not the

usual two and four. For nonstandard racks such

as with mechanical subcooling consult

Hussmann Engineering, Bridgeton, Mo.

Revised August 1, 1996 P/N 340272A

1 - 3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 • Printed in USA

Loading...

Loading...