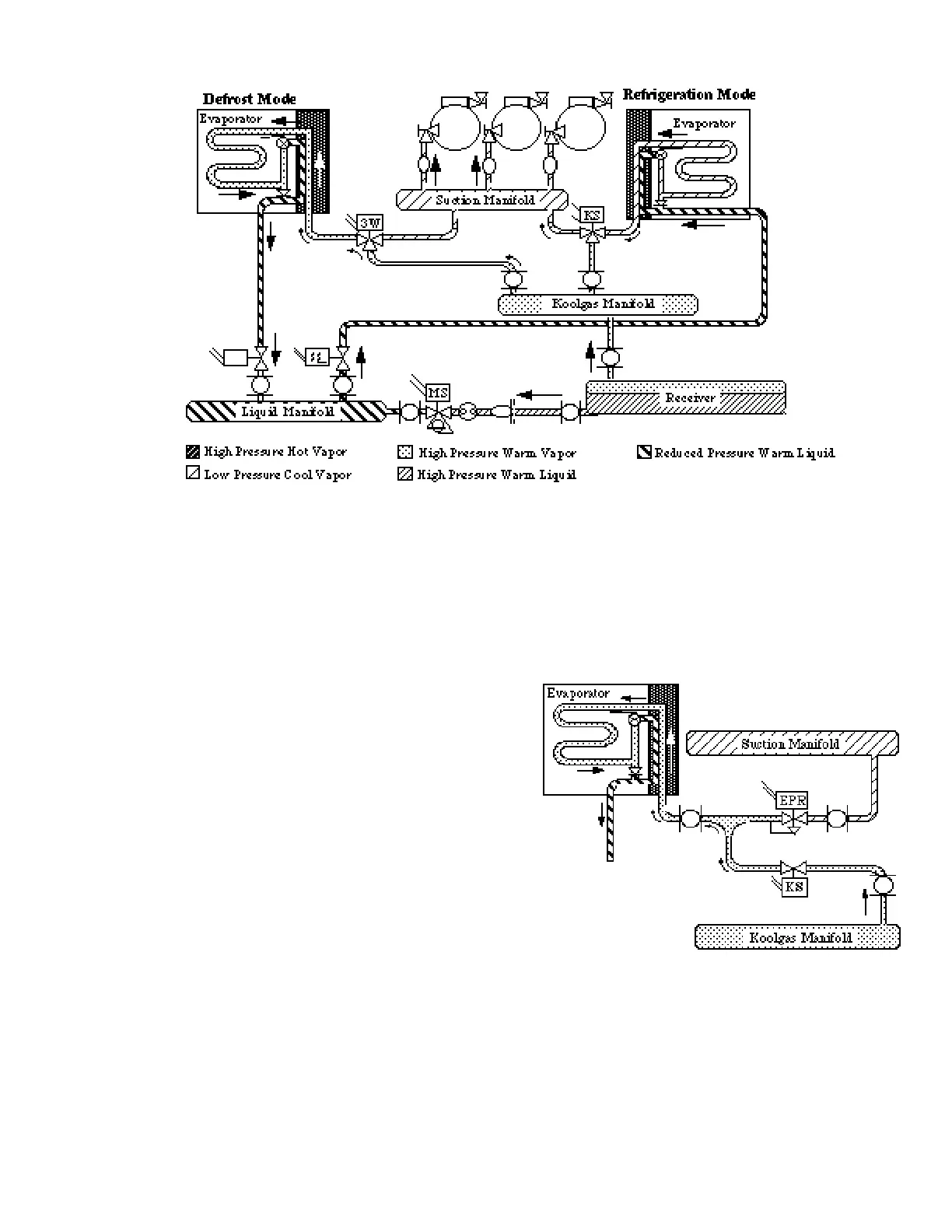

KOOLGAS DEFROST CYCLE

Beginning with the Receiver the Koolgas Cycle

splits in two directions—Receiver Vapor and

Receiver Liquid. The high pressure liquid

flowing from the Receiver is throttled by the

Main Liquid Line Solenoid Va l v e causing a

pressure reduction in the Liquid Manifold.

The Branch Liquid Line Solenoid Va l v e i s

designed to allow backflow into the reduced

pressure Liquid Manifold. When a branch of

refrigeration cases enters the defrost cycle its

Branch Va l v e allows refrigerant to flow into the

Liquid Manifold. The valve solenoid is energ i z e d

both for refrigeration and for defrost.

The Receiver Vapor flows directly into the

Koolgas Manifold. This Koolgas Va p o r

maintains the same high pressure as the

Receiver. A 3-Way Valve closes the suction line

to the Suction Manifold and opens the Koolgas

line to the E v a p o r a t o r. Koolgas Vapor flows

backward through the Evaporator, giving up

heat to the Evaporator for defrost.

The Koolgas Vapor condenses and flows into the

reduced pressure liquid line through a B y p a s s

Check Va l v e around the TEV. From there it is

returned to the Liquid Line Manifold.

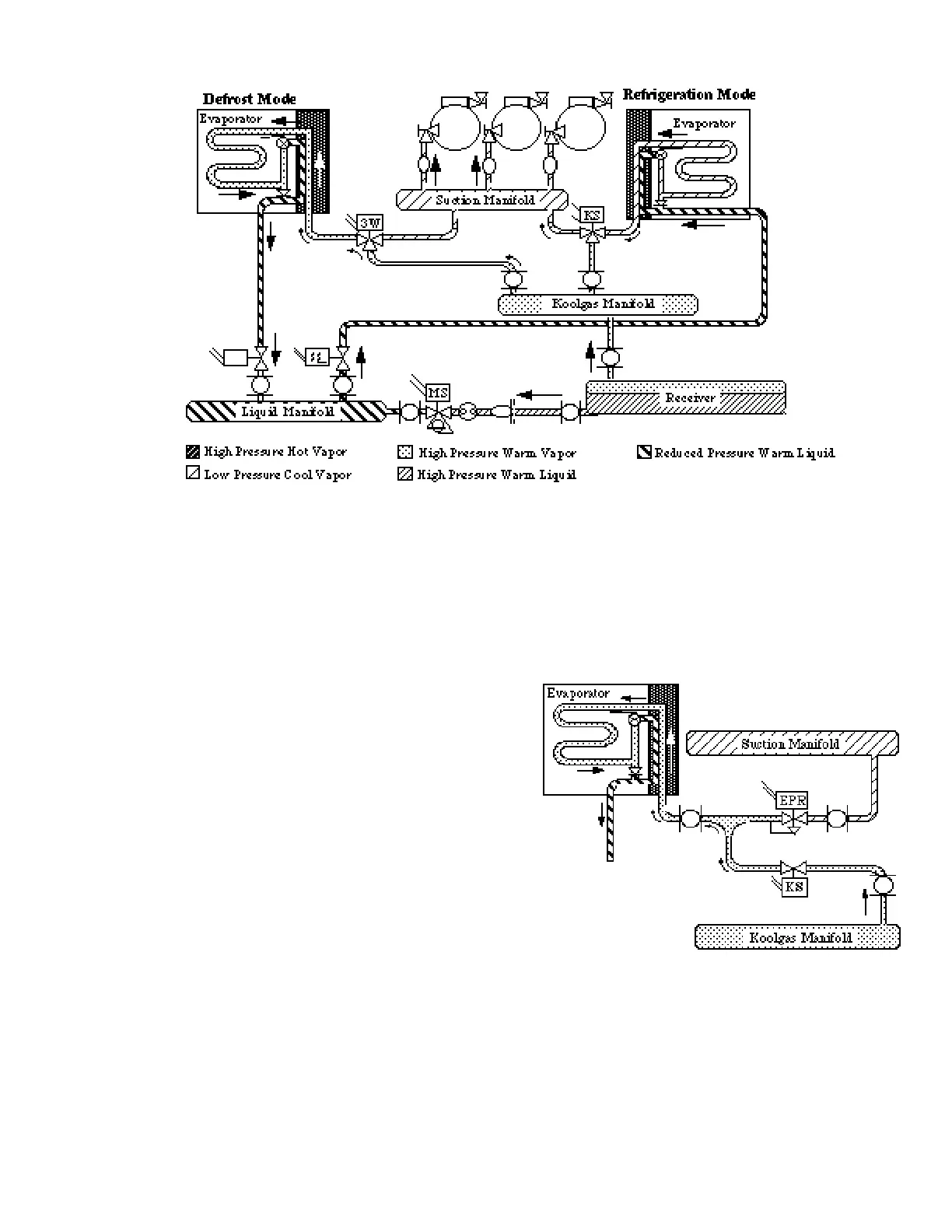

If a Suction Stop EPR Valve is used to control

Evaporator temperature, the 3-Way Valve is not

used. When defrost is called for, the suction line

control valve closes and a two-way K o o l g a s

Valve opens the line from the Koolgas Manifold

to the Evaporator.

Revised August 1, 1996 P/N 340272A

2 - 7

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 • Printed in USA

Loading...

Loading...