Troubleshooting the TEV

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 • Printed in USA

CONTROL VALVES Revised August 1, 1996

7 - 8

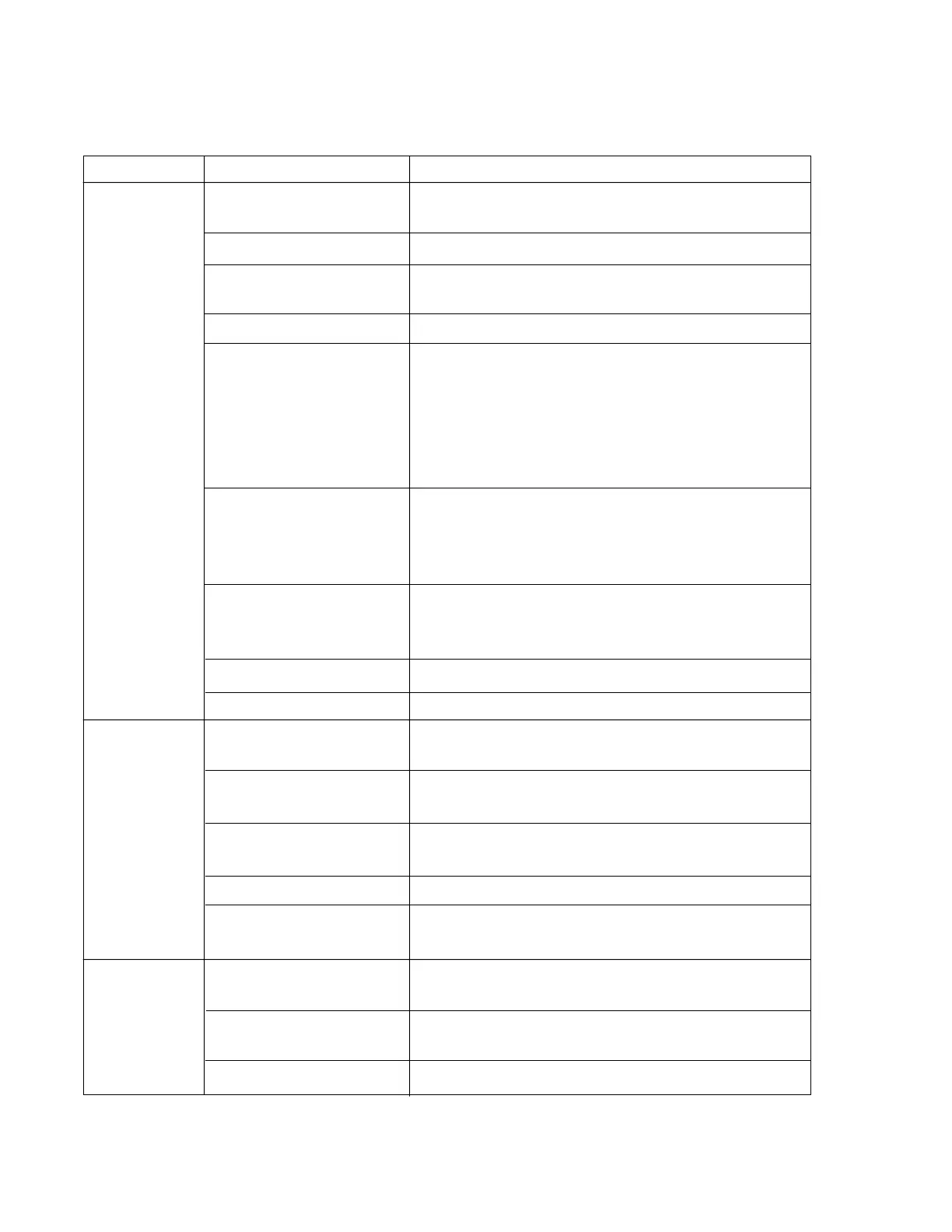

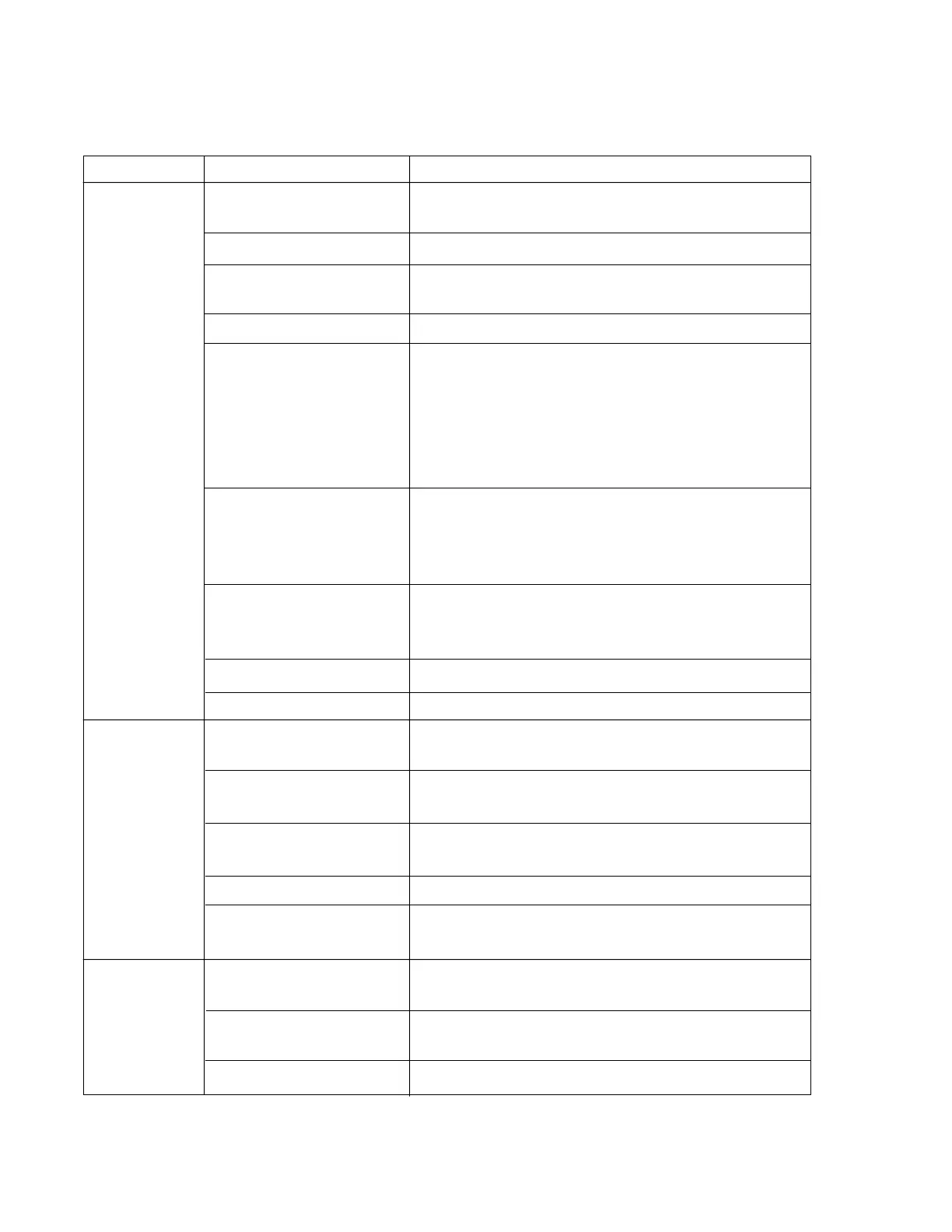

Malfunction Cause Action

Evaporator Superheat adjusted Adjust to proper superheat

Starved too high

Moisture Dehydrate and install new liquid line filter dryer

Dirt plugging strainer Remove and clean or replace

or valve mechanism

Wax Clean valve and install wax trapping dryer

Equalizer

Internal misapplied Install externally equalized TEV

External plugged Clear

Capped Install properly

Restricted Correct or repipe

Incorrect location Repipe

Flash gas upstream Head pressure too low, raise head pressure

of TEV Liquid supply line not exiting branch line from

bottom, repipe

Liquid supply line too small, repipe

Insufficient pressure Raise head pressure

drop across valve Install valve with adequate capacity at reduced

pressure

“Dead” Bulb Replace

Undersized TEV Install correct size

Evaporator Superheat adjusted Adjust to proper superheat

Flooded too low

Bulb not getting Check bulb and correct for good contact, location,

good thermal pickup and ambient influence

Moisture or dirt Clean and dehydrate and install new liquid line

holding valve open filter dryer

Oversized TEV Install correct size

Valve damage or Repair or replace

valve seat leak

Poor Uneven circuit load on Balance load (lightly loaded evaporator is

Performance multiple evaporators controlling TEV, starving loaded evaporator.)

Moisture or Dirt Clean and dehydrate and install new liquid line

filter dryer

TEV mis-sized Install correct size

Loading...

Loading...