Vacuum Blower System: 8-4

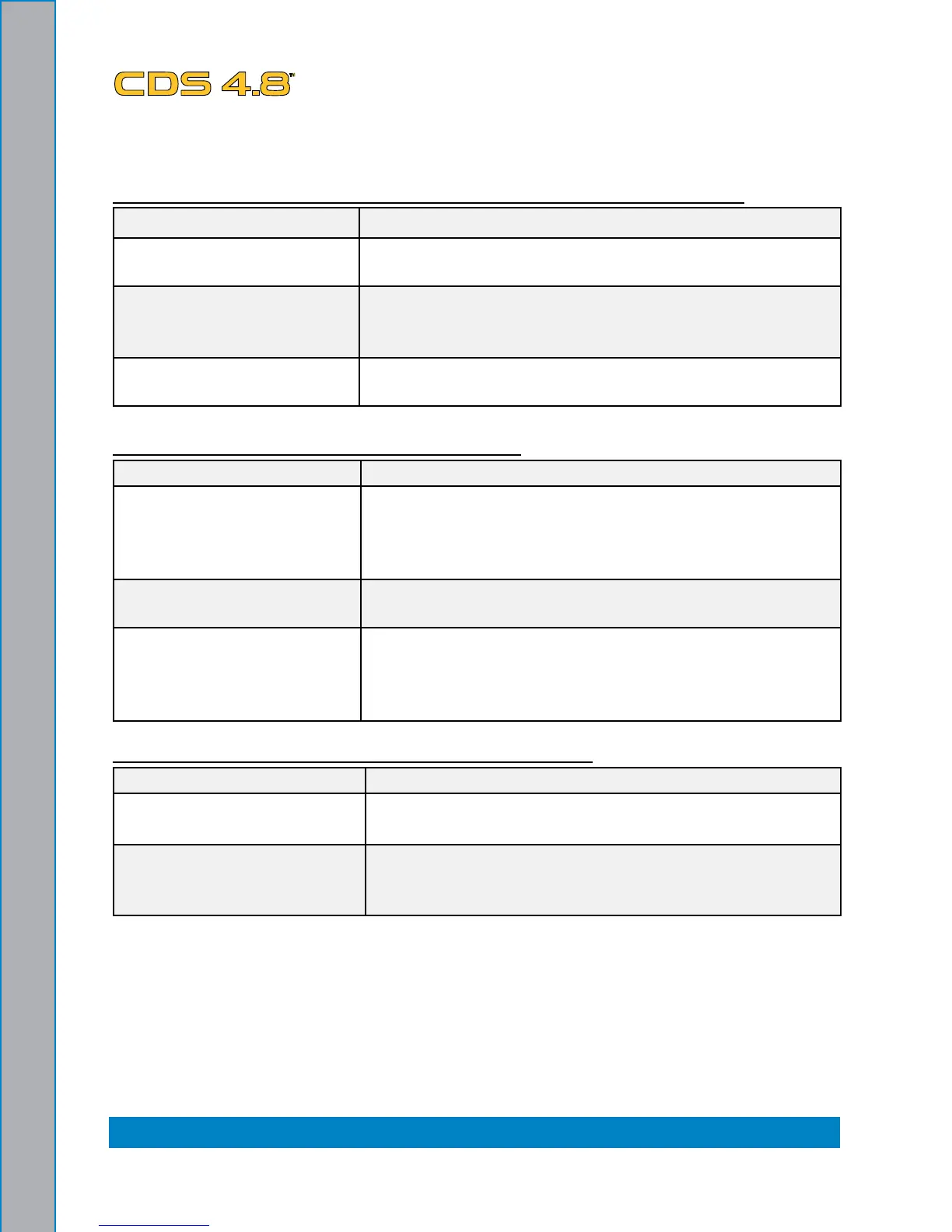

VACUUM BLOWER TROUBLESHOOTING

1.0. Weak vacuum at tool/wand. Gauge reads normal (10” Hg to 14” Hg)

POSSIBLE CAUSE SOLUTION

1.1. Clogged hoses or tool/

wand tube.

Disconnect hoses and carefully check for an obstruction.

1.2. Excessive length

of hoses connected to

machine.

Make sure machine is rated for the conditions under

which it is being operated.

1.3. Clogged heat

exchanger restricts vacuum.

See qualied service technician.

2.0. Vacuum gauge will not come up to 14” Hg

POSSIBLE CAUSE SOLUTION

2.1. There is an air leak

somewhere in the vacuum

system.

Check vacuum relief valve for proper adjustment. Check

all hoses for cuts and breaks. Check recovery tank lid

gasket. Make sure the recovery tank drain valve is fully

closed.

2.2. The vacuum gauge is

defective.

Test and replace as necessary.

2.3.Vacuum blower is

turning too slowly.

Check blower rpm at tachometer on the CDS’ dash.

Blower rpm should be 2 times the tachometer rpm. See the

throttle control kit instructions for further troubleshooting

assistance.

3.0. Vacuum gauge reads high with no hoses attached

POSSIBLE CAUSE SOLUTION

3.1. Filter in recovery tank is

clogged.

Remove and clean or replace as necessary.

3.2. Hose from recovery

tank to blower is collapsed

internally

Inspect and replace as necessary.

Loading...

Loading...