Machine Maintenance: 10-8

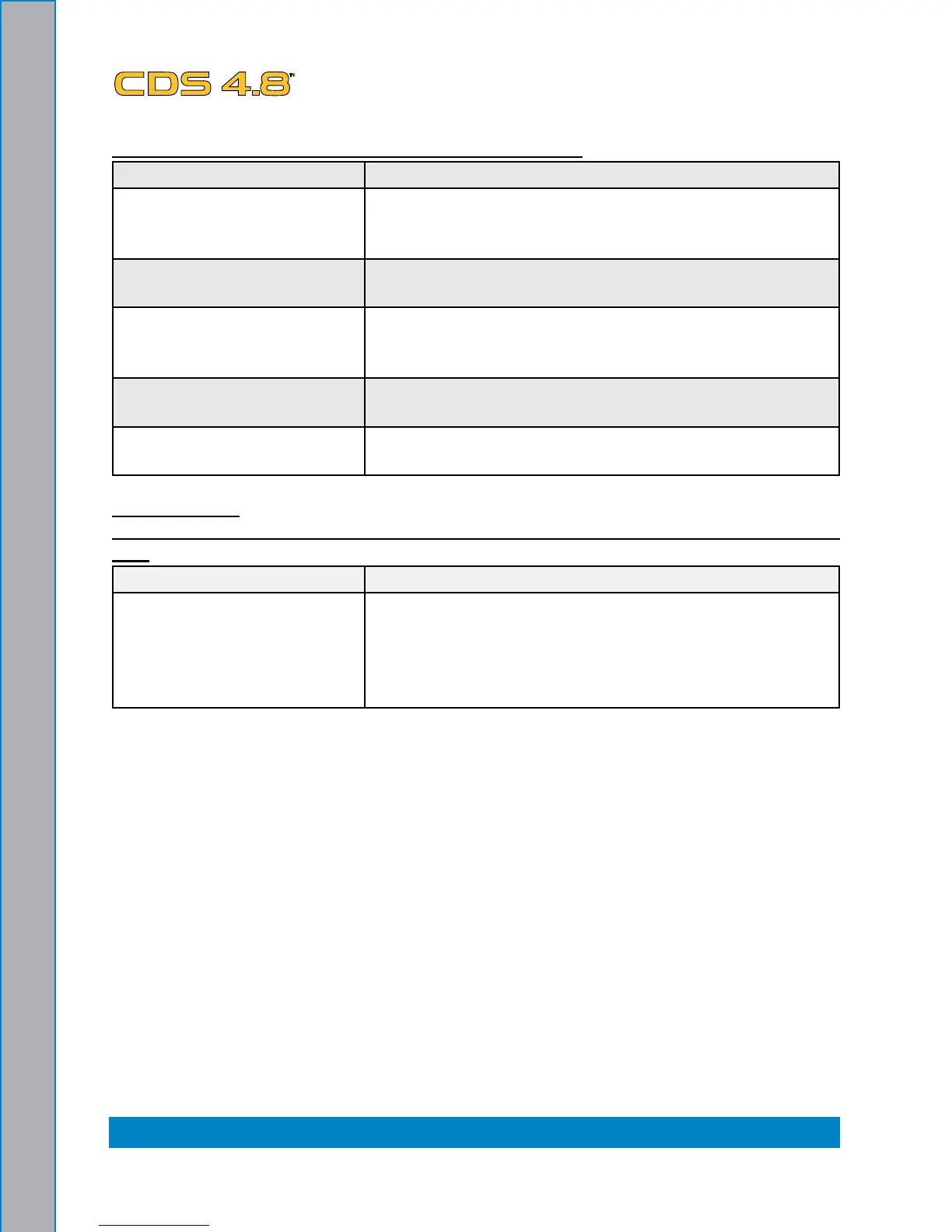

4.0. System attains normal heat but drops o sharply

POSSIBLE CAUSE SOLUTION

4.1. Solution ow at cleaning

tool is too high. Orice in tool

is too large or worn out.

Test ow of tool. Repair or replace as necessary.

4.2. The rpm of machine is

set too low.

Adjust as necessary.

4.3. Recirculation orice

plugged, giving incorrect

reading at gauge.

Clean lter screen and inspect orice. Clean or replace

as necessary.

4.4. Cleaning solution

pressure is too high.

Adjust pressure to normal. Inspect pressure gauge for

accurate reading.

4.5. Hard water deposits are

in the system.

Descale system as directed in this Owner’s Manual

(see page 10-4).

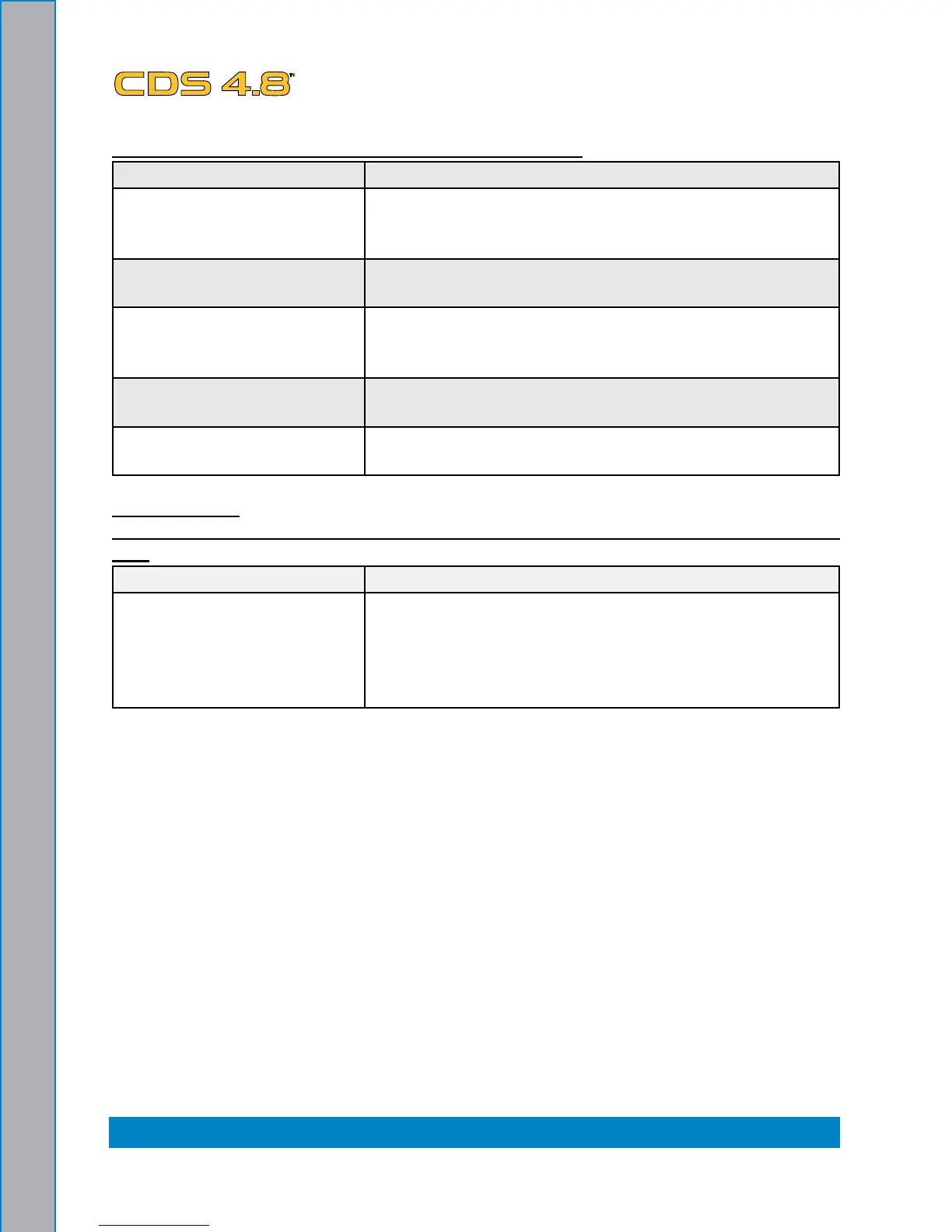

Miscellaneous

1.0. Vehicle radiator overows into coolant overow container while machine is in

use.

POSSIBLE CAUSE SOLUTION

1.1. Internal leak in coolant

heat exchanger.

Pressure test each heat exchanger separately to

determine which heat exchanger is faulty. This process

requires heated water and high pressure to simulate

the same conditions that are causing the leak. Refer to

qualied service technician if necessary.

Loading...

Loading...