TROUBLESHOOTING AND SYSTEM TESTS

powermax

65/85

Service Manual 5-37

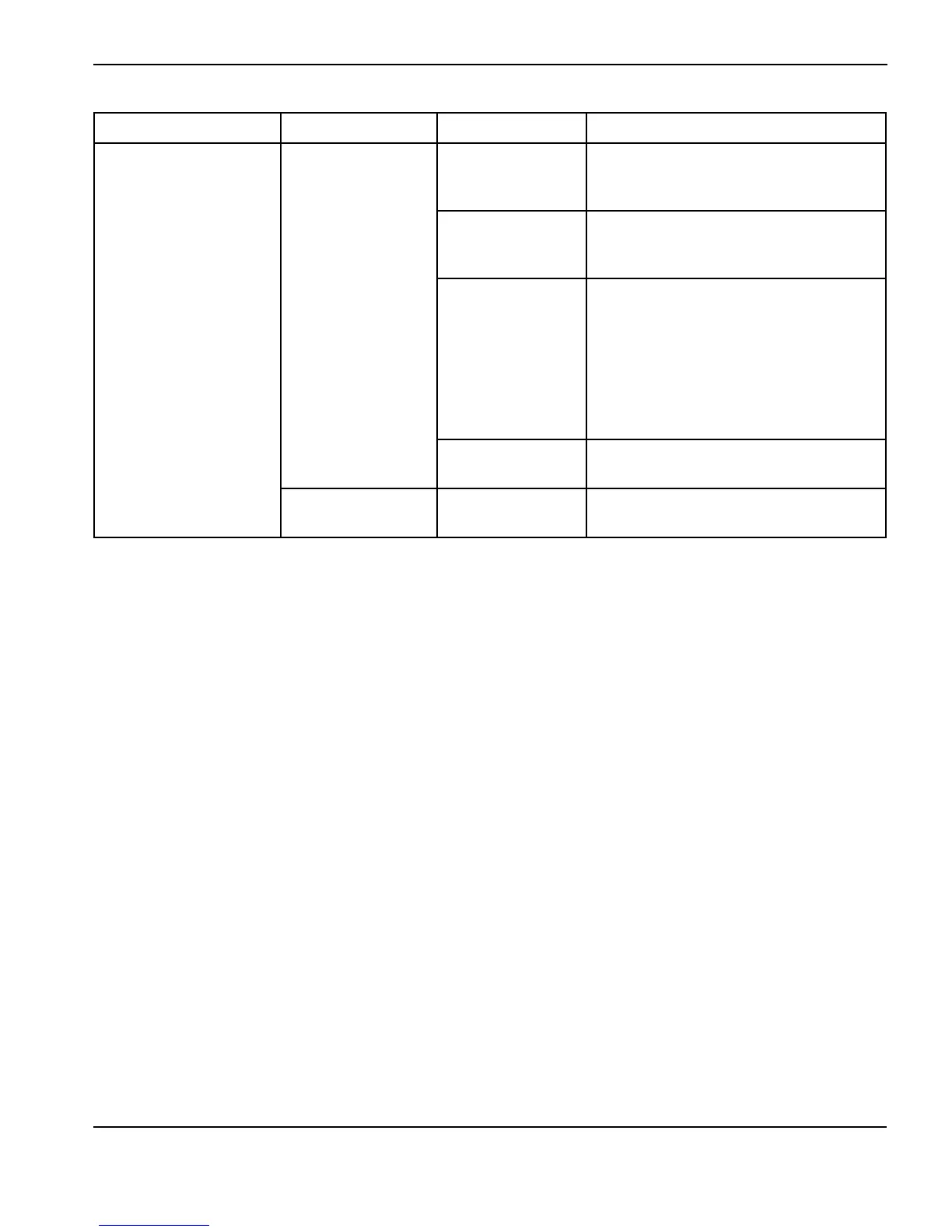

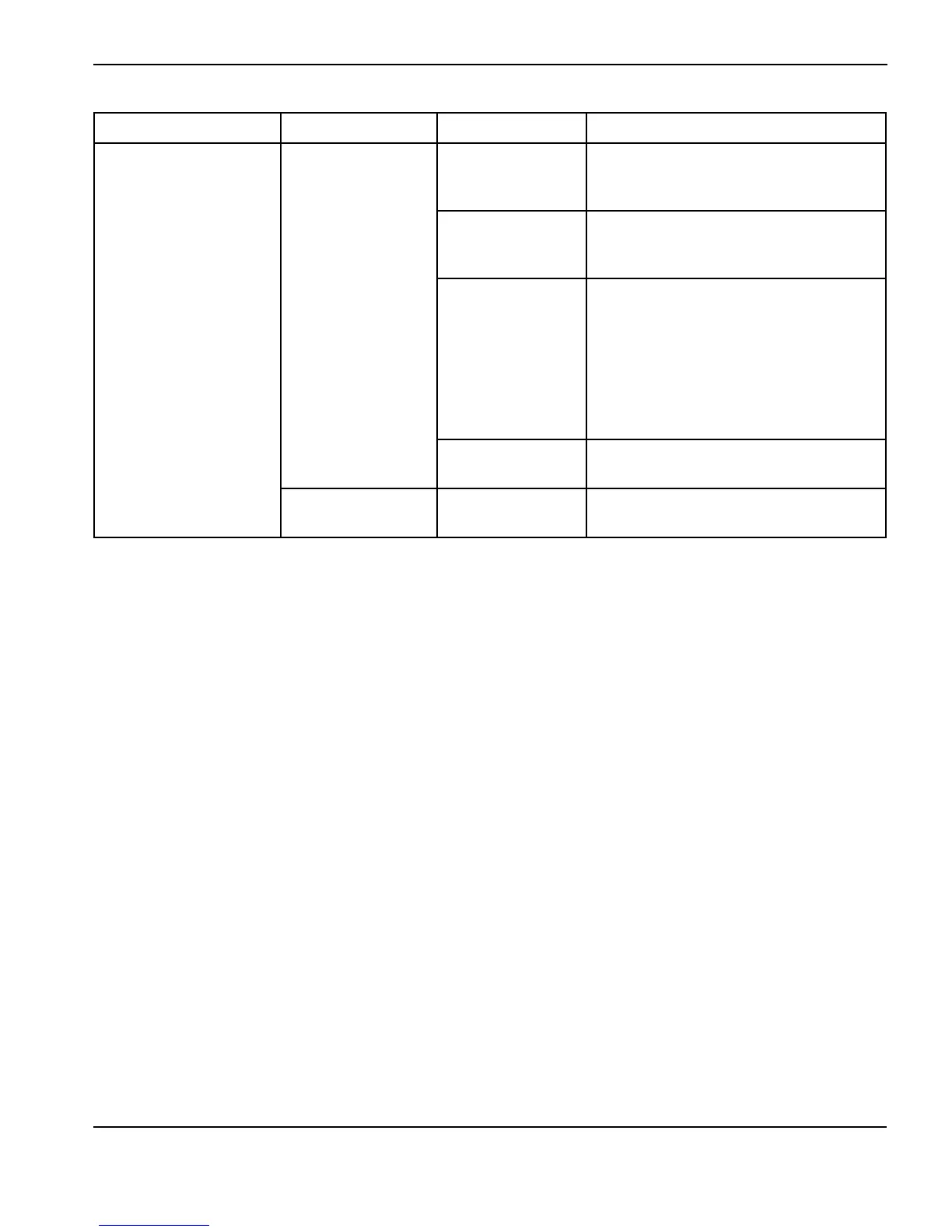

Problem Meaning Causes Solution

Machine does not cut

well (does not appear to

be cutting at full cutting

power) and the arc does

not time out after 5

seconds.

Inadequate ground.

• Poor work lead

connection.

• Verify that the work lead is attached to

the workpiece and the workpiece is free

of rust, paint, or other coatings.

• Damaged work

lead.

• Check the resistance across the work

lead. If the resistance is greater than 3

Ω, repair or replace the work lead.

• Faulty pilot arc

IGBT.

• Turn the power OFF, remove the

consumables, and check the resistance

between the plunger and the work

piece. If the resistance is less than 5

kΩ, check the resistance across the

pilot arc IGBT (two screws on 08). If the

resistance is less than 5 kΩ, replace the

pilot arc IGBT.

• Faulty control

board.

• Replace the control board.

Low output from the

power supply.

• Current is set too

low.

• Increase the current as needed.

Loading...

Loading...