POWER SUPPLY SETUP

2-14 powermax

65/85

Service Manual

Prepare the gas supply

The gas supply can be shop-compressed or cylinder-compressed. A high-pressure regulator must be used on either

type of supply and must be capable of delivering gas to the air inlet on the power supply.

If the supply quality is poor, cut speeds decrease, cut quality deteriorates, cutting thickness capability decreases, and

the life of the consumables shortens. For optimal performance, the gas should be compliant with ISO8573-1:2010,

Class 1.2.2 (that is, it should have a maximum number of solid particulate per m

3

of <20,000 for particle sizes in the

range of 0.1-0.5 microns, <400 for particle sizes in the range of 0.5-1 microns, and <10 for particle sizes in the range

of 1-5 microns). The maximum water vapor dew point should be <-40° C (-40° F). The maximum oil (aerosol, liquid, and

vapor) content should be less than 0.1 mg/m3.

Additional gas filtration

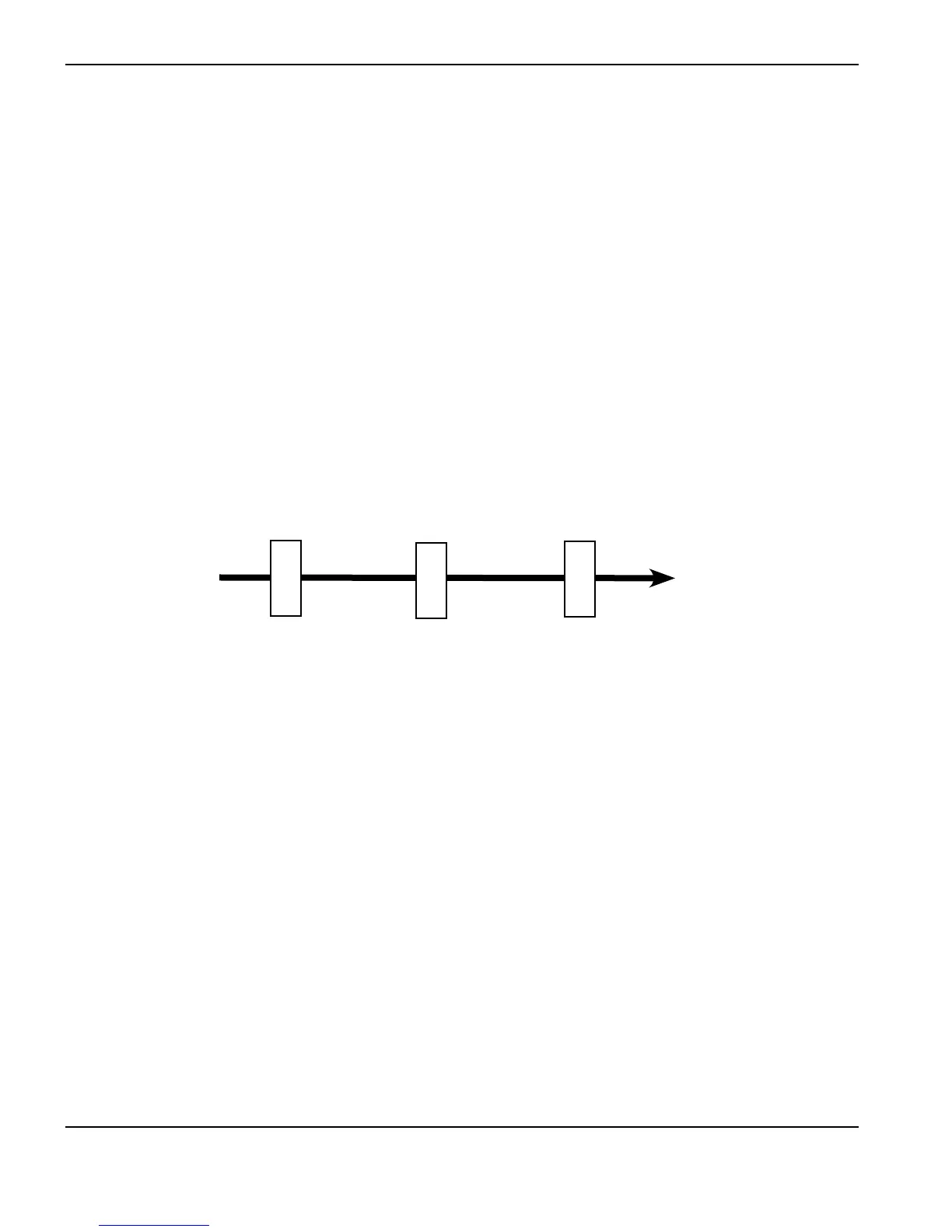

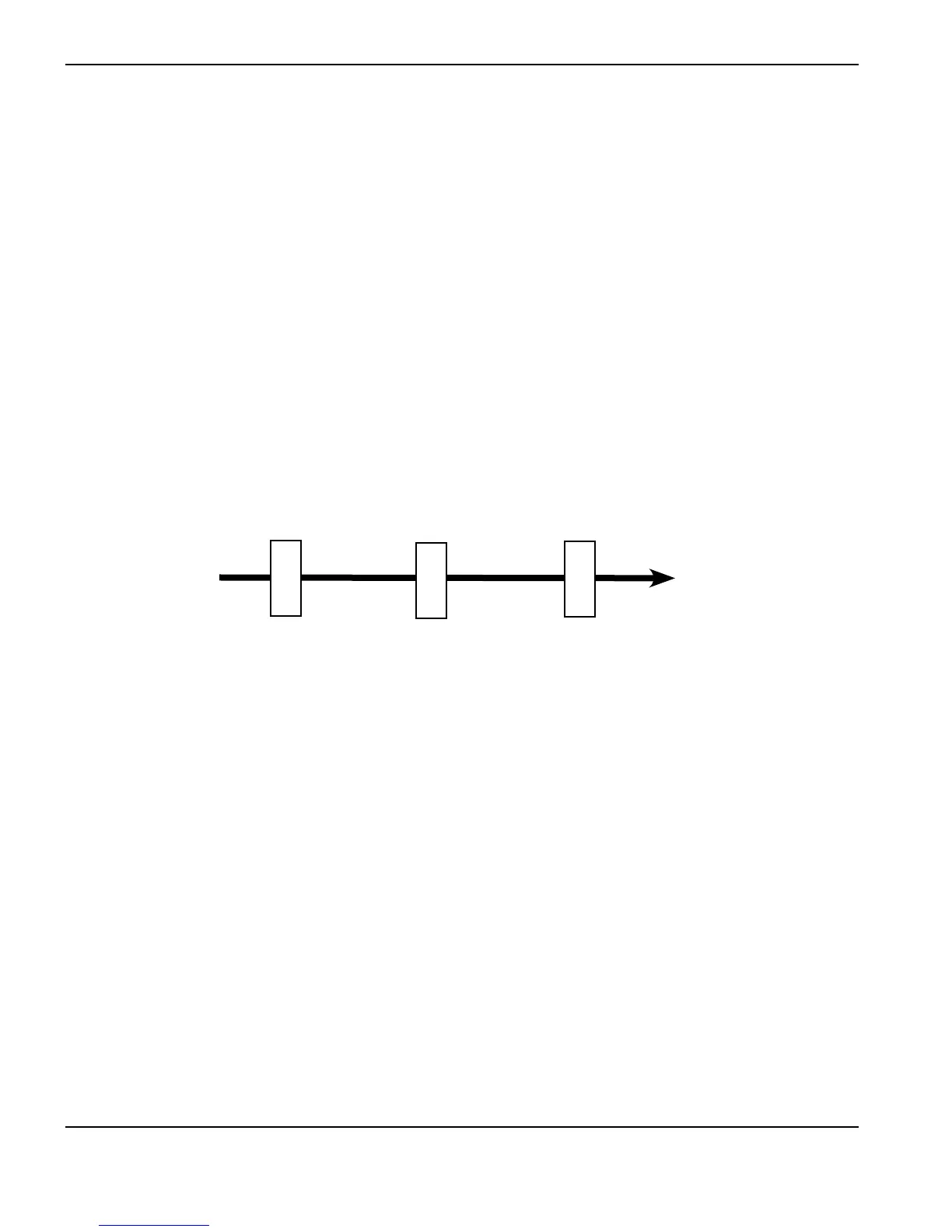

When site conditions introduce moisture, oil, or other contaminants into the gas line, use a 3-stage coalescing filtration

system, such as the Eliminizer filter kit (part number 128647) available from Hypertherm distributors. A 3-stage filtering

system works as shown below toclean contaminants from the gas supply.

Gas supply

Powermax65

Powermax85

Water and particle filter

Oil filter Oil vapor filter

The filtering system should be installed between the gas supply and the power supply. Additional gas filtration may

increase the required minimum inlet pressure.

Loading...

Loading...