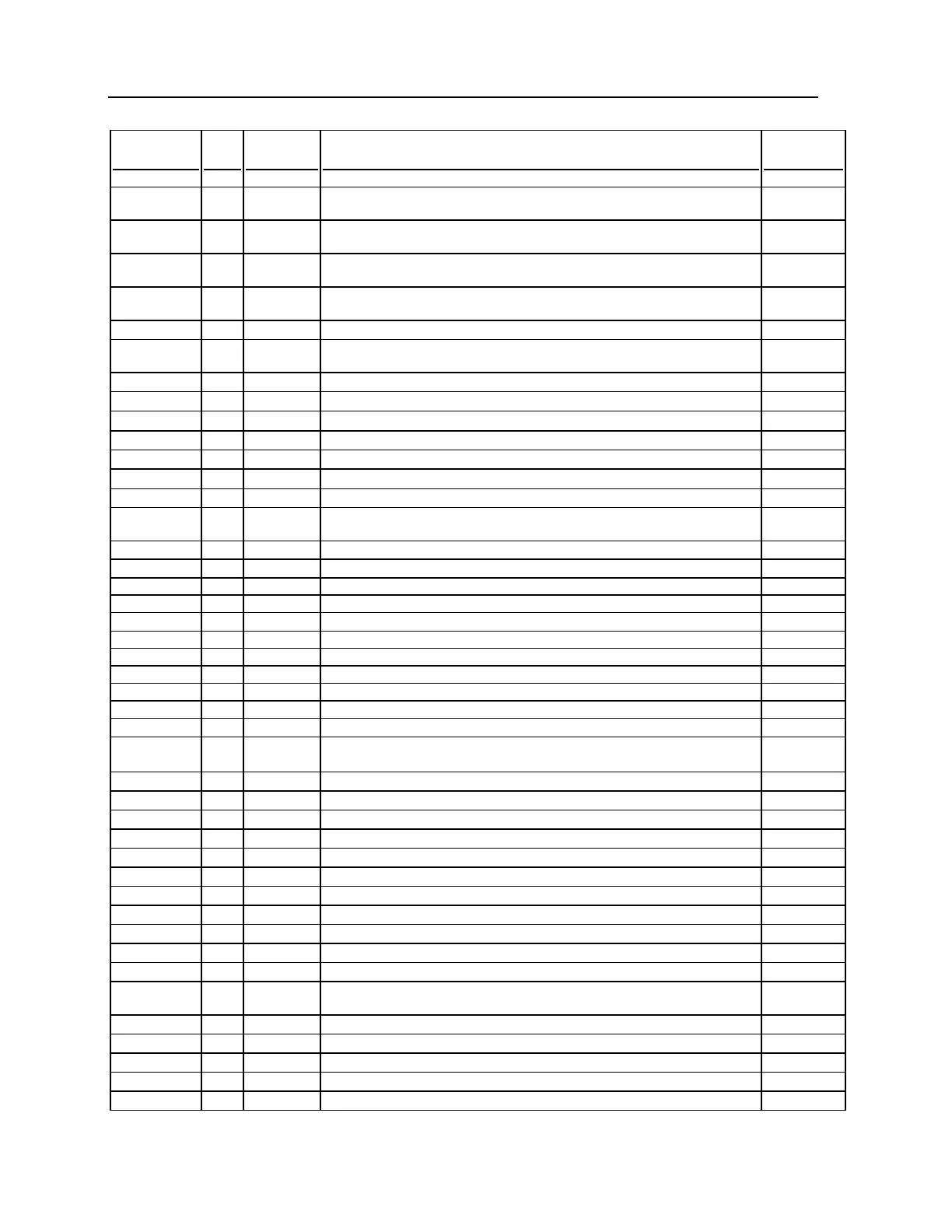

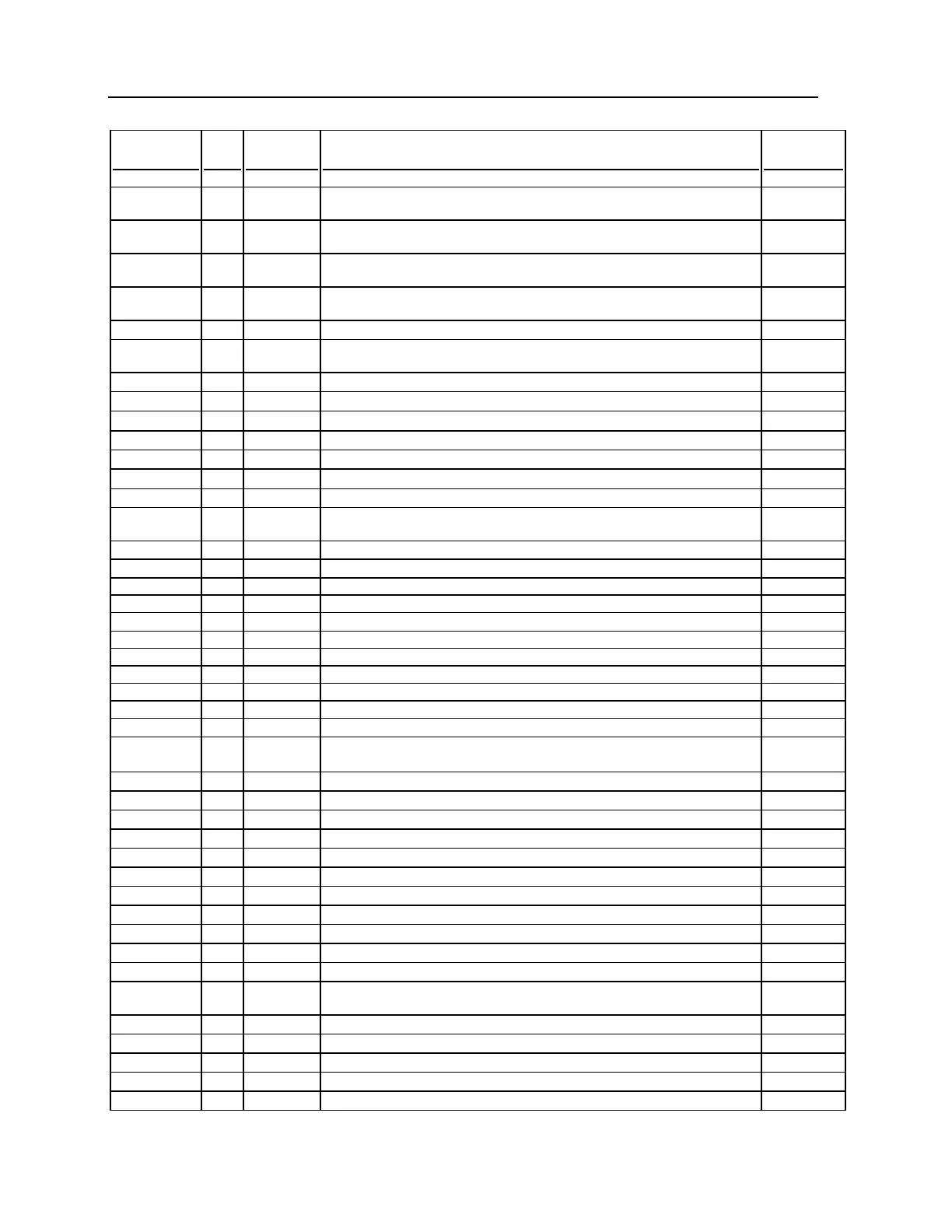

104 Model 10000 30-foot Parts & Specifications Manual Part # 99905185

FREQUENCY ITEM KEY INSPECTION DESCRIPTION STATUS

All bolts, fasteners and retaining rings for tightness, wear and

corrosion.

Hydraulic pumps and motors for leakage at fittings, seals, and

between sections. Check tightness of mounting bolts.

Transmission/PTO for leakage, abnormal vibration & noise,

alignment, and mounting bolt torque.

Quality of hydraulic fluid and presence of water.

Hoses & tubes for leakage, abrasion damage, blistering, cracking,

deterioration, fitting leakage, and secured properly.

Load hook for abnormal throat distance, twist, wear, and cracks.

Presence of operator's manual with unit.

All daily inspection items.

All monthly inspection items.

Rotation bearing for proper torque of all mounting bolts.

Base mounting bolts for proper torque.

All structural members for deformation, cracks and corrosion.

• Stabilizer beams and legs

Pins, bearing, shafts, gears, rollers, and locking devices for wear,

cracks, corrosion and distortion.

• Inner boom pivot pin(s) and retainer(s)

• Outer boom pivot pin(s) and retainer(s)

• Inner boom cylinder pin(s) and retainer(s)

• Outer boom cylinder pin(s) and retainer(s)

• Extension cylinder pin(s) and retainer(s)

• Jib boom pin(s) and retainer(s)

• Jib cylinder pin(s) and retainer(s)

• Jib extension cylinder pin(s) and retainer(s)

Hoses, fittings and tubing for proper routing, leakage, blistering,

deformation and excessive abrasion.

• Pressure line(s) from pump to control valve

• Return line(s) from control valve to reservoir

• Suction line(s) from reservoir to pump

• Pressure line(s) from control valve to each function

• Load holding valve pipe(s) and hose(s)

Loading...

Loading...