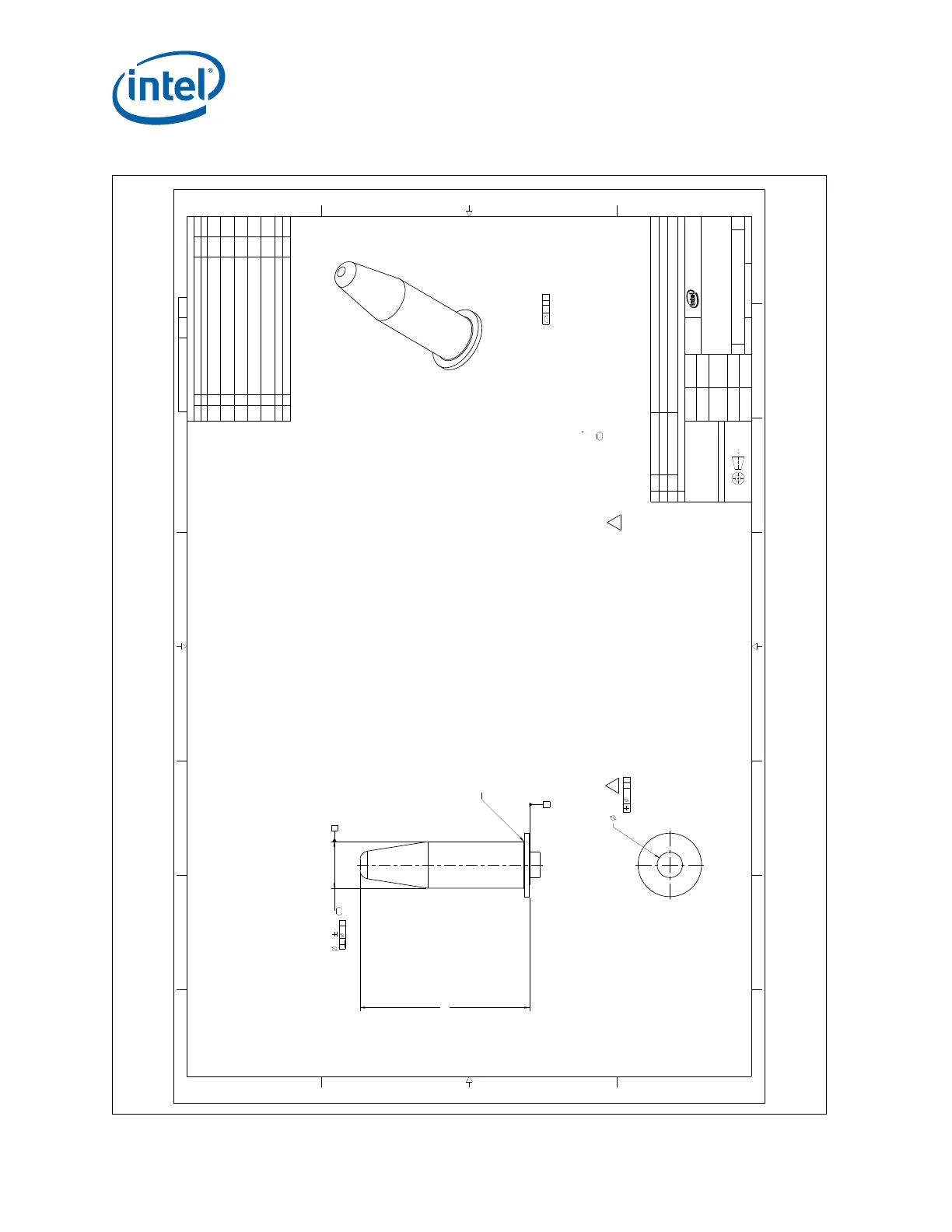

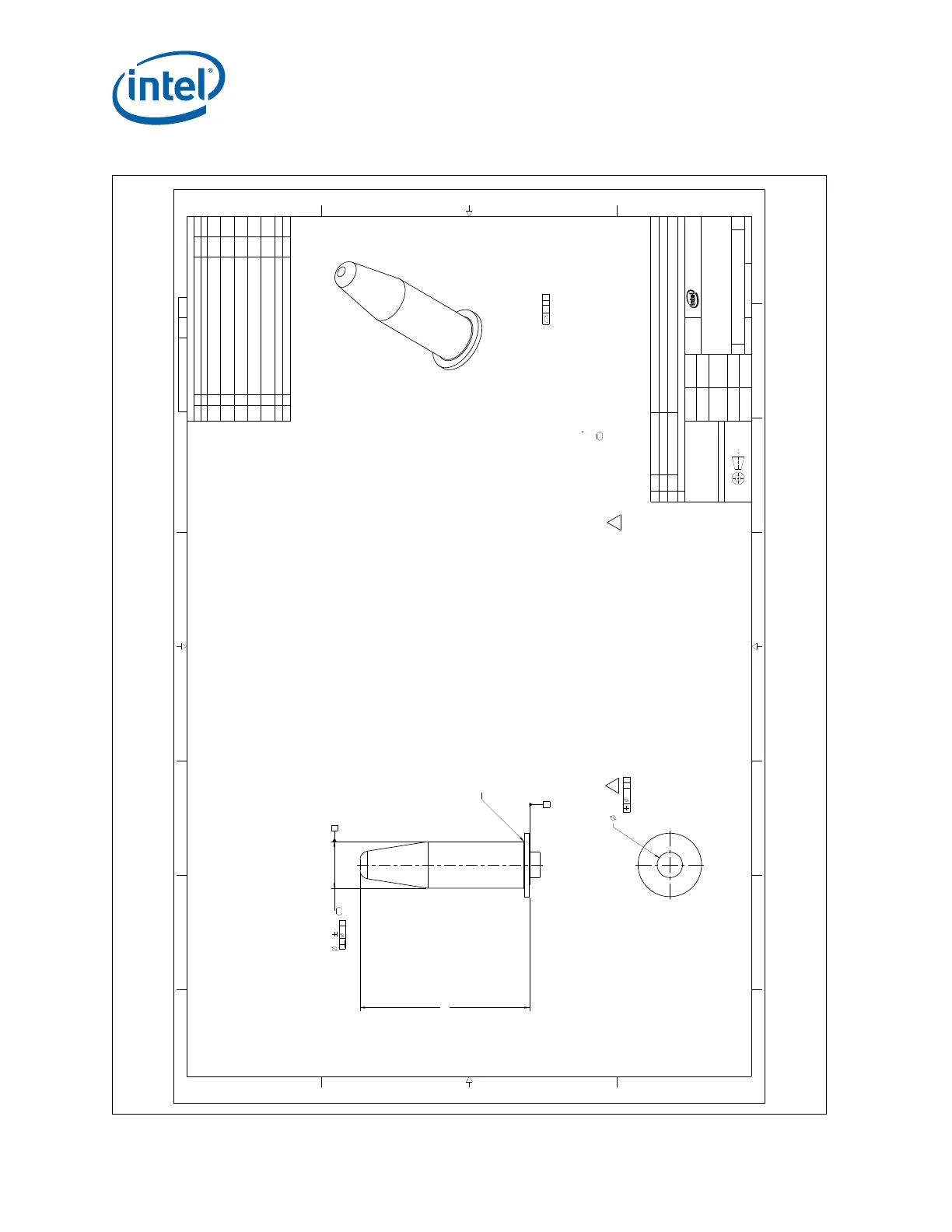

Figure E-18. Bolster Plate, Large Guide Post

13

4

5678

B

C

D

A

123

4

5678

B

C

D

A

B

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

.05 B A

.2 A B

.1 A

5.5 0.1

3 MAX

20±0.25

A

G94443 1 08

DWG. NO SHT. REV

SHEET 1 OF 1

DO NOT SCALE DRAWING

SCALE: 9:1

08G94443D

REV

DRAWING NUMBER

SIZE

KNL BOLSTER LARGE GUIDE POST

TITLE

DEPARTMENT

SEE NOTESSEE NOTES

FINISHMATERIAL

-

DATEAPPROVED BY

9/11/15

DATECHECKED BY

8/16/13

DATEDRAWN BY

8/16/13

DATEDESIGNED BY

DIMENSIONS ARE IN MILLIMETERS

THIRD ANGLE PROJECTION

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPR

- 01 TOOLING RELEASE 9/5/14

7A 02

1. ADDED TAPER TO POST. ROLLED THE PART NUMBER TO -002.

2. CHANGED POST INTERFACE DIAMETER FROM 2.5MM TO 3.0MM.

3. UPDATED NOTE 2 AND ADDED NOTE 7.

12/10/14

A3

ALL

B3

03

1. REVISED PART NUMBER TO -003.

2. REMOVED BASE TAPER.

3. REMOVED NOTE 4 AND 6.

03/25/15

7-C 04

1. REMOVED 8MM AND 3.26MM DIMENSIONS

2. INCREASED TOLERANCE FROM .1MM TO .25MM ON 20MM DIMENSION.

04/15/15

3-B 05 1. ADD NOTE 6 TO CALL OUT CRITICAL TO DIMENSIONS. 4/23/15

6-A

2-B

06

1. CHANGED DIMENSION TO STATE MAX 3.0 AND CALLOUT #7 SYMBOL

2. ADDED NOTE 7 TO CALLOUT REQUIRED PUSH OUT FORCE.

3. ADDED GD&T FEATURE CONTROL FRAMES.

8/28/15

B-6 07 1. ADDED OPTIONAL CHAMFER/RADIUS TO AID IN ASSEMBLY OF PART. 10/01/15

C-7 08 1. CHANGED FEATURE CONTROL FRAME DIMENSION FROM 0 TO 0.1 10/15/15

NOTES: UNLESS OTHERWISE SPECIFIED:

1. REFERENCE DOCUMENTS

ASME Y14.5M-2009 - STANDARD DIMENSION AND TOLERANCES

2. FEATURES NOT SPECIFIED ON DRAWING AND FEATURES WITHOUT SPECIFIED TOLERANCE

SHALL BE CONTROLLED BY 3D CAD DATABASE. FOR FEATURES NOT EXPLICITLY TOLERANCED:

(BASIC DIMENSIONS FROM THE 3D CAD MODEL).

3. DIMENSIONS ARE IN MILLIMETERS

4. MATERIAL: 18-8 STAINLESS STEEL; AISI 303, 304, 305; JIS SUS304; OR EQUIVALENT

5. PROCESS TEST: 168 HRS 85

C / 85% HUMIDITY WITH NO VISIBLE CORROSION.

6. DIMENSIONS MARKED ARE CRITICAL TO FUNCTION DIMENSIONS (CTF).

7 SUPPLIER DEFINED DIAMETER TO MEET PRESS FIT SEPARATION FORCE REQUIREMENT.

SEE APPLICABLE BOLSTER PLATE ASSEMBLY DRAWING.

- PUSHOUT FORCE > 89N (20LBF)

7

CHAMFER TO CORNER (MAX 1.0 HEIGHT) OR 1.0MM

RADIUS MAX CAN BE ADDED AS AND OPTION

FOR STRUCTURAL INTEGRITY DURING ASSEMBLY

C

C

PARTS LIST

DESCRIPTIONPART NUMBER

ITEM NO

QTY

KNL BOLSTER LARGE GUIDE POSTG94443-003TOP

Loading...

Loading...