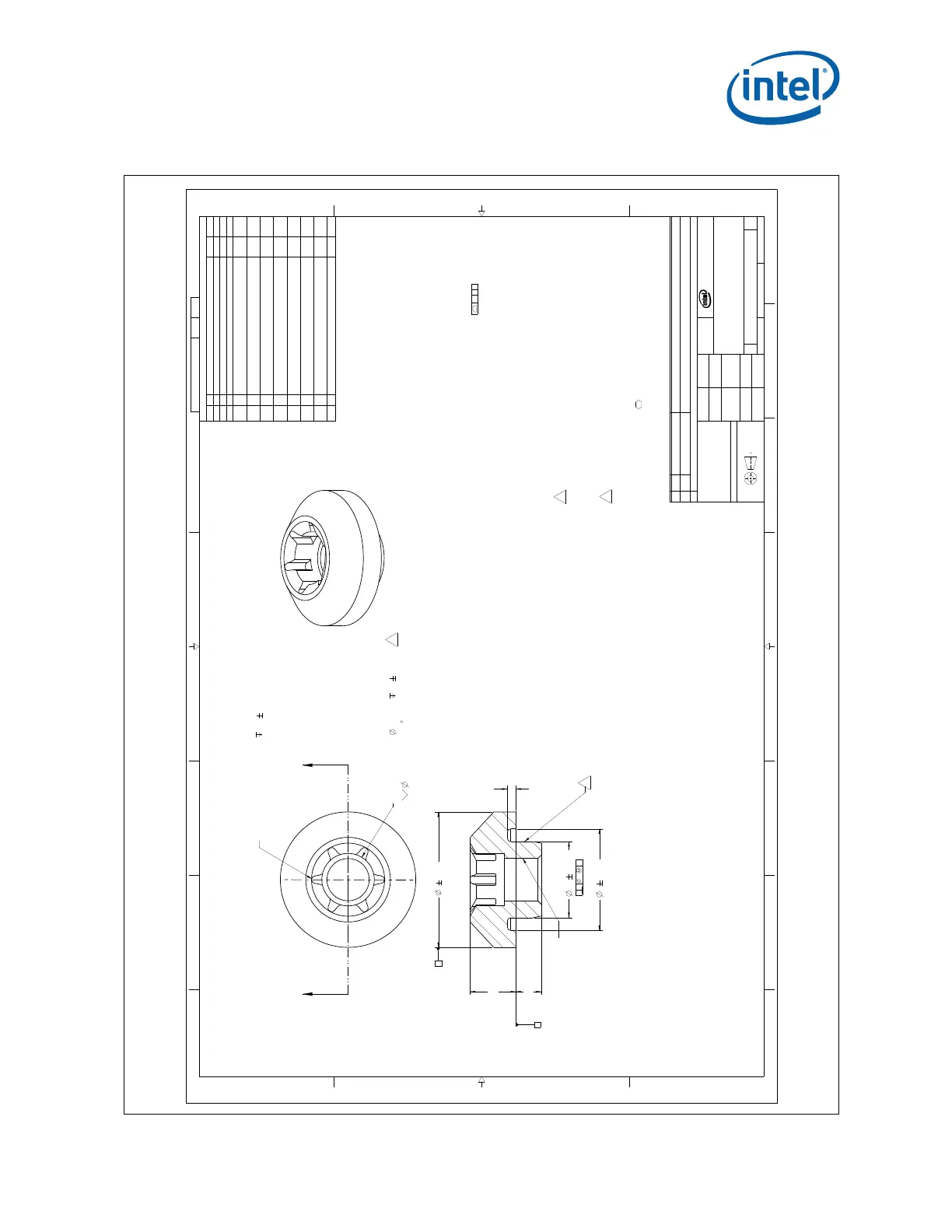

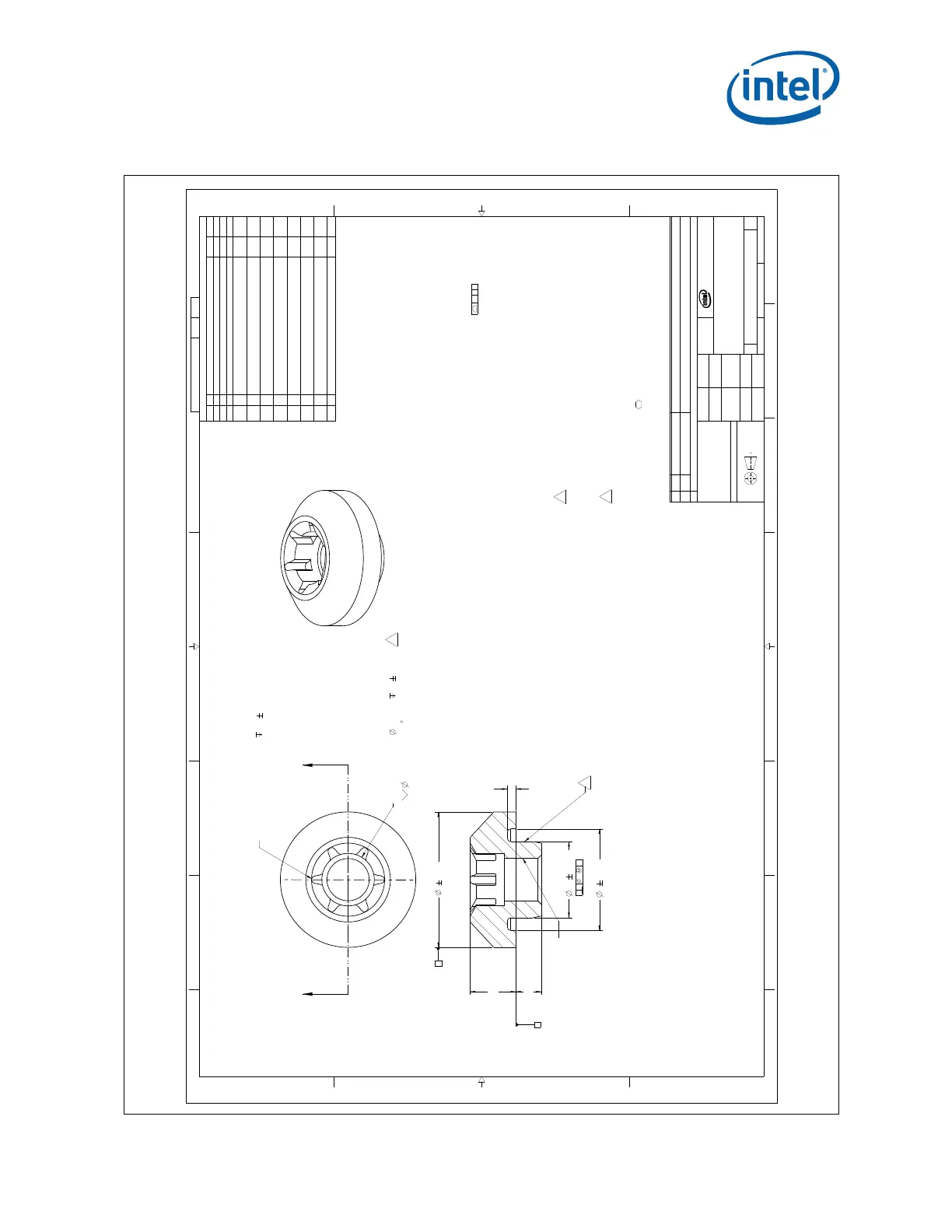

Figure E-25. Bolster Plate, M3 Captive Nut

A A

13

4

5678

B

C

D

A

123

4

5678

B

C

D

A

B

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

R

.2 A B

.2 A

CLEARANCE HOLE 2.0 0.25 7

4.32+0/-0.25 X120

3.1

+0.2

-0.1

4.5 0.05

2.69±0.08

1.51±0.08

6 0.05

0.5±0.05

8 0.12

A

H19328 1 11

DWG. NO SHT. REV

SHEET 1 OF 1

DO NOT SCALE DRAWING

SCALE: 14:1

11H19328D

REV

DRAWING NUMBER

SIZE

SOCKET P M3 BOLSTER CAPTIVE NUT

TITLE

DEPARTMENT

SEE NOTESSEE NOTES

FINISHMATERIAL

--

DATEAPPROVED BY

-

9/10/2013

DATECHECKED BY

9/10/2013

DATEDRAWN BY

8/8/2013

DATEDESIGNED BY

DIMENSIONS ARE IN MILLIMETERS

THIRD ANGLE PROJECTION

PARTS LIST

DESCRIPTIONPART NUMBER

ITEM NO

QTY

SOCKET P M3 BOLSTER CAPTIVE NUTH19328-002TOP

REVISION HISTORY

ZONE REV DESCRIPTION DATE APPR

- 01 TOOLING RELEASE 9/10/2013

02 UPDATED NOTE 2 AND 6. 12/10/14

03 REMOVED NOTE REGARDING DIMENSIONS ARE CRITICAL TO FUNCTION. 3/26/15

04

1. ROLLED PART NUMBER FROM -001 TO -002.

2. CHANGED GEOMETRY.

4/15/15

05 1. ADDED NOTE 8 TO CALL OUT CRITICAL TO FUNCTION DIMENSIONS. 4/23/15

06 1. THREAD CALLOUT ON BOTTOM VIEW ADDED. 5/1/15

PG1 8B 07 1. REMOVED CTF CALLOUT FOR INTERNAL THREAD NOTE. 5/21/15

B-3 08 1. UPDATED NOTE 5 TO CALLOUT -004 COLLAR 8/28/15

B6

C6

B7

09

1. REMOVED FLATNESS CALLOUT

2. REMOVED FEATURE CONTROL FRAME

3. DELETED DUPLICATE DIMENSIONING

10/15/15

B8

C6

10

1. INCREASED TOLERANCE RANGE FROM 0.04 TO 0.08.

2. INCREASED TOELRANCE RANGE FROM +/-0.1 TO +0.2/-0.1

2/11/16

B6 11 1. REMOVED TWO CTF DIMENSIONS. 7/11/16

NOTES UNLESS OTHERWISE SPECIFIED

1. REFERENCE DOCUMENTS

ASME Y14.5M - 2009 - STANDARD DIMENSION AND TOLERANCES

UL1439 - UL SHARP EDGE TESTING

2. FEATURES NOT SPECIFIED ON DRAWING SHALL BE CONTROLLED BY

3D CAD DATABASE. FOR FEATURES NOT EXPLICITLY TOLERANCED:

(BASIC DIMENSIONS FROM THE 3D CAD MODEL).

3. MATERIAL:

-LOW CARBON STEEL 1144, HARDEN AND TEMPER

-CRITICAL MECHANICAL PROPERTIES: 345 MPa MIN YIELD STRENGTH

-MAY USE INTEL ENGINEERING APPROVED EQUIVALENT

4. FINISH:

-2 MICROMETER MIN ELECTROLYTIC NICKEL PLATING

-PROCESS TEST 168 HRS 85 DEGREE C / 85% HUMIDITY WITH NO

VISIBLE CORROSION

5 INTERFERENCE FIT WITH PART H19329-003.

MINIMUM 50LBF SEPARATION FORCE WITH PRESS FIT COLLAR

6. SHARP CORNERS MUST BE CHAMFERED, OR ROUNDED TO 0.1MM

RADIUS MAX

7 DRILL CLEARANCE HOLE TO CLEAN UP CHIP/BURRS FROM TAPPING

& FORMING OPERATIONS, SHOULD ALLOW M3 STUD TO PASS THROUGH

WITHOUT INTERFERENCE

8. DIMENSIONS MARKED ARE CRITICAL TO FUNCTION

DIMENSIONS (CTF).

6 POINT T-20 DRIVE FEATURE 1.5 0.25

SECTION A-A

5

M3 X 0.5 CLASS 6H

INTERNAL THREAD THRU ALL

C

Loading...

Loading...