Socket Mechanical Design

Intel

®

Xeon

®

Phi™ Processor x200 Product Family TMSDG Order Number: 334785-002

30

.

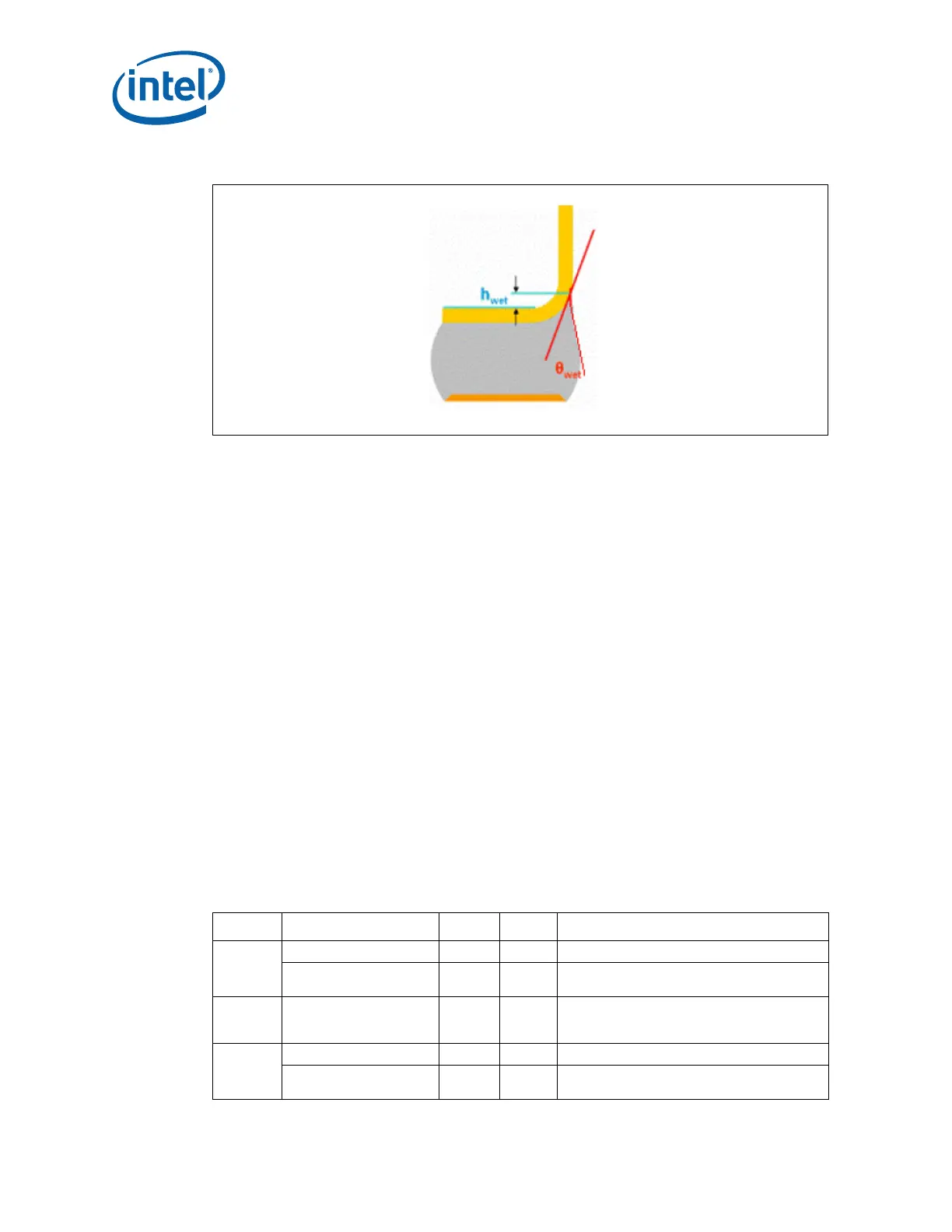

Figure 3-9. Wetting Angle and Wetting Height

3.4 Socket Size

The socket size will meet the dimensions as shown in Appendix D, allowing full insertion

of the package into the socket without interference. This information should be used in

conjunction with the reference main board keep-out drawings provided in Appendix F to

ensure compatibility with the reference thermal mechanical components.

3.5 Actuation and Insertion Requirements

3.5.1 Package Translation

The socket should be built so that the post-actuated seating plane of the package is

flush with the seating plane of the socket. Movement will be along the axis normal to

the seating plane.

3.5.2 Insertion/Removal/Actuation Forces

Any actuation will meet or exceed SEMI S8-95 Safety Guidelines for

Ergonomics/Human Factors Engineering of Semiconductor Manufacturing Equipment,

example Table R2-7 (Maximum Grip Forces), available at http://www.semi.org/.

The socket is designed so that no force is required to insert the package into the

sock

et, and no tool is required to insert or remove the package

.

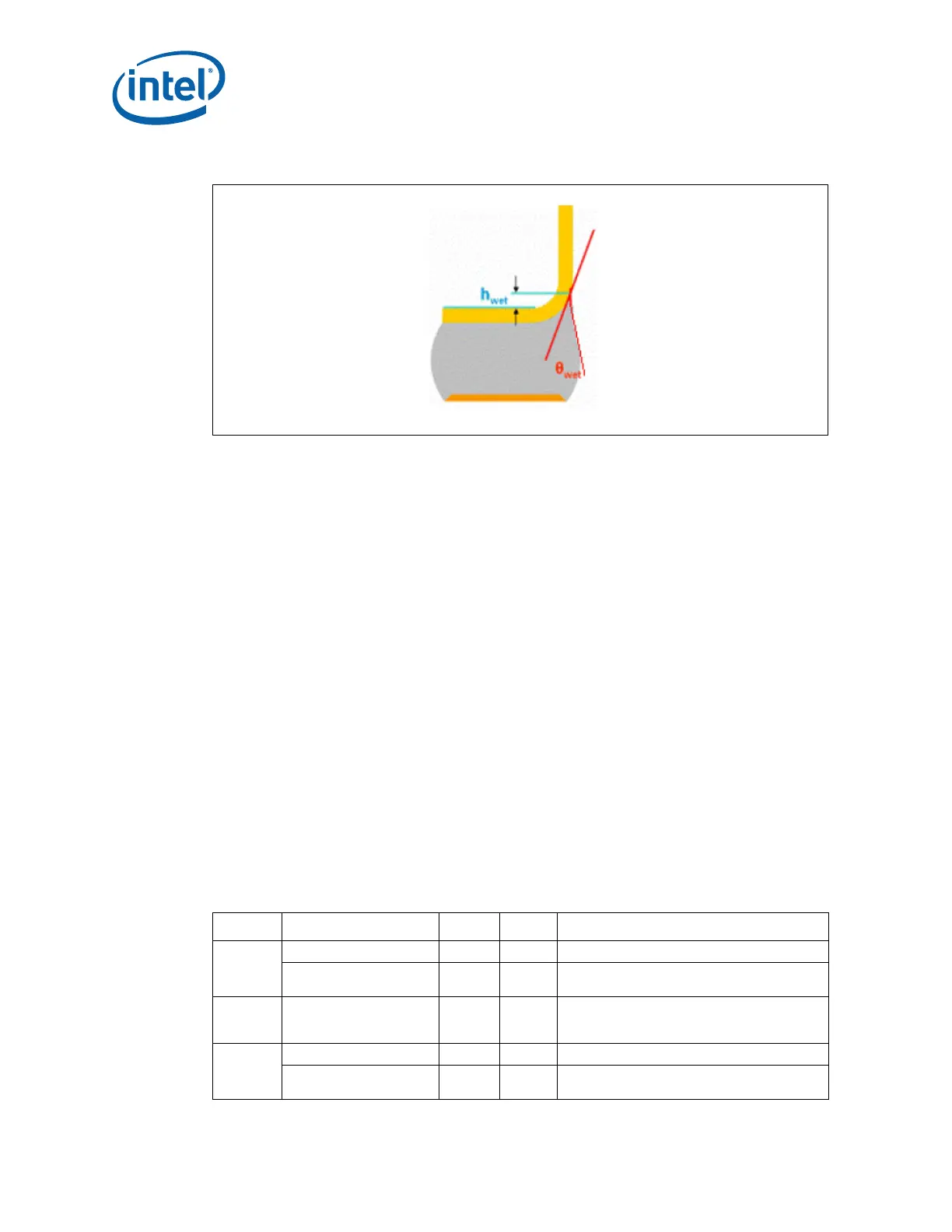

Table 3-3. PnP Cover Ergonomics Requirements

Direction Description Min. Max. Comments

Vertical Closed position at 260

°C 0.75 lbf - While holding at reflow temp.

Closed position at room

temper

ature.

3 lbf 22 lbf Pull off force for cap removal.

In and

Ou

t of

Plane

Shock 0.8 lbf - During shipping.

In-Plane Removal - 1.7 lbf Will meet Ergonomic requirements.

PnP Cap - - +/- 3.5 mils placement accuracy; in-plane

sl

ack.

Loading...

Loading...