JOHNSON CONTROLS

108

FORM 145.05-NOM7

ISSUE DATE: 10/31/2019

SECTION 5 – SEQUENCE OF OPERATION

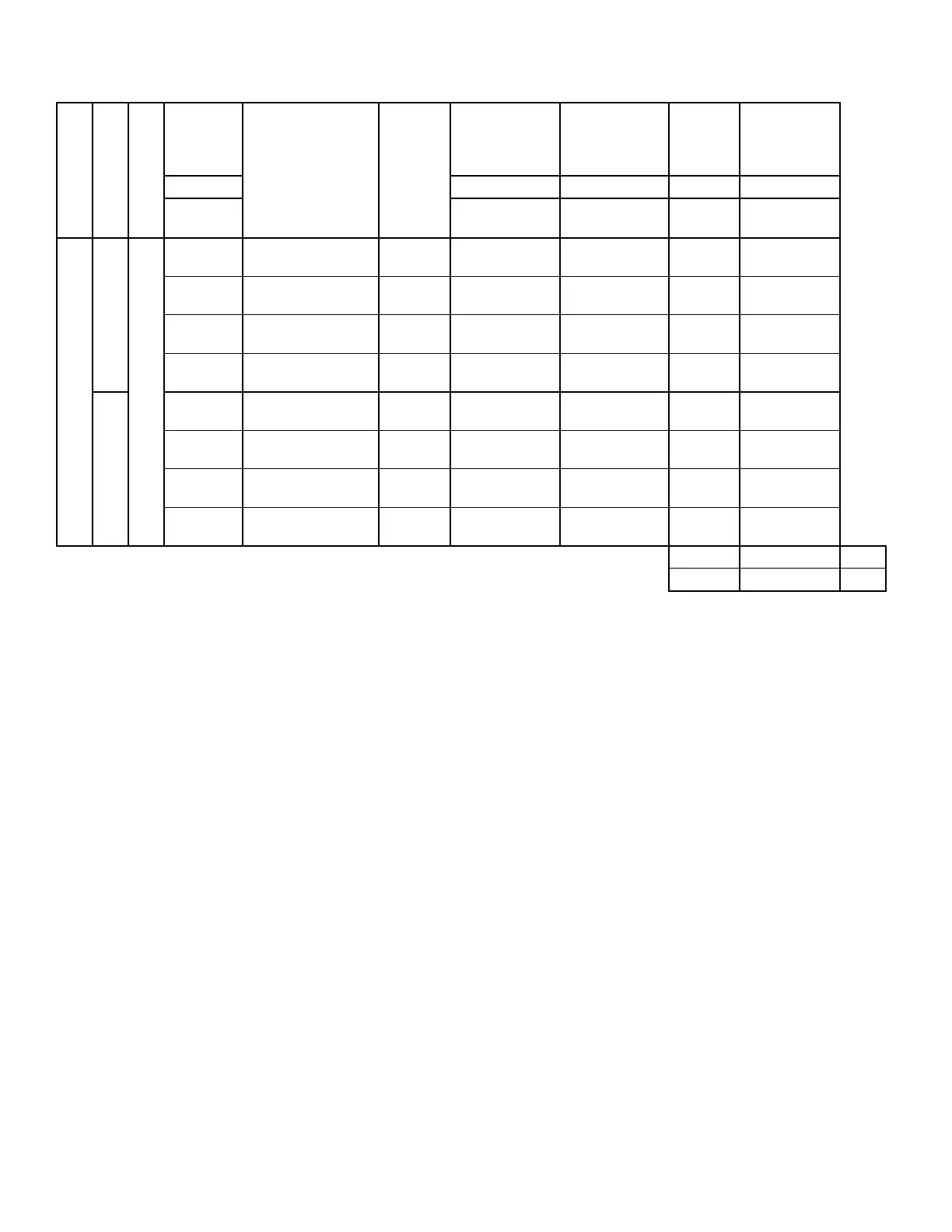

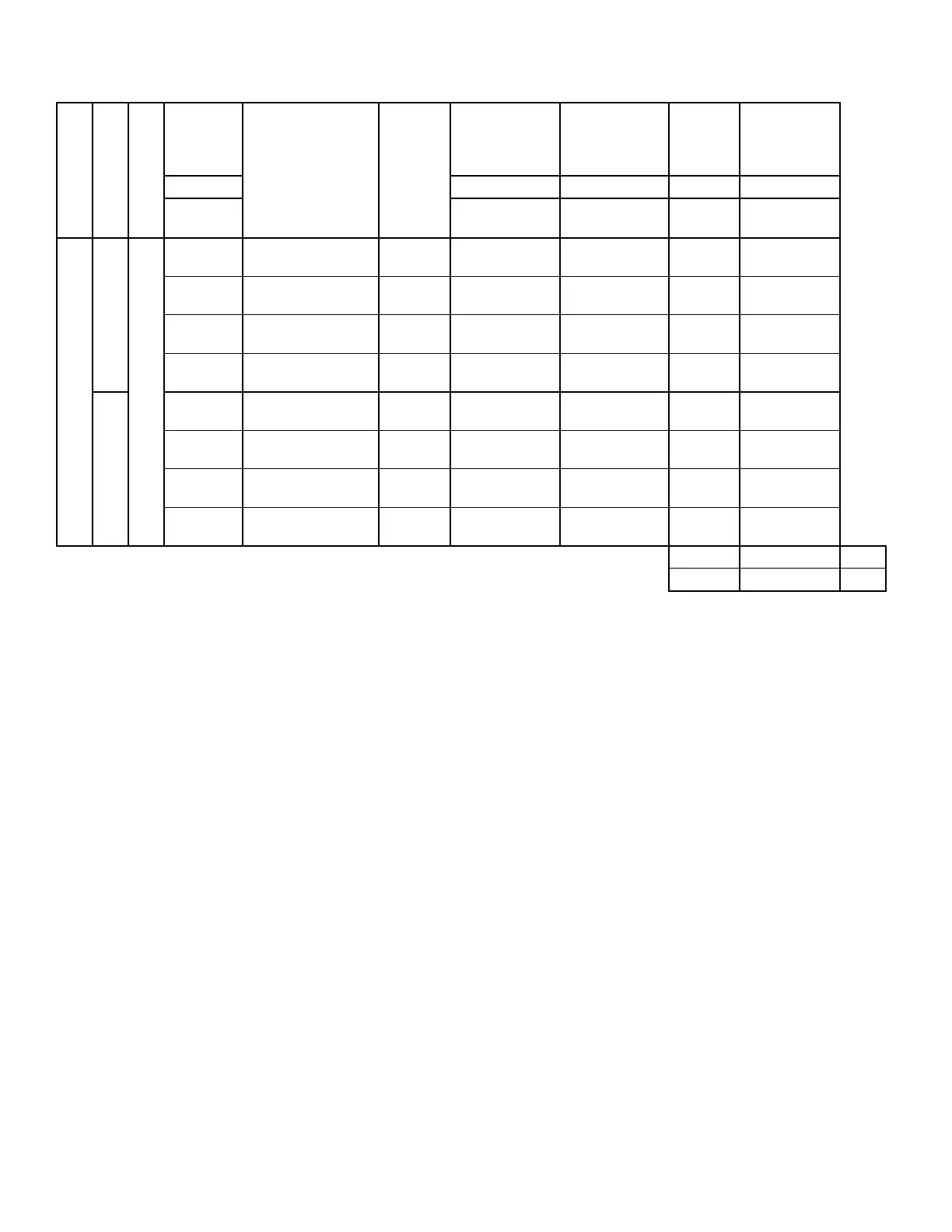

CABINET SIZE

MODEL

FAN TYPE

FAN

DIAMETER

FAN MODEL

FAN

VENDOR

FAN

ONLY

FAN W/

PIEZORING

K

FACTOR

EXAMPLE

CALCULATED

AIRFLOW @

4.0 IN.WG.

INCHES P/N P/N k CFM

CFM =

KX√(IN.WG)

Large

LSWU095

Airfoil Plenum Fan (SWSI)

36

9 blade EPF wheel,

special housing

TWIN

CITY

026 42645 101 026 42645 101 7032.01 14064

36

12 blade EPQ wheel,

special housing

TWIN

CITY

026 42645 102 026 42645 101 7032.01 14064

40

9 blade EPF wheel,

special housing

TWIN

CITY

026 42646 101 026 42646 101 8555.41 17111

40

12 blade EPQ wheel,

special housing

TWIN

CITY

026 42646 102 026 42646 101 8555.41 17111

LSWU105

36

9 blade EPF wheel,

special housing

TWIN

CITY

026 42645 101 026 42645 101 7032.01 14064

36

12 blade EPQ wheel,

special housing

TWIN

CITY

026 42645 102 026 42645 101 7032.01 14064

40

9 blade EPF wheel,

special housing

TWIN

CITY

026 42646 101 026 42646 101 8555.41 17111

40

12 blade EPQ wheel,

special housing

TWIN

CITY

026 42646 102 026 42646 101 8555.41 17111

855.4 1710.8 Min

10017.8 20035.6 Max

Return Air Temperature Sensor

All units require the installation of a return air sensor.

However, because of the variation of the return air ar-

rangements for this product, the return air sensor is

shipped loose in the control enclosure and must be field

installed and wired to the Unit Controller. The sensor

is supplied with 25-foot leads terminated to plug onto

the Unit Controller. If a longer length is required, inline

butt splices can be used to increase the length. It is im-

portant the return air sensor be located so it senses the

true Return Air Temperature. The sensor is connected

at the J9 terminal strip, terminals 3 and 4.

Occupied Standby

The Unit Controller determines there is no demand

for cooling or heating based on the Current RAT and

the corresponding Cooling RAT and Heating RAT set-

points. The Supply Fan is ON and controlling the ac-

tive duct static pressure setpoint.

Unoccupied Standby

The Unit Controller determines there is no demand

for cooling or heating based on the Current RAT and

the corresponding Cooling RAT and Heating RAT set-

points. The Supply Fan is ON and controlling the Ac-

tive duct static pressure setpoint.

Occupied Cooling

In the OCCUPIED COOLING mode, the Unit Con-

troller monitors the RETURN AIR TEMP and com-

pares it to the “RAT COOLING SETPOINT.” The

“RAT COOLING SETPOINT” is entered into the Unit

Controller through the SETPOINTS key, COOLING

subsection of the User Interface. If the RETURN AIR

TEMP is equal to or greater than the “RAT COOL-

ING SETPOINT” plus 0.5°F, the Unit Controller

places the unit in the OCCUPIED COOLING mode

until the RETURN AIR TEMP is equal to or less than

the “RAT COOLING SETPOINT” minus 0.5°F.

Occupied Heating

In the OCCUPIED HEATING mode, the Unit Control-

ler monitors the RETURN AIR TEMP and compares

it to the “RAT HEATING SETPOINT.” The “RAT

HEATING SETPOINT” is entered into the Unit Con-

troller through the SETPOINTS key, HEATING sub-

section of the User Interface. If the RETURN AIR

TEMP is equal to or less than the “RAT HEATING

SETPOINT” minus 0.5°F, the Unit Controller places

the unit in the OCCUPIED HEATING mode.

TABLE 20 - PIEZOMETER AIRFLOW MEASUREMENTS (CONT'D)

Loading...

Loading...