JOHNSON CONTROLS

114

FORM 145.05-NOM7

ISSUE DATE: 10/31/2019

SECTION 5 – SEQUENCE OF OPERATION

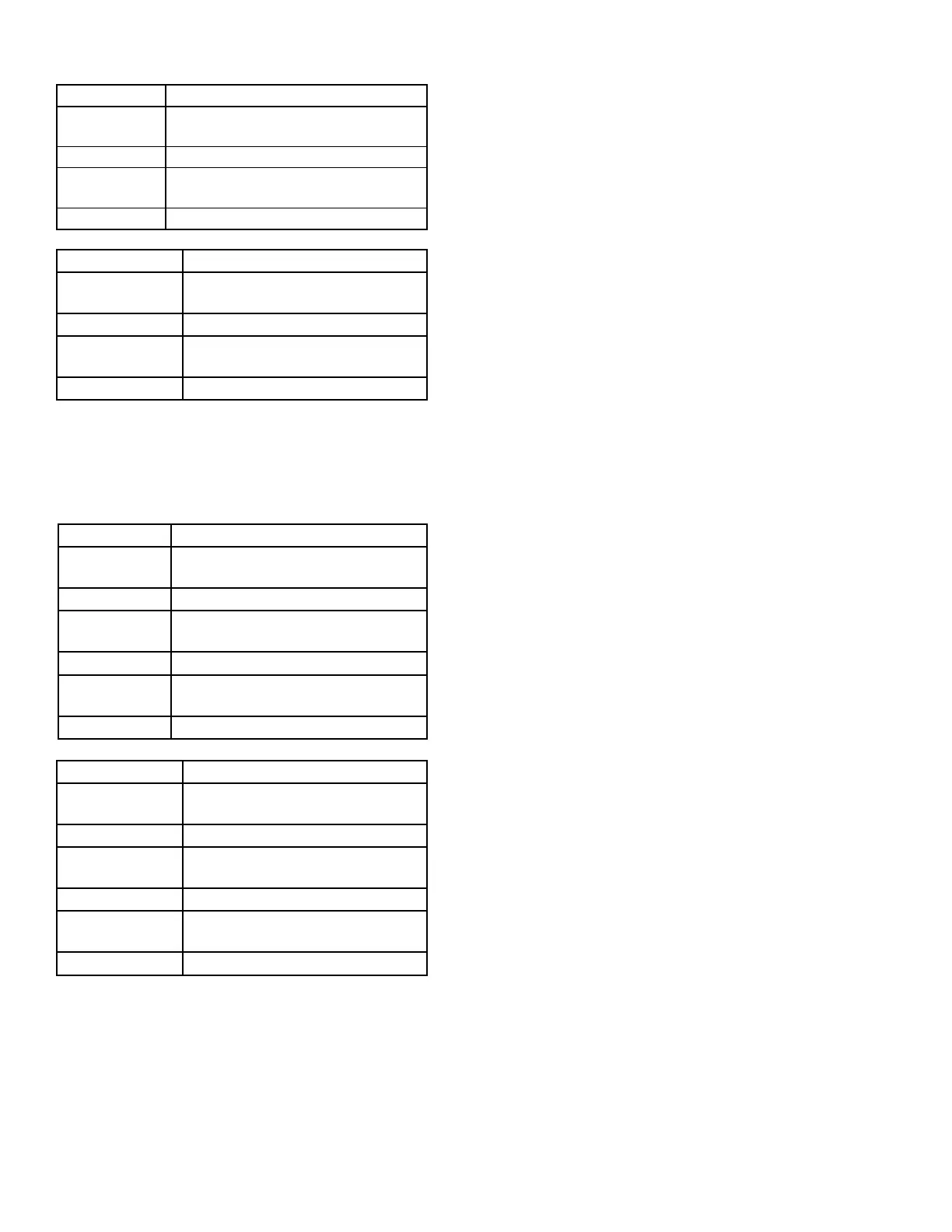

STAGING UP NEXT STAGE TO ENABLE

Stage 0 to 1

Compressor C or D with the fewest

number of starts.

Stage 1 to 2 Compressor C or D not on.

Stage 2 to 3

Compressor A or B with the fewest

number of starts.

Stage 3 to 4 The remaining compressor that is off.

STAGING DOWN NEXT STAGE TO DISABLE

Stage 4 to 3

Compressor A or B with the fewest

number of starts.

Stage 3 to 2 Compressor A or B that is on.

Stage 2 to 1

Compressor C or D with the fewest

number of starts.

Stage 1 to 0 The remaining compressor that is off.

Six Compressor Units (095, 105 Models)

UNIT SIZE must be set through the User Interface,

OPTIONS key, UNIT DATA subsection. The correct

unit size is selected from the available options.

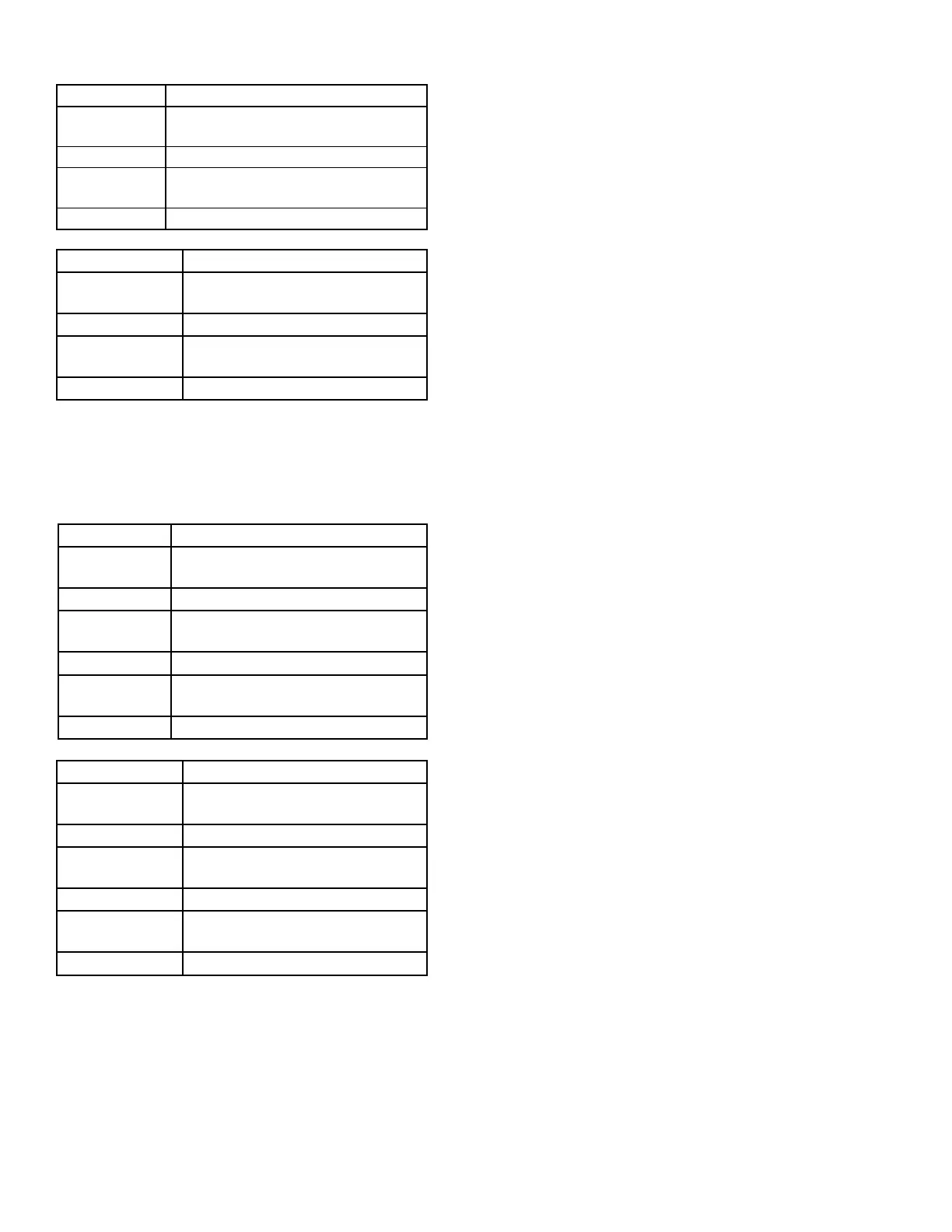

STAGING UP NEXT STAGE TO ENABLE

Stage 0 to 1

Compressor E or F with the fewest

number of starts.

Stage 1 to 2 Compressor E or F not on.

Stage 2 to 3

Compressor C or D with the fewest

number of starts.

Stage 3 to 4 Compressor C or D not on.

Stage 4 to 5

Compressor A or B with the fewest

number of starts.

Stage 5 to 6 The remaining compressor that is off.

STAGING DOWN NEXT STAGE TO DISABLE

Stage 6 to 5

Compressor A or B with the fewest

number of starts.

Stage 5 to 4 Compressor A or B that is on.

Stage 4 to 3

Compressor C or D with the fewest

number of starts.

Stage 3 to 2 Compressor C or D that is on.

Stage 2 to 1

Compressor E or F with the fewest

number of starts.

Stage 1 to 0 The remaining compressor on.

COMPRESSOR OPERATION

Compressor Data

The Unit Controller records the following data per-

tinent to compressor operation for each compressor.

This assists the Service Technician and assures equal

wear on all of the compressors in the unit.

COMPRESSOR STARTS – Each time one of the

compressors state transitions from OFF to ON, the

“COMPRESSOR # STARTS” is incremented by one,

where # varies to match the compressor number the

data is recorded for (A, B, C, etc.). View this data under

the OPERATING HOURS/START COUNTER key of

the User Interface.

COMPRESSOR OPERATING HOURS – While the

compressor is in the ON state, the “COMPRESSOR #

OPER HRS” is incremented once for every hour of op-

eration. This value is accumulated over the lifetime of the

compressor. The # symbol varies to match the compressor

number the data is recorded for (A, B, C etc.). View this

data under the OPERATING HOURS/START COUN-

TER key of the User Interface.

COMPRESSOR RUN TIME – While the compressor

is in the ON state, the “COMPRESSOR # RUN TIME”

is incremented once per minute. The value only ac-

cumulates during the current run state and is reset to

zero when the COMPRESSOR RUN STATE switches

from ON to OFF. The # symbol varies to match the

compressor number the data is recorded for. View this

data under the COMPRESSOR SYSTEMS key of the

User Interface.

Compressor Ready to Run

To determine if a compressor is ready to run, the Unit

Controller monitors the following derived data while

the “COMPRESSOR # STATE” is OFF to make the

determination:

• “WRN-LOW WATER TEMP”

• “WRN-LOW WATER FLOW”

• “WRN-SUCT PRESS XDCR#”

• “WRN-DISC PRESS XDCR#”

• “LOCKOUT-LOW PRESS SYS #”

• “SUPPLY FAN STATUS”

• “AUTO RESET-COMPRESSOR SYSTEM

#-TRIP 1”

• “AUTO RESET-COMPRESSOR SYSTEM

#-TRIP 2”

• “AUTO RESET-COMPRESSOR SYSTEM

#-CLEAR”

• “LOCKOUT-COMP SAFETY SYS #”

If all of the above parameters are FALSE (not active)

and the minimum OFF time is satisfied, the compres-

sor is placed in the ready to run state.

Loading...

Loading...