Maintenance

October 2014 5-2 06-236115-001

5-3 PREVENTATIVE MAINTENANCE

Perform preventive maintenance per Table 5-1.

5-4 INSPECTION PROCEDURES

5-4.1 Daily

5-4.1.1 Check HFC-227ea Cylinder Pressure

Check the HFC-227ea cylinder pressure gauges for proper operating pressure. If the pressure

gauge indicates a pressure loss (adjusted for temperature) of more than 10%, or loss in agent

quantity shown on cylinder valve of more than 5%, it shall be refilled. Remove and recharge

the cylinder as instructed in Paragraph 5-7 and Paragraph 6-3.

5-4.1.2 Check Nitrogen Cylinder Pressure

Check the nitrogen cylinder for proper operating pressure. If the pressure loss (adjusted for

temperature) exceeds 10%, recharge with nitrogen to 1800 PSIG at 70°F (124 bar gauge at

21°C).

5-4.2 Monthly

5-4.2.1 General inspection

Make a general inspection survey of all cylinders and equipment for damaged or missing parts.

If the equipment requires replacement, refer to Paragraph 5-6.3.

5-4.2.2 Hazard access

Ensure access to hazard areas, manual pull stations, discharge nozzles, and cylinders are

unobstructed and that nothing obstructs the operation of the equipment or distribution of HFC-

227ea agent.

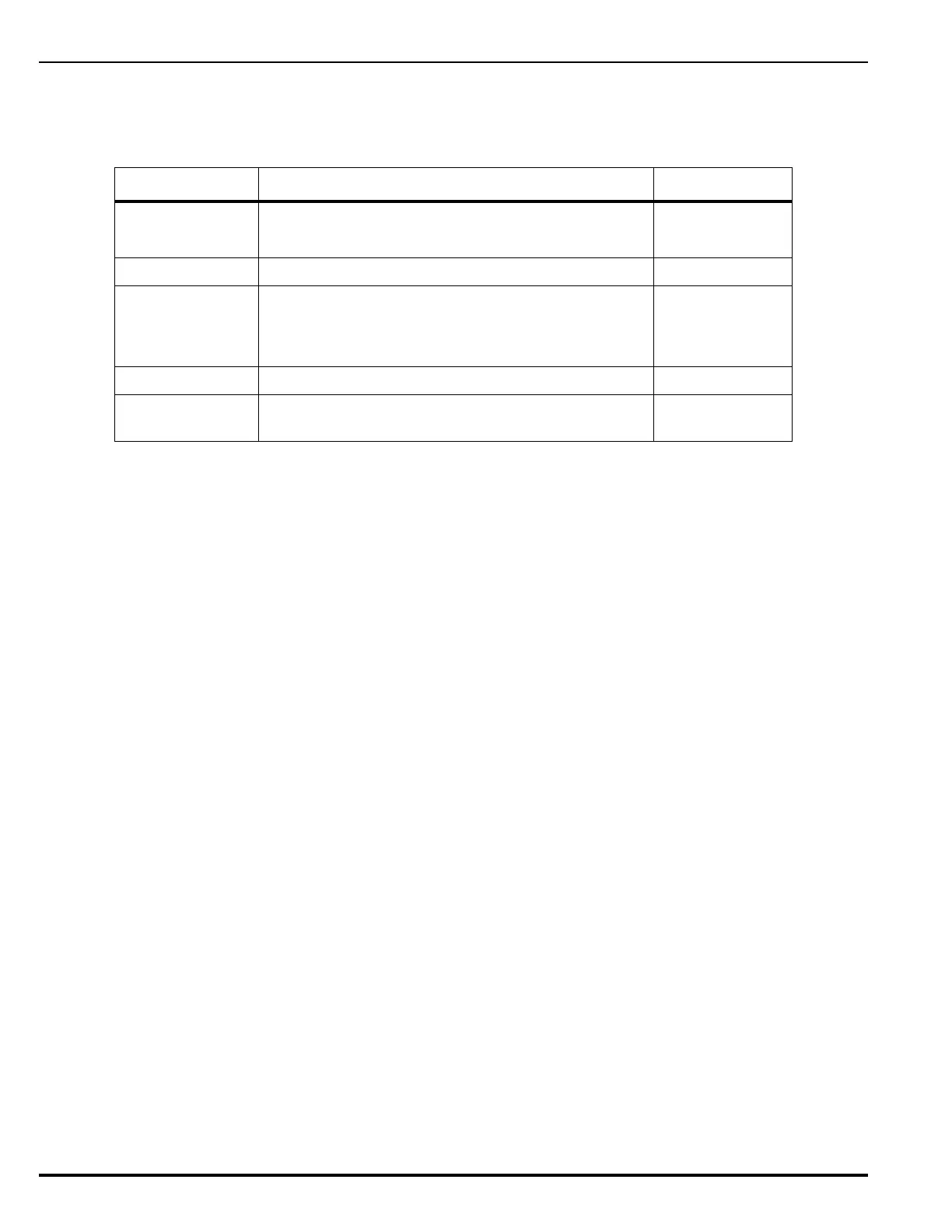

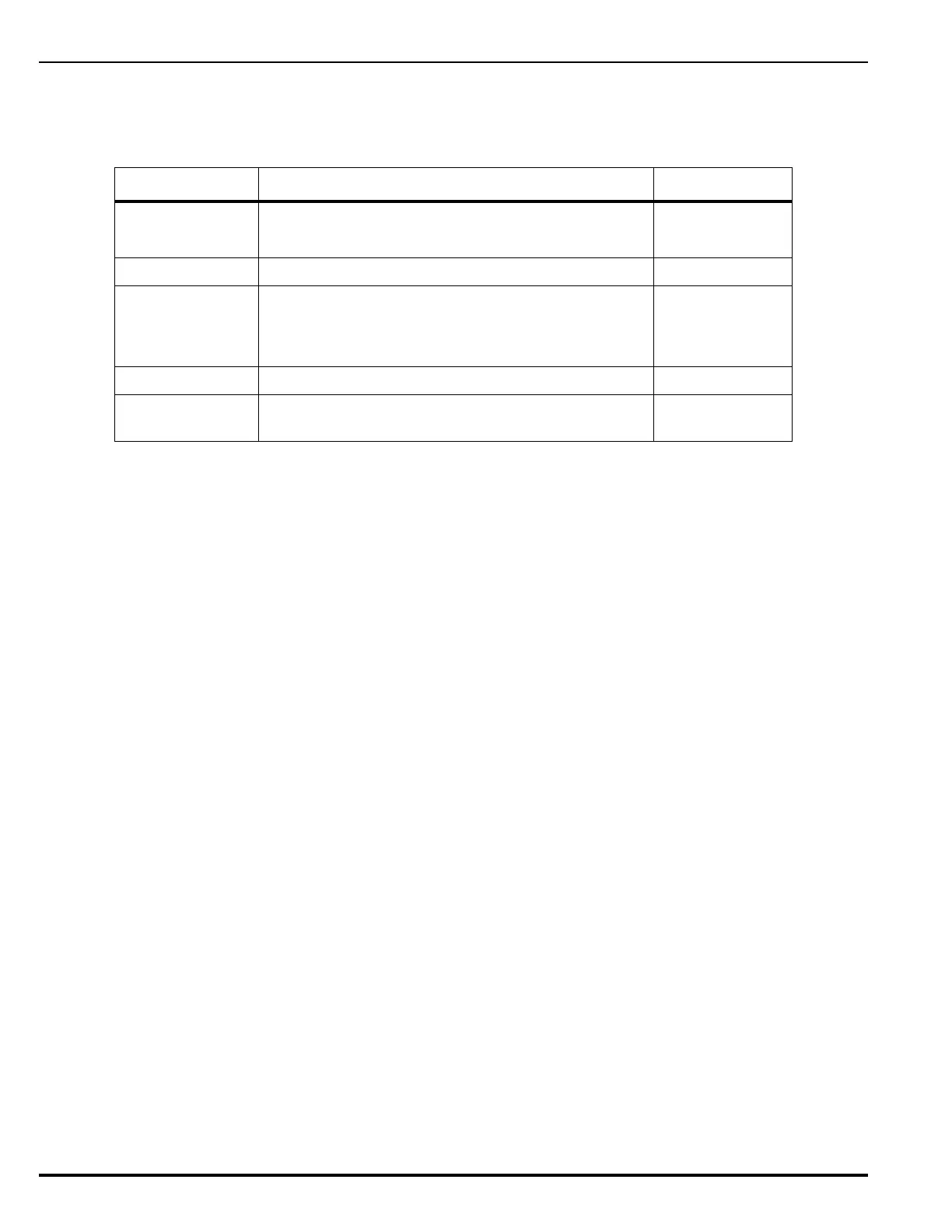

Table 5-1. Preventive Maintenance Schedule

Schedule Requirement Paragraph

Daily

Check

HFC-227ea cylinder pressures

Check Nitrogen cylinder pressures

5-4.1

Monthly Inspect hazard area system components 5-4.2

Semi-Annually Test pressure switches

Test electric control heads

Check HFC-227ea cylinder weights and pressures

5-4.3

Every 2 Years Blow out distribution piping 5-4.4

Every 5 Years

HFC-227ea and nitrogen cylinder and flexible hose

hydrostatic pressure test and/or inspection

5-5 and 6-4.1

Loading...

Loading...