4

LeeBoy Model 8510B Conveyor Paver 4-9

Specications

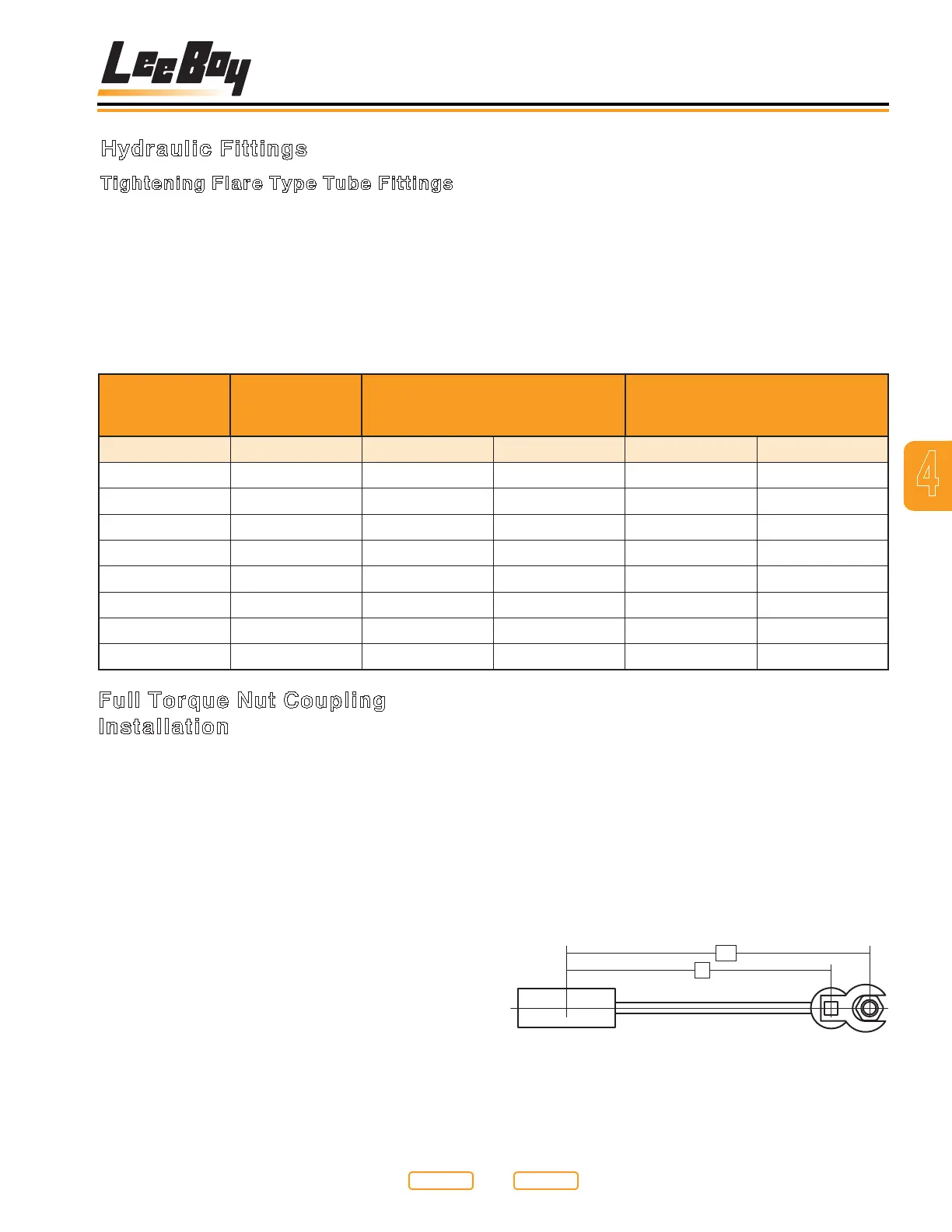

Table 4-12. Torque Specications For Flare Type Tube Fittings

TUBE SIZE OD

NUT SIZE

(ACROSS

FLATS)

TORQUE VALUE

RECOMMENDED TURNS TO

TIGHTEN (AFTER FINGER

TIGHTENING)

(in) (in) (N•m) (lb-ft) (N•m) (lb-ft)

3/16 7/16 8 6 1 1/6

1/4 9/16 12 9 1 1/6

5/16 5/8 16 12 1 1/6

3/8 11/16 24 15 1 1/6

1/2 7/8 46 34 1 1/6

5/8 1 62 46 1 1/6

3/4 1 1/4 102 75 3/4 1/8

7/8 1 3/8 122 90 3/4 1/8

3. Lubricate connection and hand tighten swivel nut

until snug.

4. To prevent twisting the tube(s), use two wrenches.

Place one wrench on the connector body and with

the second, tighten the swivel nut to the torque

shown in Table 4-12. Torque Specications For

Flare Type Tube Fittings.

NOTE: The torque values shown are based on

lubricated connections as in assembly.

Hydraulic Fittings

Tightening Flare Type Tube Fittings

1. Check the are and are seat for defects that might

cause leakage.

2. Align tube with tting before tightening.

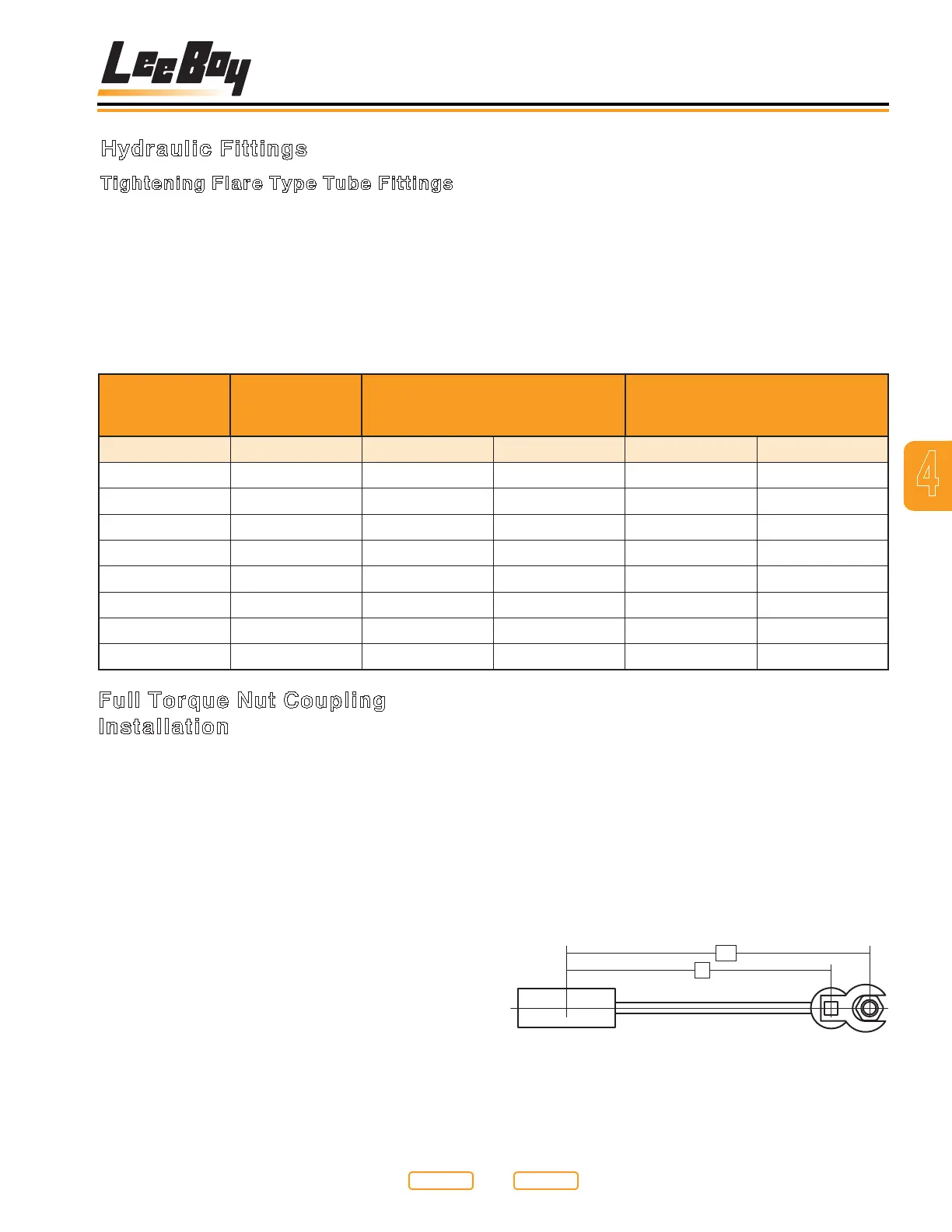

Full Torque Nut Coupling

Installation

The only completely reliable method of creating a

consistent leak free, long lasting connection is to ensure

that the coupling is brought to the proper torque.

The best method of ensuring a coupling is brought to the

proper torque is to use a torque wrench with crowfoot.

To ensure the proper torque is met, use the ats method

of torque verication. Flats method may be used alone

in situations where a torque wrench is inaccessible or

unavailable.

There are 7 steps involved in proper coupling installation:

1. Determine the correct torque value for your coupling.

NOTE: Only use the torque values specied from

the manufacturer, do not use SAE torque

recommendations.

The minimum torque values are adequate for

sealing in most applications, and the maximum

torque values should never be exceeded.

2. Calculate the correct torque wrench setting using

(see Equations in Section 4).

NOTE: The most straight forward method of determining

the correct torque setting is to multiply the

desired torque by the length of the wrench from

the center of the handle to the center of the drive

(L) divided by the length of the wrench from the

center of the handle to the crowfoot center (LA),

(Figure 4-2).

LA

L

Torque Wrench - Crowfoot

Figure 4-2

NOTE: Torque Wrench Setting = Desired Torque * L / LA

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...