7-12 LeeBoy Model 8510B Conveyor Paver

Maintenance

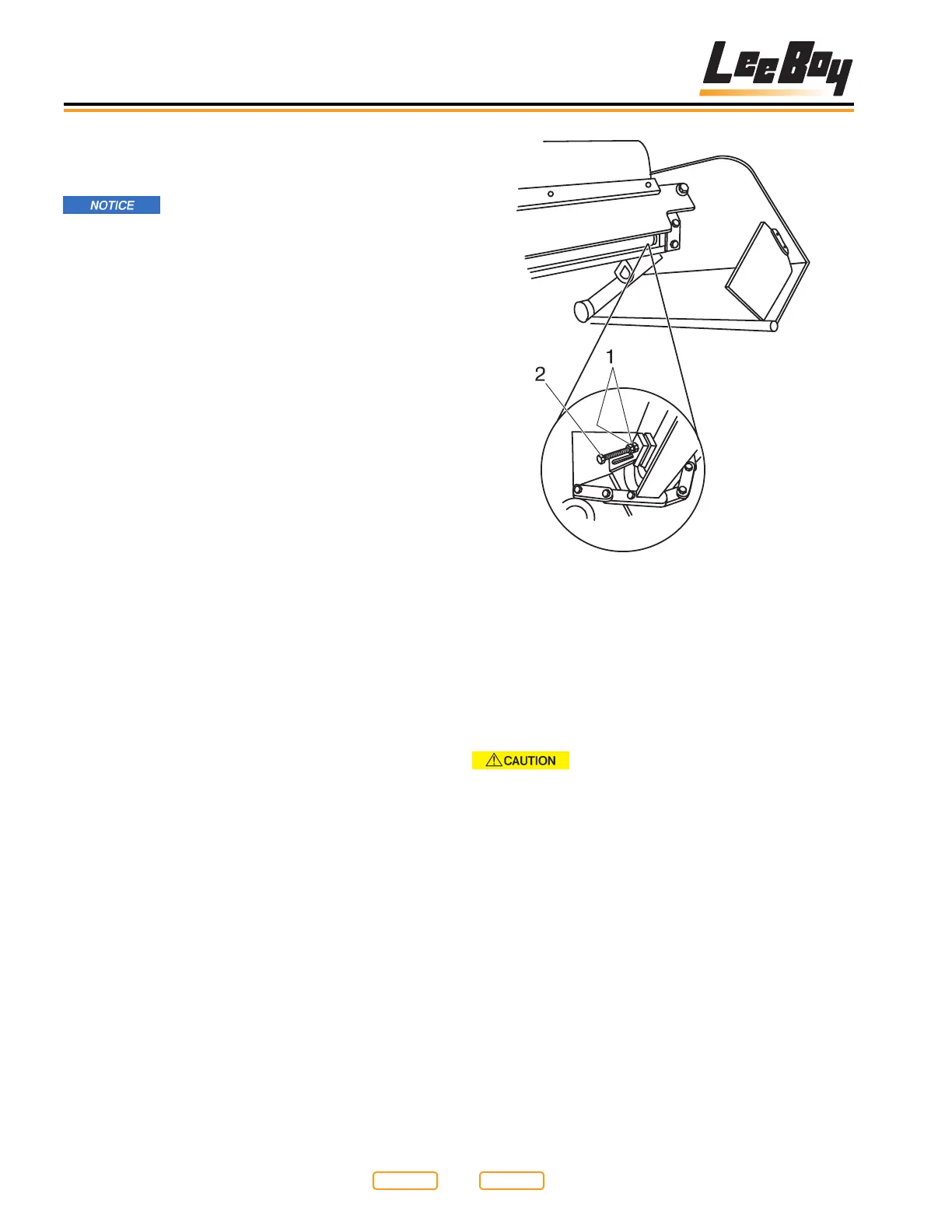

Adjusting Bolt

Figure 7-9

1 - Locknut

2 - Adjustment Bolt

Automatic Track Adjustment

NOTE: Failure to maintain adequate throttle setting may

cause improper adjustment to track.

When backing this paver with load,

maintain at least a three-quarter throttle setting.

Failure to do so may cause improper track tension,

resulting in poor performance and damage.

Hydraulic adjustment cylinders are automatic and

provide even tension on track that prevents excessive

wear to paver undercarriage. This feature requires the

operator, when backing with load, to maintain at least

three-quarter throttle setting. Hydraulic pressure below

three-quarter throttle is not adequate to maintain track

adjustment.

Conveyor Flight Chain

Adjustment

For cold weather, keep conveyor ight

chain properly oiled with cleaning solvent or release

agent. This will prevent conveyor from sticking inside

of conveyor pan. Neglect could result in conveyor

bars bowing if conveyor sticks.

NOTE: The conveyor should run smooth when conveyor

chain is properly adjusted. These chains should

be adjusted every 100 hours to maintain smooth

operations. If irregular movement of the conveyor

occurs, this is generally a sign that an adjustment

is needed.

Use the following procedure to make adjustment:

1. Raise conveyors (see Raising Conveyor in Section

7). Put keys in safe place.

2. Secure safety prop (Figure 7-8,1) to prevent

conveyor from accidentally lowering.

3. Loosen the locknut (Figure 7-9,1) and bolt holding

the Adjustment Roller Assembly.

4. Turn adjustment bolts (Figure 7-9,2) alternately on

both sides of the conveyor. (LeeBoy recommends

turning one bolt one half turn, then the other bolt

one half turn. Continue alternating tightening until

chains have 3/4” to 1 1/4” slack on top when lifted off

conveyor deck). The pressure on the chain will be

noticeable as the bolts are tightened.

5. After the conveyor chain tension is set, tighten

locknut (Figure 7-9,1) and bolt holding assembly.

6. If the adjustment bolts (Figure 7-9,2) have been

run out, it will be necessary to remove a link in the

conveyor chains and add a half link. This repair

should bring the adjustment bolts back to full travel.

7. Repeat steps 1 through 4 for the opposite side.

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...