7-8 LeeBoy Model 8510B Conveyor Paver

Maintenance

100-Hour or Monthly Routine

Maintenance

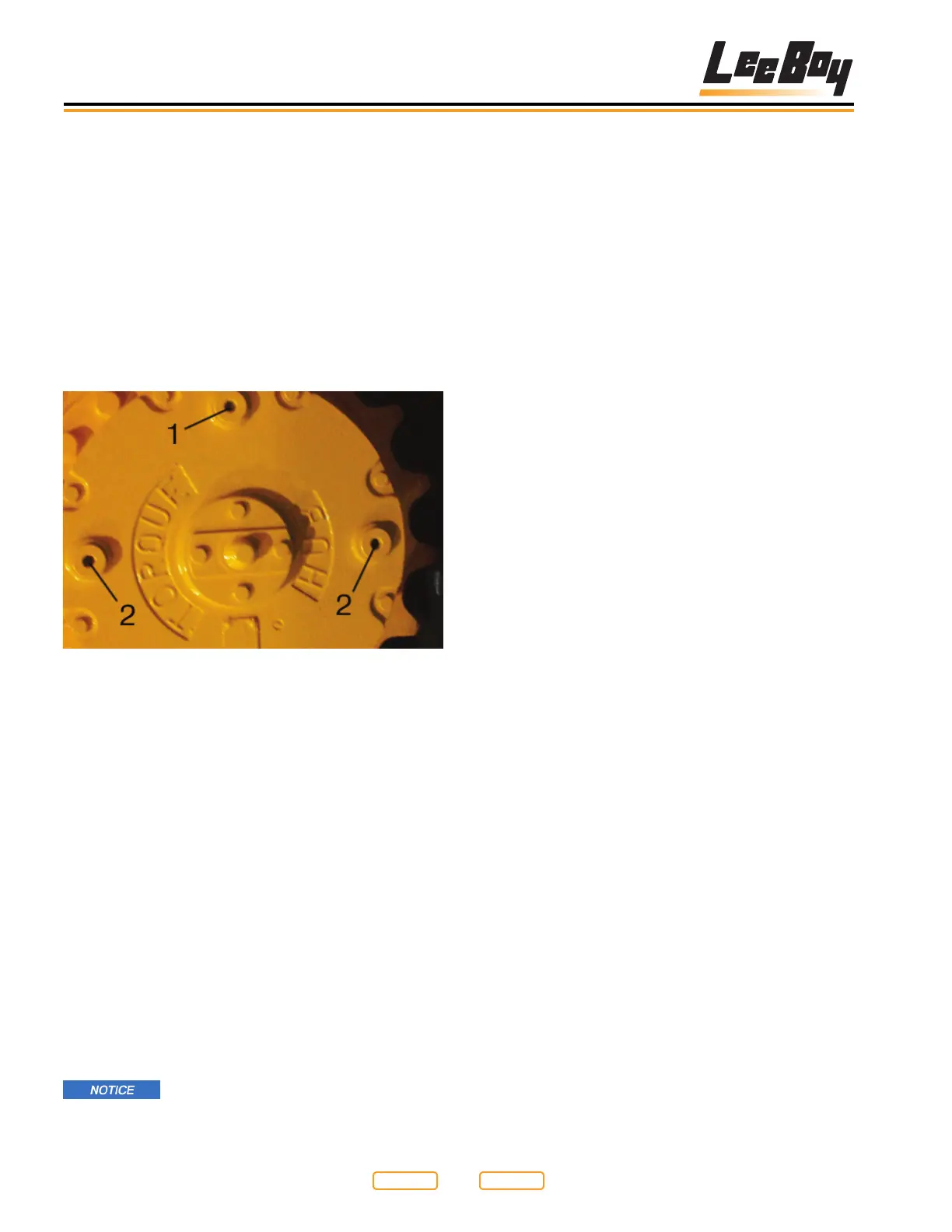

1. Position the torque hub so the center plug (Figure

7-3,1) is at the twelve o’clock position. Remove

the plug either at the three or nine o’clock position

(Figure 7-3,2). If oil comes out, no oil is needed.

Insert plug and tighten. If oil does not come

out, remove the plug at the 12 o’clock position

and ll torque hub with specied gear oil (see

Specications in Section 4) until oil starts to appear

at the other hole. Replace both plugs and repeat

process on other torque hub.

Torque Hub Plug Orientation

Figure 7-3

1 - Center Plug

2 - Side Plugs

2. Perform any other engine preventive maintenance

as described in the engine operator’s manual.

3. Check and adjust all chains, as required (see

Conveyor Drive Chain Adjustment in Section 7).

250-Hour or Quarterly Routine

Maintenance

1. Perform the 250-hour preventive maintenance as

described in the engine operator’s manual.

2. Change charge lter between valve bank and main

pump.

3. Change return lter on hydraulic tank.

4. Check air cleaner, if the engine is equipped with a

dry type element.

Improperly serviced air cleaners

quickly wear out engines and piston rings.

500-Hour or Semi-Annual

Routine Maintenance

1. All bearings are sealed and have grease ttings.

These should be greased with multipurpose grease

using a hand grease gun. Be careful to avoid

blowing the seals.

2. Perform the 500-hour preventive maintenance as

described in the engine operator’s manual.

3. Replace dry type air lter, if equipped. Refer to

the current engine operator’s manual for service

information.

4. Change engine oil. To assure complete removal of

contaminants in the oil, perform the oil change while

engine is warm.

5. After draining used oil, clean and reinstall

drain plug and ll crankcase to the full mark

with manufacturer’s recommended oil (see

Specications in Section 4).

6. Change engine oil and lters.

NOTE: For your convenience there is an oil drain hose

located inside of the right-hand side cover on the

paver. The hose is accessible without removing

cover, stick hose through hole in side.

7. Change oil in conveyor torque hubs, (see

Specications in Section 4).

8. Change oil in drive torque hubs, (see Specications

in Section 4).

1000-Hour or Annual Routine

Maintenance

1. Drain and ush the hydraulic tank. A drain plug is

located on the bottom of the tank for this purpose.

Fill as required (see Changing Hydraulic Oil in

Section 7).

2. Perform the 1000-hour preventive maintenance as

described in the engine operator’s manual.

3. Change oil in conveyor torque hubs, (see

Specications in Section 4).

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...