7

LeeBoy Model 8510B Conveyor Paver 7-15

Maintenance

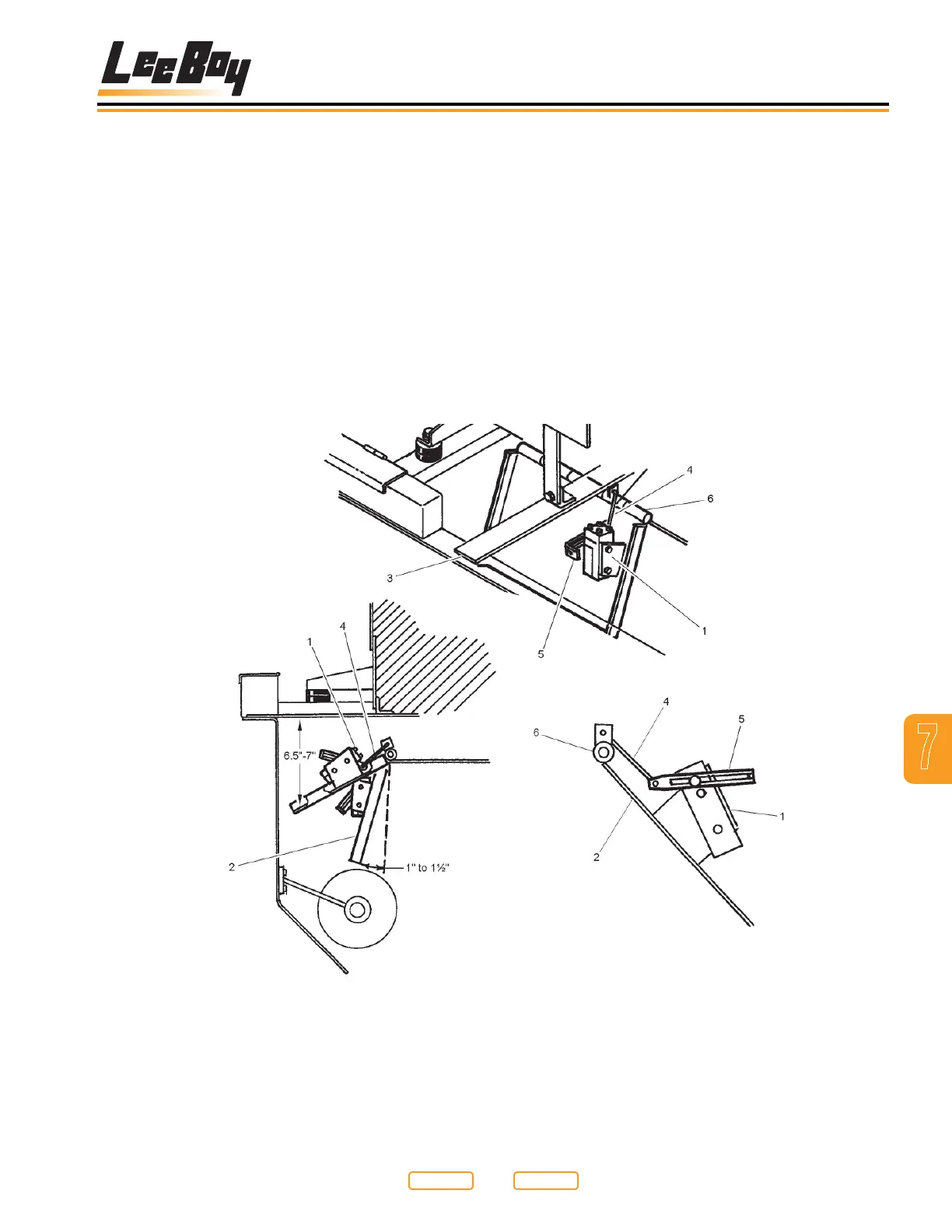

Conveyor Limit Switch

Adjustment

In order for the conveyor’s start and stop to occur at the

correct position, small adjustments may be necessary

to the micro-switch (Figure 7-12,1) located on the

conveyor ap (Figure 7-12,2). There are two positions

of the conveyor ap: one upper, shutting the conveyor

OFF, and one lower, turning the conveyor ON. Read the

following procedures carefully, referring to the gures

as needed.

1. Raise the conveyor ap (Figure 7-12,2) 6-1/2 to 7

in. (16.5 to 17.8 cm) from bottom of the tank mount

support (Figure 7-12,3). Secure conveyor ap so

Conveyor Micro-Switch Location

Figure 7-12

it remains in this position. If micro-switch clicked

OFF within the 6 1/2 to 7 in. (16.5 to 17.8 cm) limit, no

further adjustment is required to the upper travel.

2. If the micro-switch (Figure 7-12,2) did not click OFF,

adjustment is needed. Remove the linkage (Figure

7-12,4) attaching the actuator arm (Figure 7-12,5)

to the eyelet on the ap pivot housing (Figure

7-12,6).

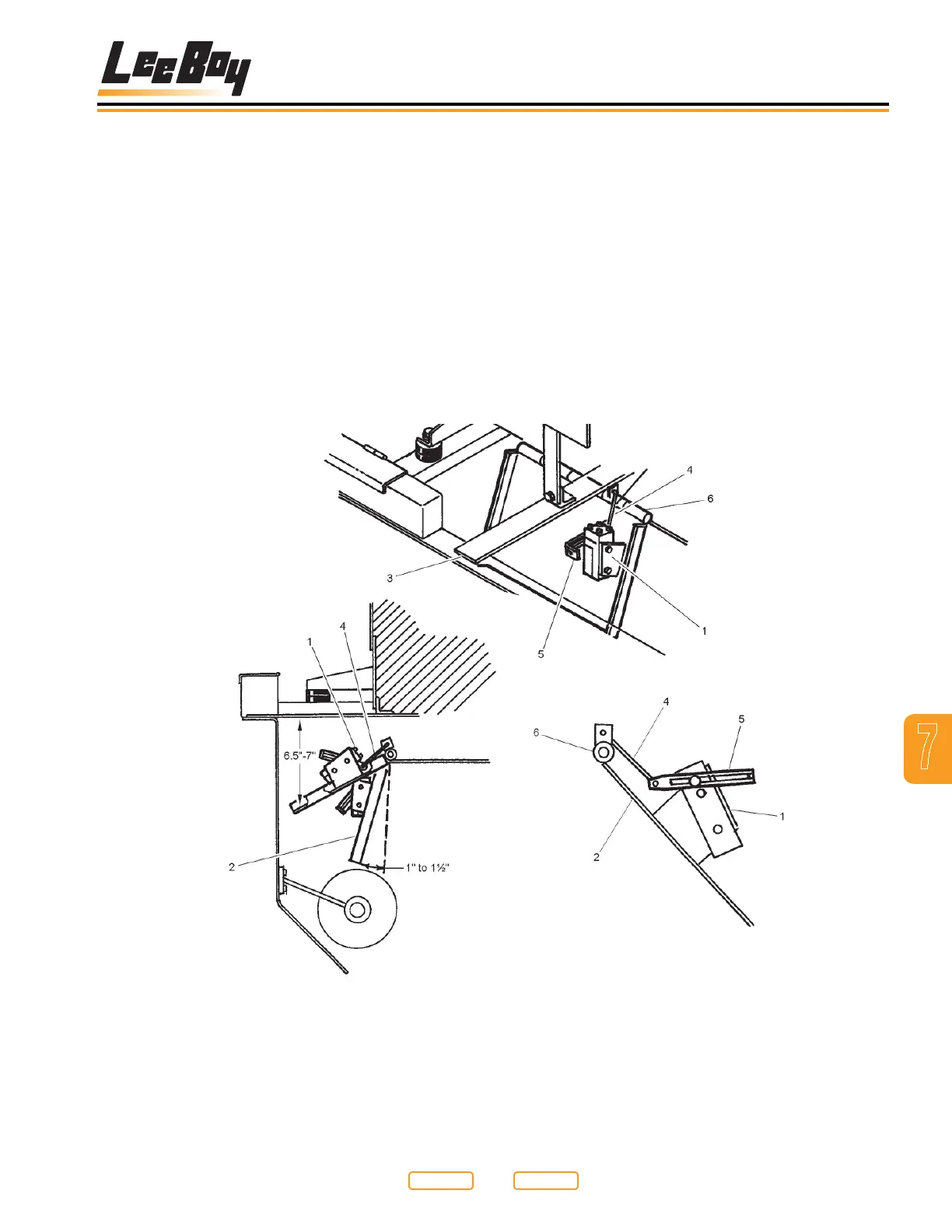

3. Loosen setscrew “A” (Figure 7-13,1), on the

actuator arm (Figure 7-13,2). Reposition this arm

by either rotating it clockwise or counterclockwise

depending where the micro-switch clicked OFF

during the conveyor aps upward travel (see Figure

7-13).

1 - Microswitch

2 - Conveyor Flap

3 - Tank Mount Support

4 - Linkage

5 - Actuator Arm

6 - Flap Pivot Housing

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...