6

LeeBoy Model 8510B Conveyor Paver 6-13

Operation

• Set the screed directly on a fresh mat of hot asphalt

while running the heating system, allowing the heat of

the asphalt to help heat the screed plate.

Starting To Pave

The LeeBoy Model 8510B Conveyor Paver is capable of

placing bituminous base, binder and surface courses,

lime or Portland cement stabilized sub-base and graded

aggregate materials up to a thickness of 6 in (20 cm).

The paver has a production rate of approximately 250

tons per hour.

The paver is equipped with electric and manual

thickness controls and an 8 ft to 15 ft (2.8 m to 4.5 m)

wide screed. The paver can handle everything such as

driveways and small parking lots to large parking areas

and secondary roads.

Before starting to pave, keep the following points in

mind:

1. Plan the project so that the narrowest passes are

rst, (the basic width of the paver) leaving the widest

pass until last.

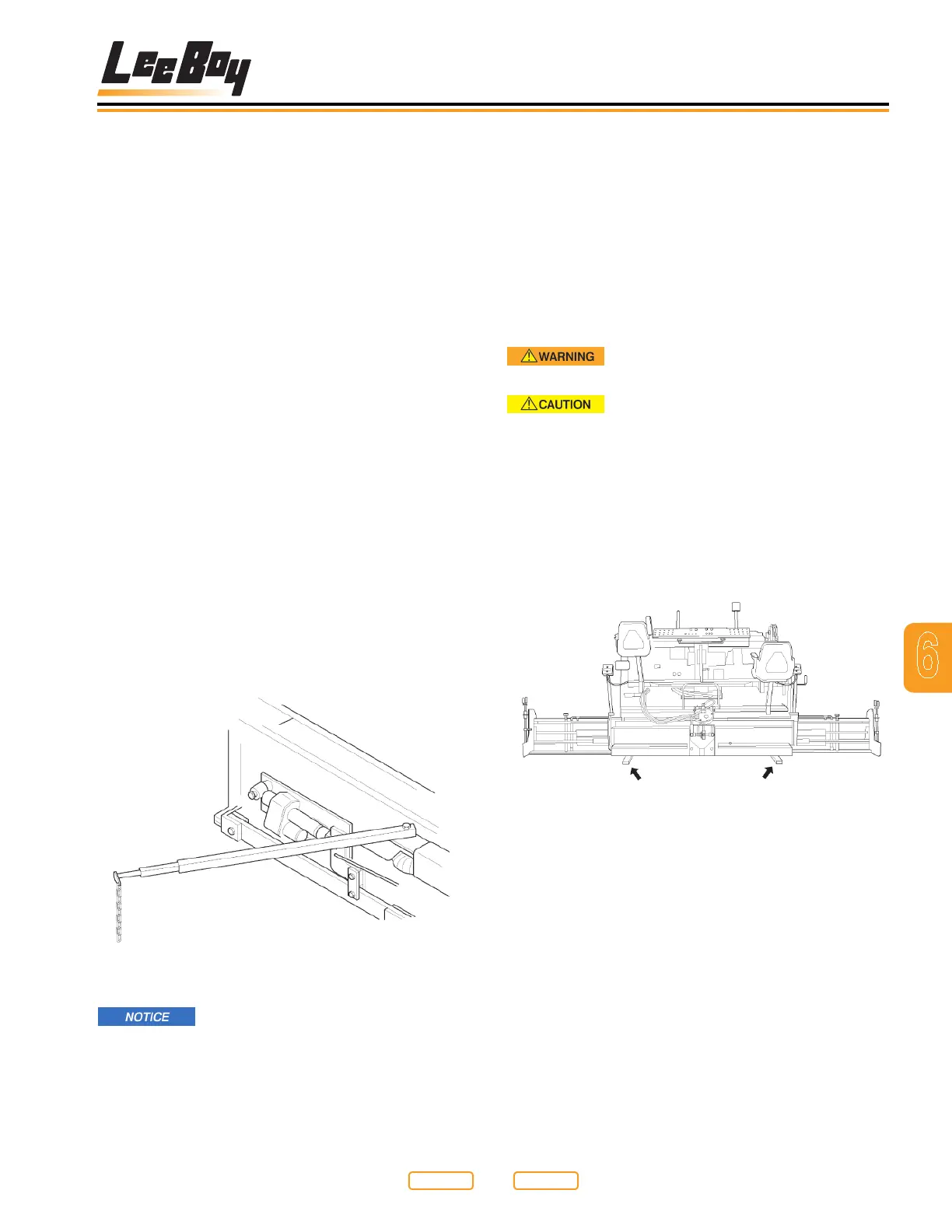

2. Make sure to use a reference guideline. This can

be a curb, gutter, adjacent mat or a string line. It is

important that the rst pass be straight. It will be the

guideline for the following passes. Use the guide bar

gauges as shown in Figure 6-9.

Guide Bar Gauges

Figure 6-9

Never run the paver through a pile of

mix that has been dumped in front of the paver. Not

only will this effect the level of the mat being laid but

damage may result.

3. It is the operator’s responsibility to guide the truck

up to the paver and signal the driver when and how

much to dump into the hopper. Truck drivers must

maintain a light pressure on truck brakes to keep

truck from dumping material on the roadway.

NOTE: If the paver is equipped with a truck hitch, the

truck driver will not be required to maintain

pressure on the brake (see Truck Hitch

Attachment (Option) in Section 6).

4. Always pave in low range.

Before starting forward with paver

make certain that no one is in front of the paver.

Avoid low hanging limbs, power lines,

and other foreign objects that can endanger crew or

paver.

Setting Screed To Pave

1. Move to the starting position.

2. Extend the screed to the desired width.

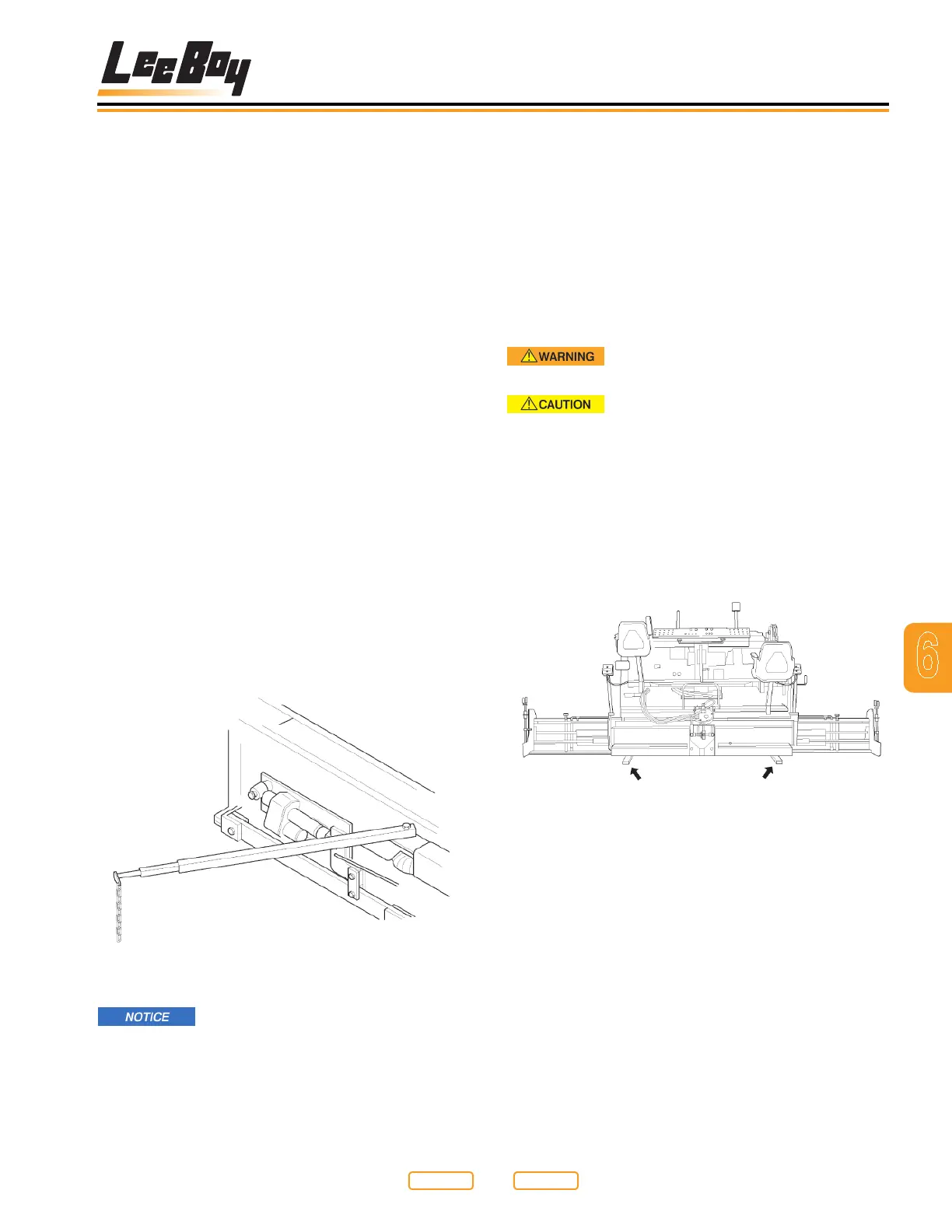

3. To set depth, place screed on starter blocks

(Figure 6-10).

Starter Blocks

Figure 6-10

4. Level screed with ight screws (Figure 5-6,2) until

neutral position is felt.

NOTE: Neutral position is when the pressure on the

ight screw is the same when screwing either

clockwise or counterclockwise.

5. Set the left or right SCREED LIFT lever to the FLOAT

position. This will remove the hydraulic pressure

from the cylinder, allowing screed to oat.

6. Turn ight screw about one complete turn

clockwise.

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...