7

LeeBoy Model 8510B Conveyor Paver 7-13

Maintenance

Conveyor Drive Chain

Adjustment

Entanglement Hazard! Do not run

engine while checking and servicing conveyor drive

train.

1. Look at drive chain through the top of the frame.

If drive chain has excessive loose motion in it,

adjustment is necessary.

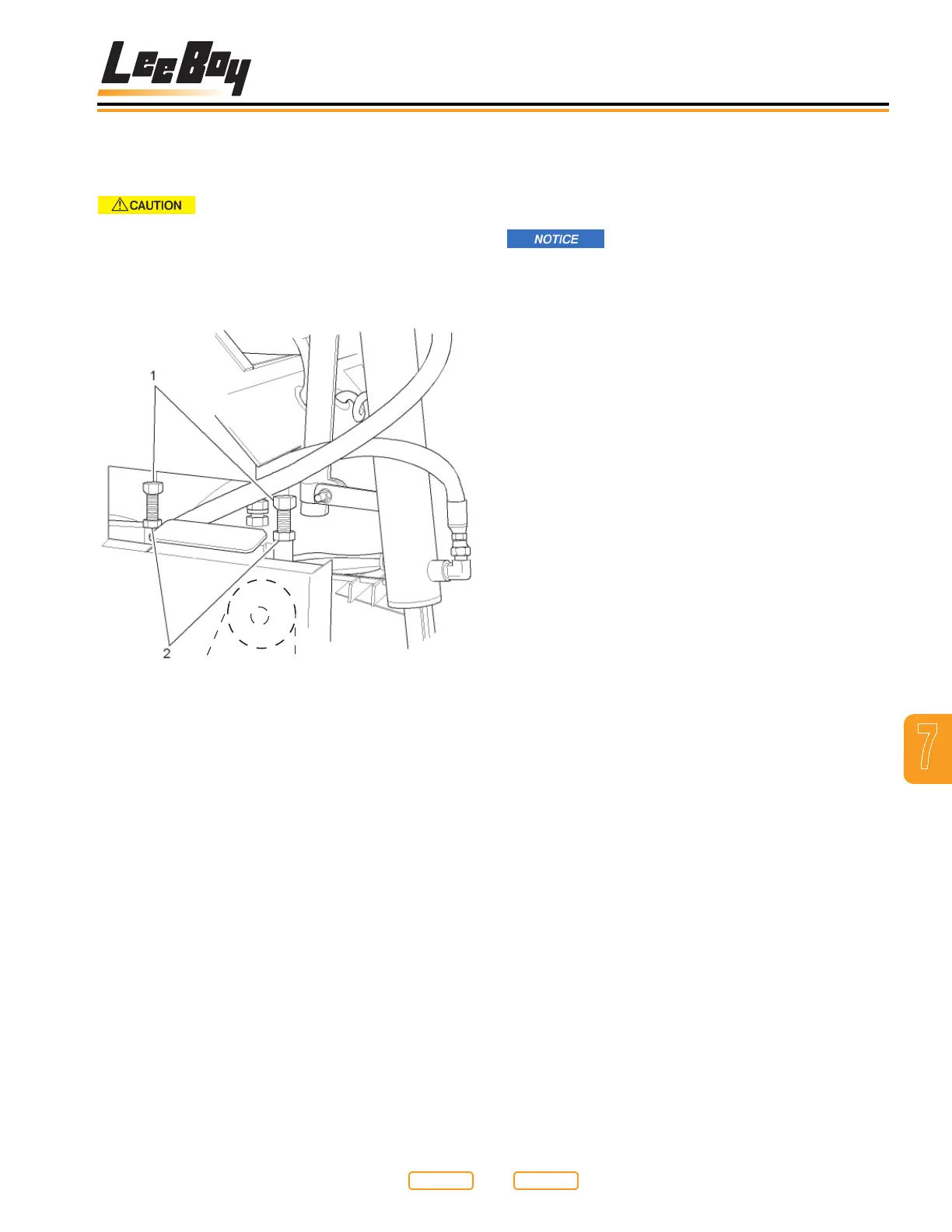

Conveyor Chain Adjusting Bolts

Figure 7-10

1 - Chain Adjuster

2 - Locknut

2. If adjustment is necessary, continue to operate

conveyors at fast speed and loosen the locknuts

(Figure 7-10,2) on the chain adjuster. Turn the

chain adjuster (Figure 7-10,1) until the whip in the

drive chain disappears.

3. Retighten locknuts (Figure 7-10,2) when

adjustment is made.

4. Perform the same check on the opposite conveyor

drive chain.

Torque Hub Hydraulic Motor

Adjustment

Low Gear

Torque hub hydraulic motors are

calibrated and set at the factory. Only an Authorized

LeeBoy Dealer should make adjustments.

NOTE: The low gear adjustment screw is located on

bottom of drive motor.

The adjustment must be made to the slow side drive

motor only. Only make small changes at a time and

recheck paver. Proceed as follows:

NOTE: Low gear operation requires each HIGH/LOW

switch on both sides of the dash panel to be in

the LOW position.

5. Raise conveyor (see Raising Conveyor in section

7).

6. With paver running, set the HIGH/LOW switches to

the LOW position.

7. Locate adjustment screw on the bottom of the

hydraulic motor.

8. Adjust screw in small increments of about 1/4 turn

then recheck tracking.

High Gear

NOTE: The high gear adjustment screw is located on top

of drive motor.

Tracking adjustment on the high side gear is performed

by adjusting the screw on top of hydraulic motor. The

adjustment on the motor for the fast track must be

screwed in to equalize track speed.

NOTE: If hydraulic motor has not been previously set,

ten revolutions of the adjustment screw may be

required before noticing any difference in travel.

NOTE: High gear operation requires each HIGH/LOW

switch on both sides of the dash panel to be in

the HIGH position.

1. With paver running, set the HIGH/LOW switch to the

HIGH position.

2. Adjust screw on top of hydraulic motor until back

pressure from spool is felt on adjustment screw.

This indicates adjustment is close.

3. Finalize adjustment by making one quarter (1/4) turn

at a time until correct adjustment is made.

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...