7-16 LeeBoy Model 8510B Conveyor Paver

Maintenance

Electrical System

Use compressed air to blow dirt from

generator monthly or more often if used in dirty

environment. Do not use high pressure water.

Always make sure work area is clean

and free of any water before working on electrical

system.

Generator Voltage Testing

The LeeBoy Model Legend Electric Screed System

generator is hydraulically driven. When the paver

engine is at full rpm and the hydraulic system at normal

operating temperature, the generator should produce

between 220VAC and 240VAC.

The voltage of the generator depends on speed

(rpm). The voltage increases as rpm increases, and

decreases as rpm decreases. The voltage will decrease

signicantly if generator speed is slower than 3000 rpm.

NOTE: When testing the generator voltage ensure the

paver engine is at full rpm and the hydraulic

temperature is at normal operating levels.

To test the generator voltage at the generator:

1. Use volt meter to measure between the two main

input wires L1 and L2 (Figure 7-15,2,3). If you

measure from L1 to the frame of the paver, or

ground, the voltage will be half of the rated output of

the generator. The voltage should be the same as

measured at the control box.

To test the generator voltage at the control box:

1. Use volt meter to measure between the two main

black and white input wires located inside the

control box on the terminal block similar to one in

Figure 7-15. The voltage should be the same as

measured at the generator.

NOTE: If your voltage at this point is lower, make certain

the generator is turning the correct speed (see

Generator Speed Tuning in Section 7).

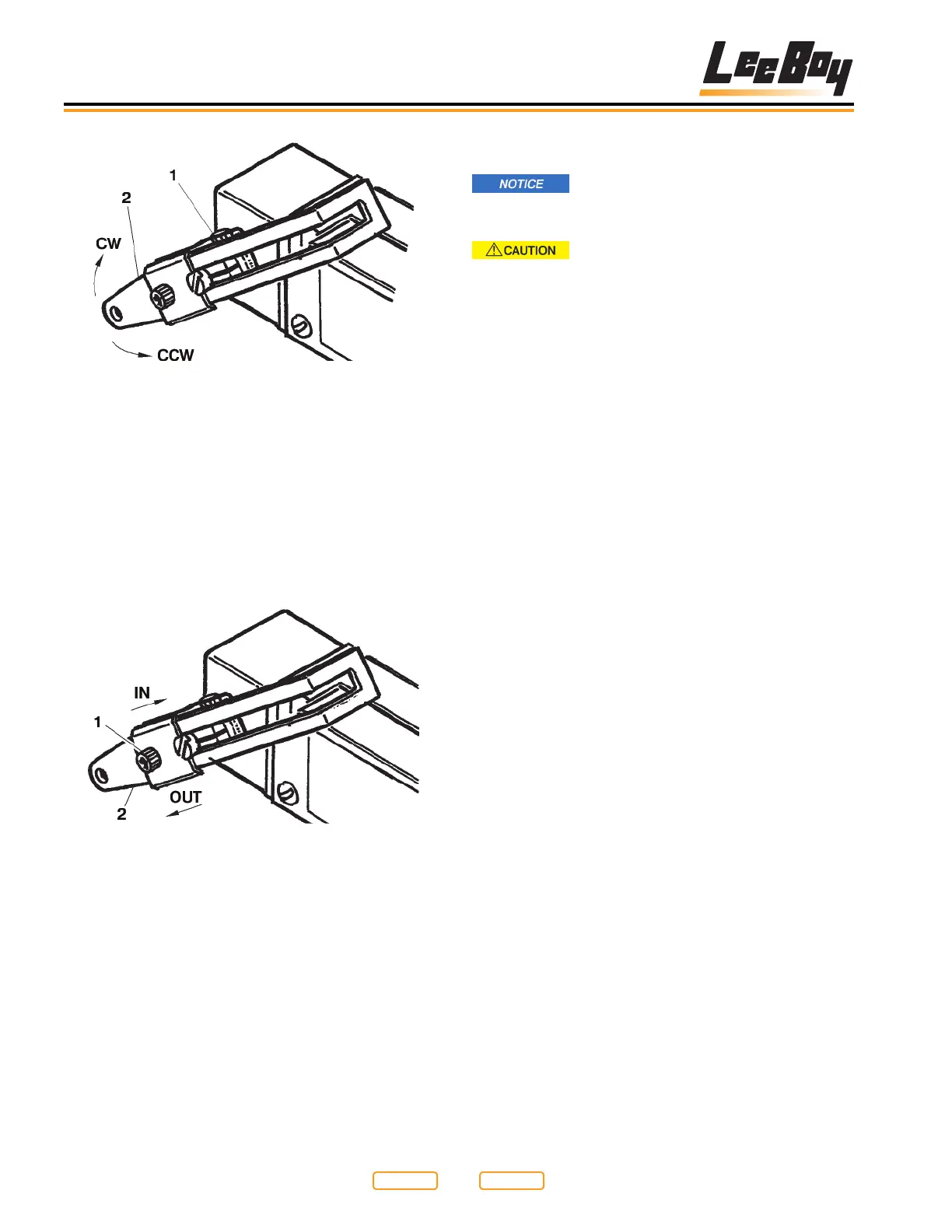

Setscrew “A” Location

Figure 7-13

1 - Setscrew A

2- Actuator Arm

4. When the click OFF occurs between the 6-1/2 to

7 in. (16.5 to 17.8 cm) limit, tighten setscrew and

connect linkage.

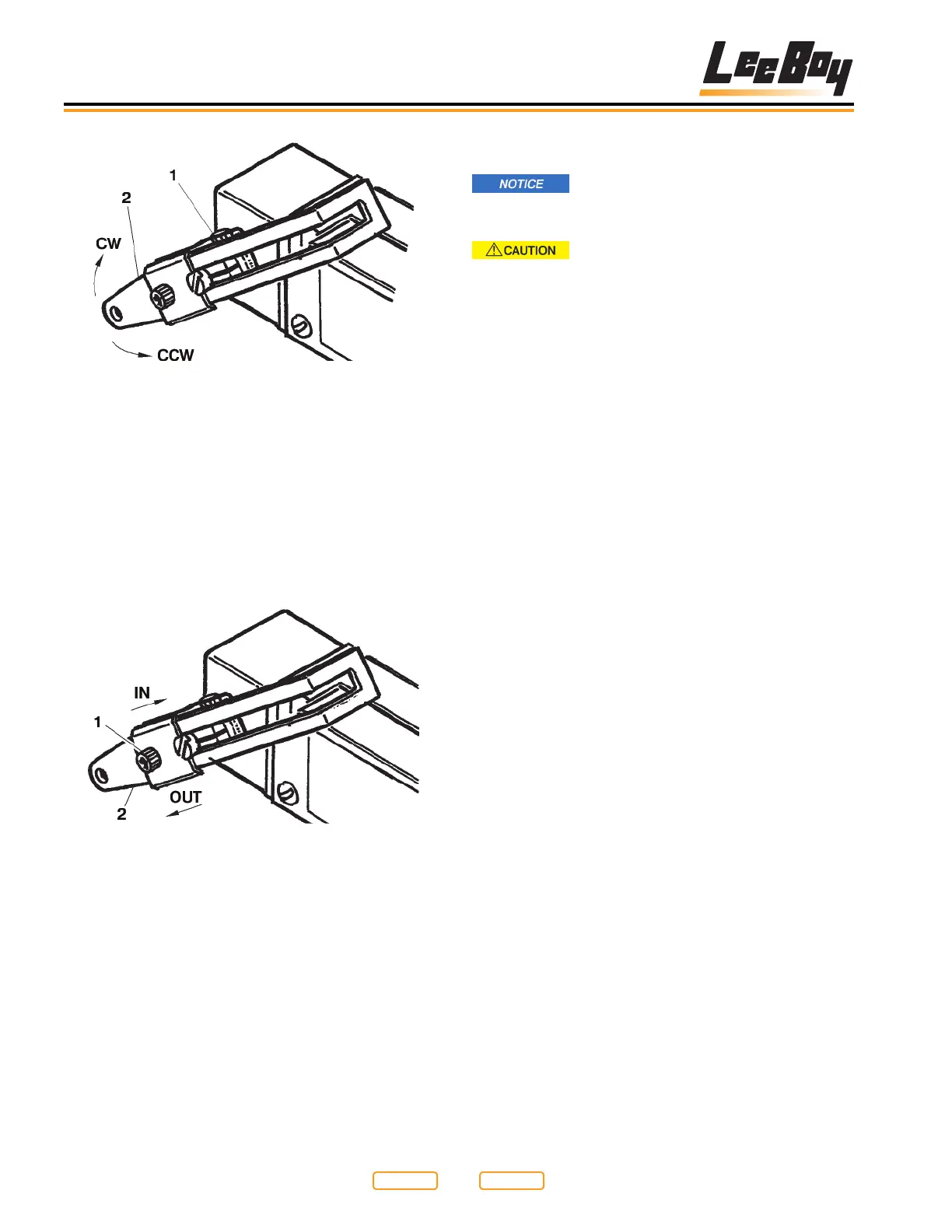

5. If the lower ap travel does not fall into the lower

limits, loosen setscrew “B” (Figure 7-14,1) on the

actuator arm (Figure 7-14,2) slightly.

Setscrew “B” Location

Figure 7-14

1 - Setscrew B

2 - Actuator Arm

NOTE: The setting from the factory is 1 in. (2.54 cm) from

the center of the setscrew “B” to the eyelet on

the actuator arm.

6. To bring the travel limits into tolerance, slide the

actuator arm in the direction desired. This may

require several adjustments before the correct

position is obtained. When the actuator arm is in the

correct position, tighten setscrew “B”. No further

adjustment is necessary.

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...