7

LeeBoy Model 8510B Conveyor Paver 7-5

Maintenance

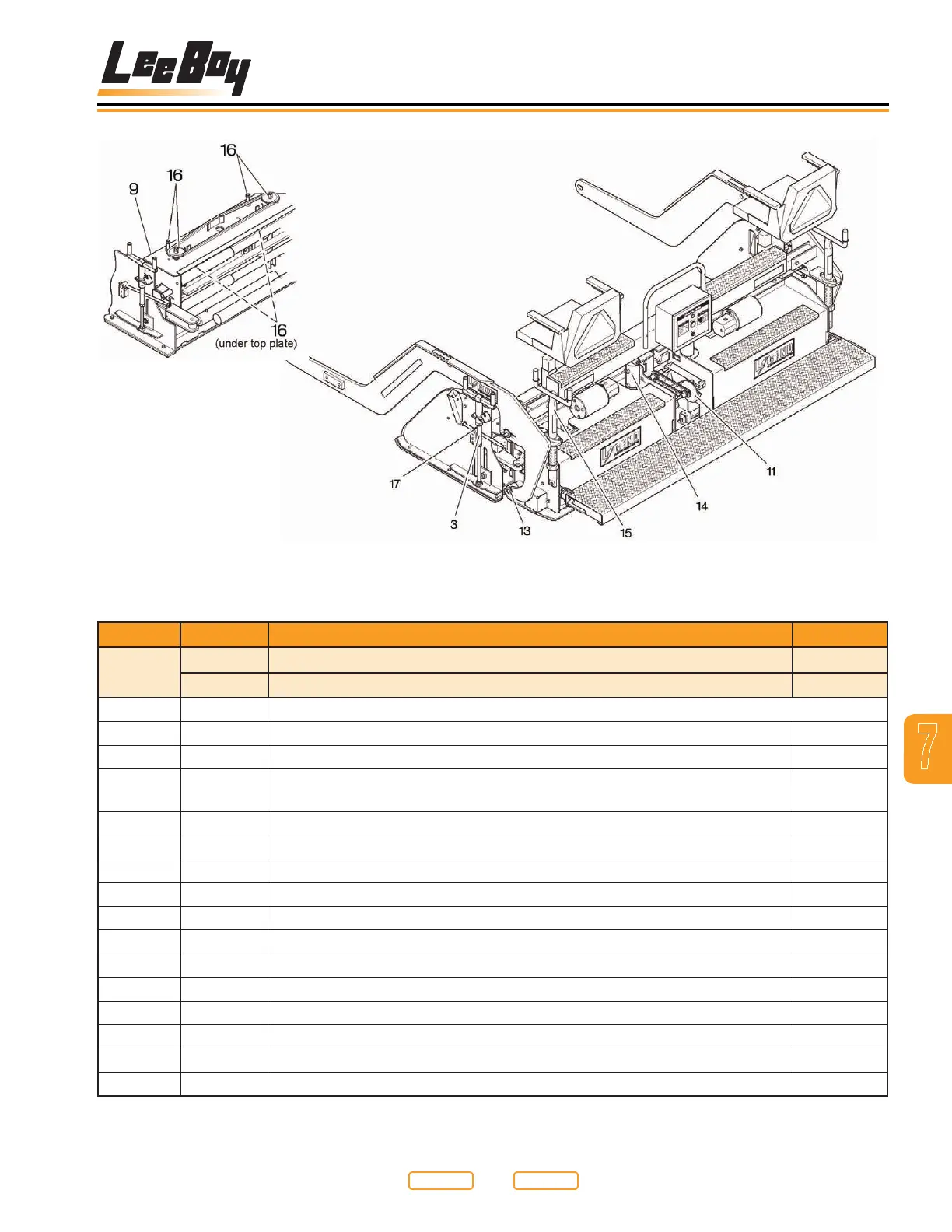

Lubrication Points

Figure 7-2

Table 7-2. Lubrication Points Schedule

ITEM NO. TYPE LUB DESCRIPTION AND LOCATION INTERVAL

Legend

A Grease With Shell Avania EP Grease 2 Or Equivalent

B Spray With An Approved Release Agent

1 A Auger, grease tting on end mount (end of day) Daily

2 A Conveyor Pivot, front of screed each side under conveyor deck Weekly

3 A Depth Screw (grease rst in lock position, unlock and turn 180° and grease) Weekly

4 A Flange Bearing and Fitting, on ight screw plus ange bearing, on T-handle

of extension, (both sides)

Weekly

5 A Pillar Block bearing, on rear axle 3 Months

6 B Conveyor and Auger, as shown Daily

7 B Auger Chain, middle of paver Daily

8 B Paver, clean all surfaces Daily

9 B Tracks, between track pads Daily

10 B Screed Crown, on chain Weekly

11 B Spray any part of paver that contacts asphalt Daily

12 A Screed Pivot Weekly

13 A Slope Cylinder Pivot Weekly

14 A Main Flight Screws Ball Socket & Nut Weekly

15 A All Screws On Extension And Bearing Weekly

16 A Tilt Screws Weekly

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...