Overload Safety Devices

56

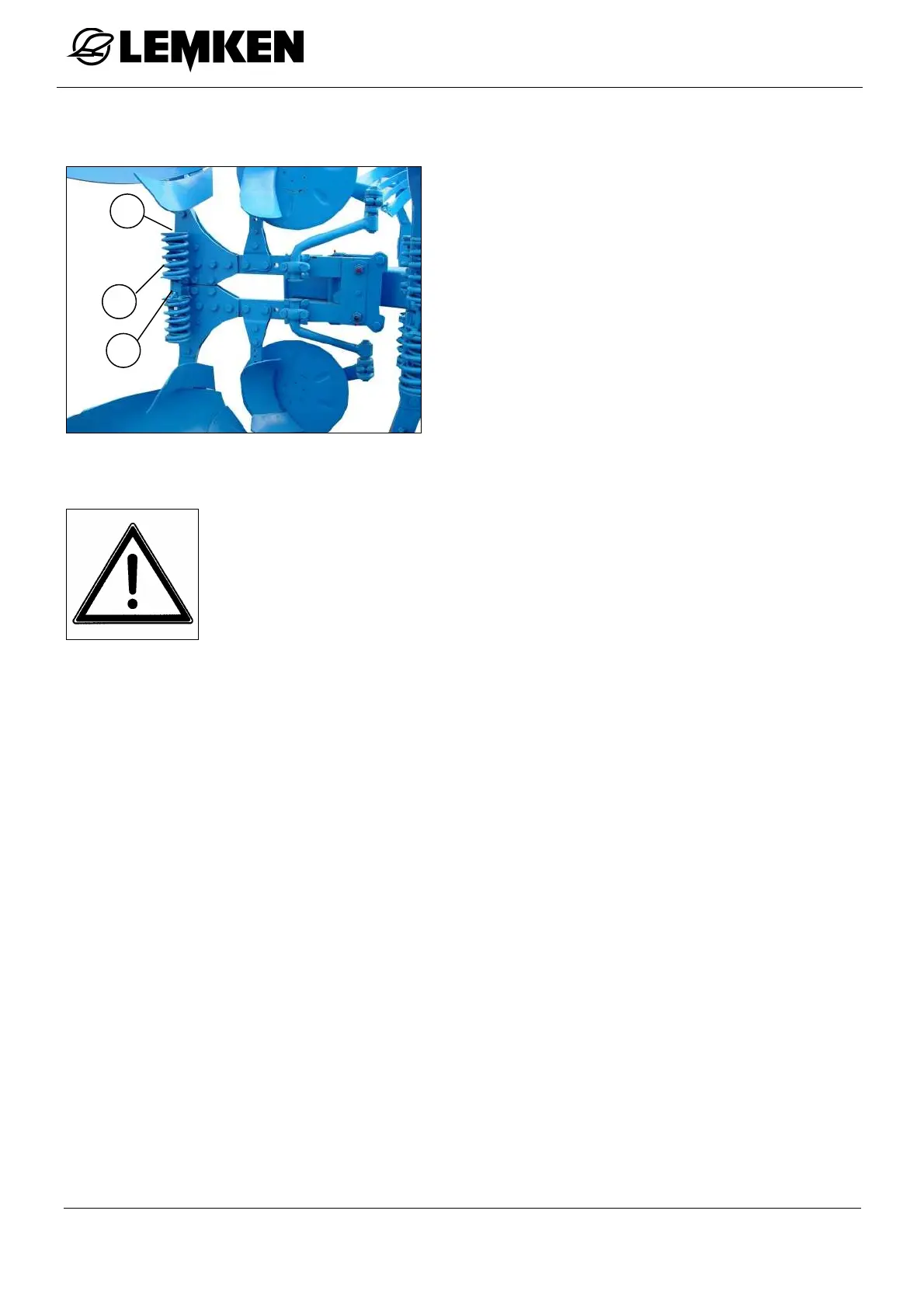

9.3 Automatic Non-Stop Overload Safety Device

The overload safety device is set at the

factory for average conditions.

Should the mechanism still trip without

touching an obstacle, the tripping force of

the overload safety device must be in-

creased. Therefore turn screws (1) clock-

wise.

It is essential that all springs (2) are ad-

justed equally to ensure a troublefree func-

tion of the overload safety device.

• Do not allow any body within the trip area of the bodies.

• With an overload, the bodies trip upwards. Keep distance!

• Springs are under high spring tension!

• Damaged draw rods (3) must be replaced at once!

9.4 Hydraulic Non-Stop Overload Safety Device “HydriX“

With the hydraulic adjustable overload safety device two fix operation pressures

can be adjusted, a minimum operation pressure, i.e. for shallow ground and light

soil conditions, and a maximum operation pressure, i.e. for heavy soil conditions

1

2

3

Loading...

Loading...