Page 89 of 295

Input/output specifications: dual Hall positioning

Dual Hall digital (F3) with power switch

Item Specification Comment

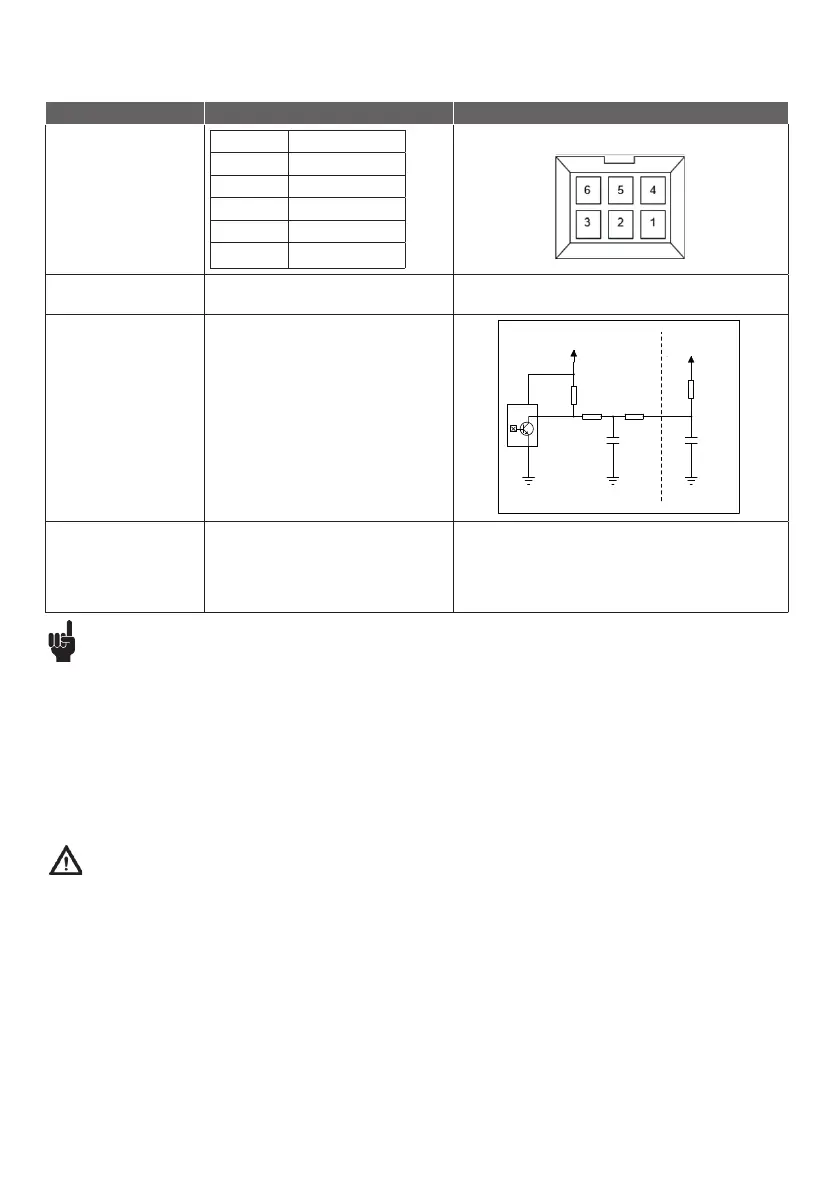

Pin

configuration

Pin 1 GND

Pin 2 VCC

Pin 3 M+

Pin 4 HALL A

Pin 5 HALL B

Pin 6 M-

Connector in LC1 housing

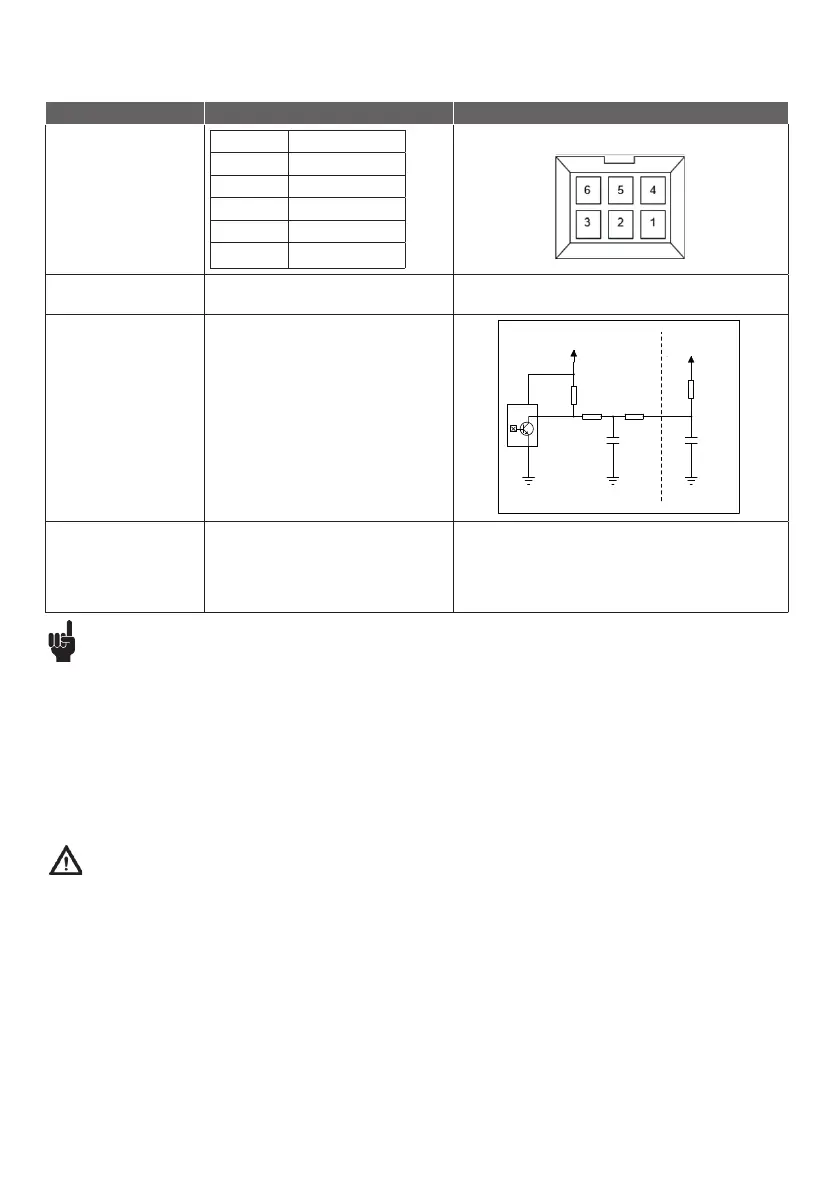

VCC 4-15V

Current Maximum 15 mA @ 10 kΩ and 1 nF load.

See diagram.

Resolution Number of dual Hall state shifts/spindle turn:

N = 108 state/turn:

6 mm spindle: 12/108

10 mm spindle: 20/108

s

DRAWING NO:

LTR

CODE:

SIZE:

C

B

A

C

D

6 5 4 3 2 1

DATE:

D

B

A

TITLE:

COMP ANY :

RELEASED:

DATED:

DATED:

QUALITY CONTROL:

CHECKED:

DATED:

DATED:

DRAWN:

ECO NO:

APPROVED:

REVISION RECORD

SHEET: OF

SCALE :

LINAK A/S

LAxx / LCxx

Dual-Hall feedback

HALL OUTPUT

EXT. LOAD

100R

100 nF

100R

10K 1%

PWR

GND

10K 1%

1nF

VCC

VCC

Recommendations

Warnings

• Always follow the important LC1 mounting guidelines and LINAK specifications to ensure correct functionality.

• LC1 is for use in push applications, cable outlet from (smallest profile) top plate. See top plate dimensions.

• Always use LINAK compatible components and ensure that the application functionality is tested with all accessories connected

before bringing it into service.

• The mounting plate in the application must cover the entire LC1 top plate and be strong enough to carry the load.

• Regular cleaning is recommended to reduce bacteria and increase the hygiene level. Do not use chemicals for cleaning.

• The LC1 is intended for indoor use and NOT for use in harsh environments, like for instance pool or marine environments

and agriculture buildings with ammonia vapors.

• Assure free space for movement of application in both directions to avoid blockade.

• Do not expose the column to high intensity ultraviolet radiation disinfection lamps as this may damage supporting parts and cables.

• The LC1 is heavy and weighs 9.0 kg. To avoid personal injury, DO NOT DROP!

• Always use cable lock to ensure fixation of cables and take care that the cable cannot be squeezed, pulled or subjected to any other stress or damage.

• Make a proper cable installation and inspect regularly for wear, damage and jarring sound to avoid cable interruption and actuator defects.

Defective parts must be replaced.

• A damaged housing can cause moisture to gather and lead to dangerous electrical connections between metal parts and wires.

• Always check correct assembly after mounting and service to ensure that the cable locks are mounted.

• Take special precaution concerning third party interfacing. Please contact LINAK for further information.

• Do not exceed the max. pull load specified on the label.

• Do not add dynamic load when changing between pull and push.

• Do not adjust anything during movement or while connected to mains as this may cause personal injury.

• Interconnecting cables must remain plugged in during cleaning to prevent the ingress of water.

• Mount with bottom plate downwards to obtain IPX4.

• After service inspection, the application must be tested for correct functionality before it is brought into operation to avoid misalignment

between two columns moving in parallel.

• LINAK recommends to make regular measurements of Class 1 protective ground conductivity in the application to avoid a disconnected

grounding cable. If there are worn-out or defective parts, the complete LC1 column must be replaced.

Loading...

Loading...