32

32

The GS550 System

The GS550 System

2.14

2.14

Slew Sensor Installation

Slew Sensor Installation

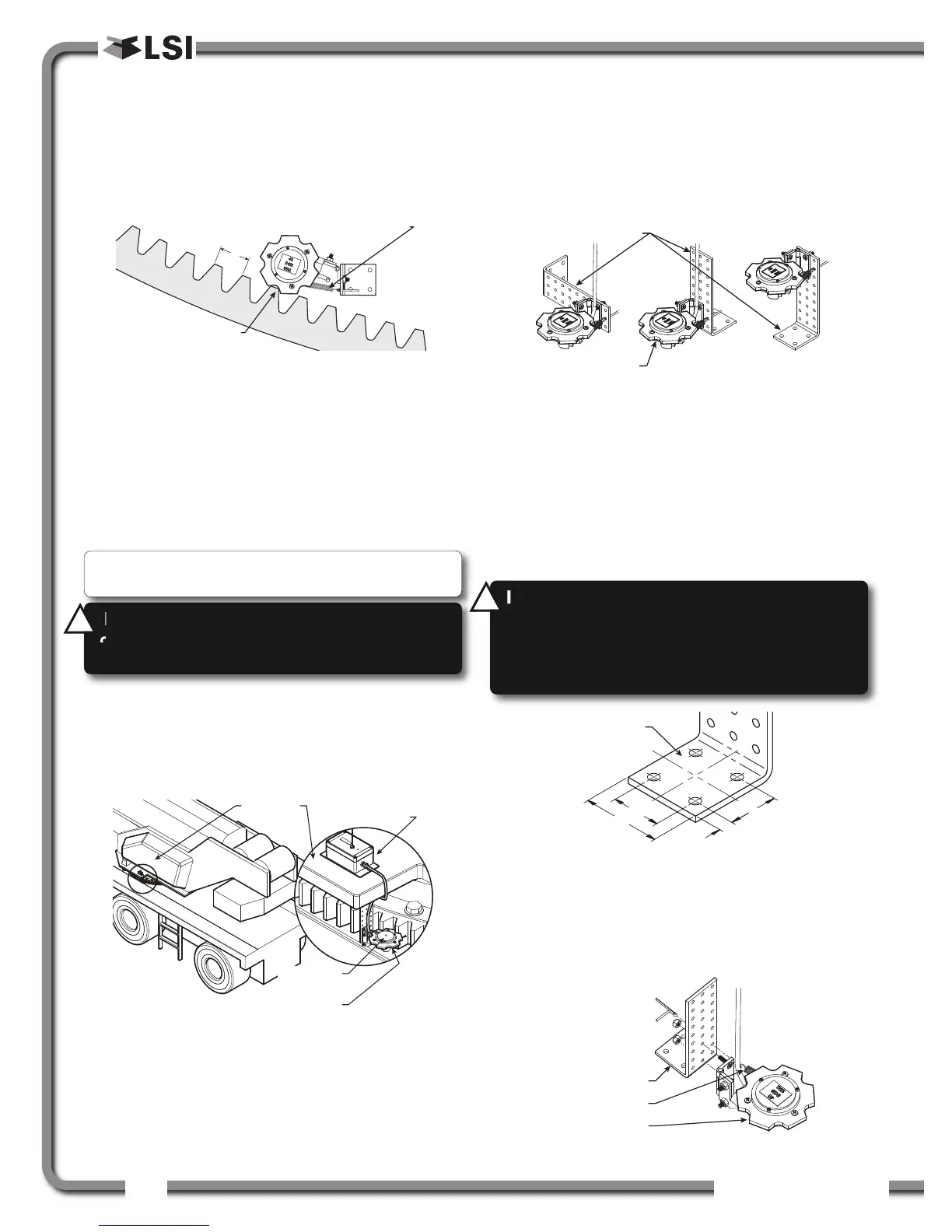

2.14a Encoder Gear Verification

Verify that the slew (swing) sensor was supplied with

the correct gear for your application;

a. Roll the encoder gear on the crane slew

gear; it should roll without skipping.

b. The distance between the leading edges (X)

of the slew gear teeth should correspond to

the gear model shipped with your order.

Example: P/N PA133-01 corresponds to a

slewgear with teeth leading edges 2 in. apart.

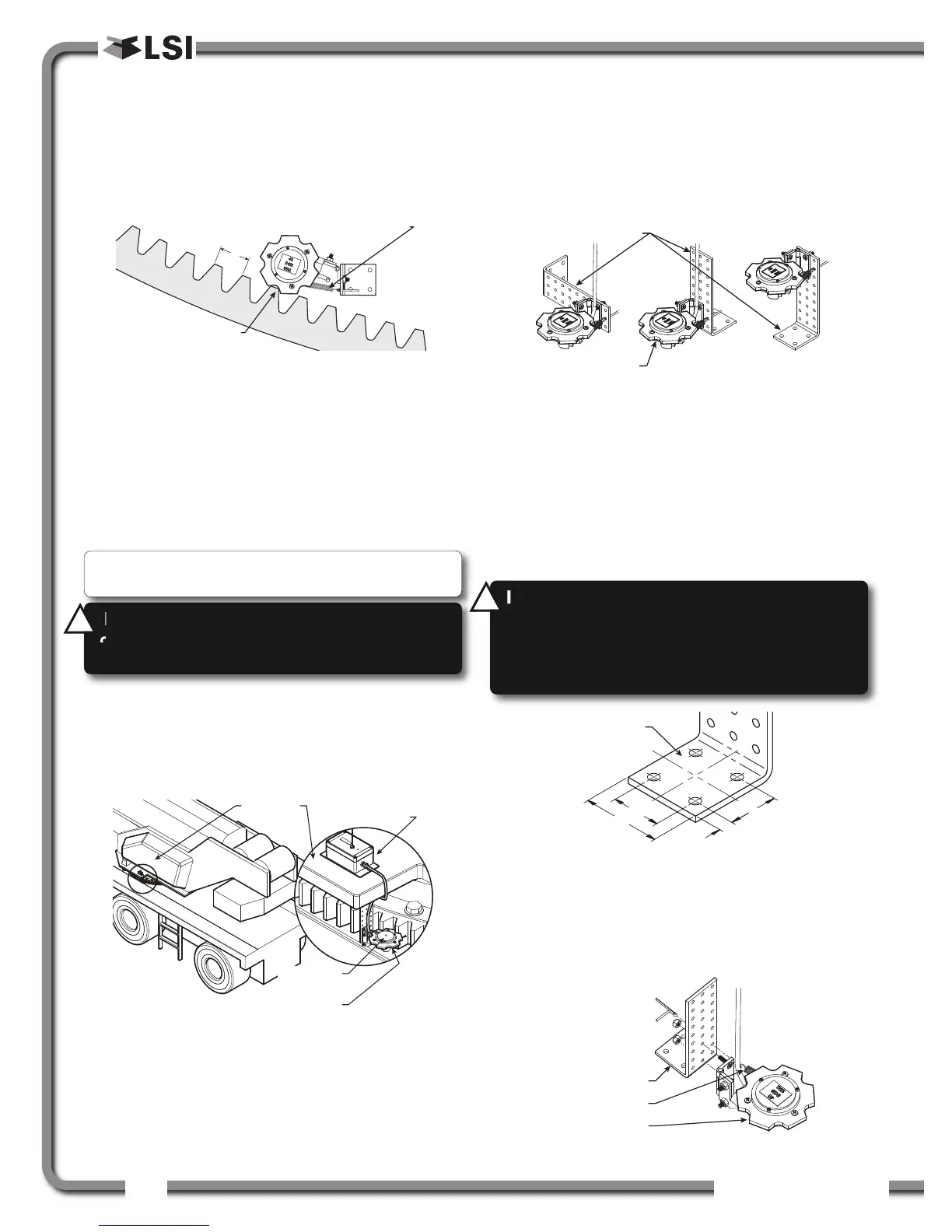

2.14b Slew Encoder Location

1. Install the slew encoder near the crane slew

gear where it will roll freely on the slew gear

when the crane slews.

2. Make sure that the slew encoder does not come

into contact with any other parts of the crane

through the full motion of the crane upper body.

2.14c Slew Encoder Orientation

The slew encoder bracket is designed so that the

encoder can be installed on either bottom, top or

side surfaces. If the surface on which the sensor is

to be installed is not at a square angle to the slew

gear, the mounting plate can be bent and/or cut.

2.14d Slew Encoder Installation

1. Find a rigid, level space near the slew gear to

install the slew encoder mounting bracket.

2. Weld the mounting bracket in place or install

with 1/4 in. screws. The screws can be installed

directly on the crane plate or a custom weld pad

can be built and welded on the crane.

3. Once the mounting bracket is installed, screw

on the encoder with the nuts and bolts provided.

Put tension on the spring by inserting the cotter

pin in the middle hole in front of the hinge.

Note: The slew sensor can be installed on either

internal or external tooth slew gears.

x

Encoder gear rolls

on the tooth edges

This spring needs to be in tension and keeps the

slew encoder gear in strong contact with the slew gear

Figure: Encoder gear verification.

Crane Upper

Body

Slew Sensor

Transmitter GS030

Slew Sensor

Encoder GS031

This side up in

wet locations

Figure: Slew encoder location. Typical installation.

Slew Sensor Encoder

Slew Encoder Bracket

Figure: Slew encoder bracket orientation.

WARNING!

Keep the slew encoder away from

any connecting metal structures when welding

mounting bracket to the boom. Proximity to

welding may cause permanent damage to the

slew encoder and render the system unsafe.

!

!

Figure: Mounting bracket footprint. Dimensions are in inches.

Slew Sensor Encoder

Slew Encoder Spring

Slew Encoder Bracket

Figure: Slew encoder installation. Typical installation.

WARNING!

Missing or damaged teeth on the

crane slew gear will prevent proper operation of

the slew sensor and render the system unsafe.

!

!

Loading...

Loading...