INSTALLATION

INSTALLATION

33

33

2.14e Slew Transmitter Location

The slew transmitter is connected to the slew

encoder with a 6 ft. cable but it can be installed

beside the transmitter if convenient; the cable can

be cut to the length required.

2.14f Slew Transmitter Installation

1. Screw the slew transmitter to a flat surface with

1/4 in. screws.

2. If needed, weld pads can be used to facilitate

transmitter installation.

3. Tie wraps can be used to secure the cable

between the encoder and transmitter.

2.14g Cable Length Adjustment

If the cable between the encoder and transmitter is

too long, it can be cut to the desired length;

1. Remove the cover from the transmitter using

either a flat or a Phillips № 2 screwdriver.

2. Using a small flat screwdriver, loosen the 6 screws

of the terminal block and remove the wires from it.

Lay down the transmitter cover on a clean surface.

3. Loosen the cable gland with a 3/4 in. wrench and

pull the cable from the inside of the transmitter box

until you reach the desired length. Tighten the gland

back with the wrench. Do not to overtighten.

4. Cut the cable excess, leaving about 4 in. in the

transmitter box. Remove the sheath to about 2 in.,

remove the shield and remove the individual

sheaths on the 6 wires to about 1/4 in. Connect

the 6 wires in the terminal block respecting the

color codes and tighten the terminal block screws.

5. Replace the transmitter cover and screw it in place.

6. Test the sensor for proper function: start-up

the display and move the encoder wheel.

2.15

2.15

Slew sensor calibration

Slew sensor calibration

The slew sensor need to be calibrated on the crane

where it is installed on before utilisation.

1. Go to Menu 4B1A), select the slew sensor and

press Enter. Press Next to start the slew

calibration wizard.

2. Menu 1/5) CRANE GEAR TEETH: Enter the teeth

count of crane’s slew gear.

3. Menu 2/5) SENSOR GEAR TEETH: Enter the teeth

count of the gear of the slew sensor installed.

4. Menu 3/5) ADJUST/CONFIRM SLEW VALUE: Enter the

current position of the slew (swing).

5. Menu 4/5) REVERSED ROTATION: Depending on how

the slew sensor is installed, the rotation direction

may be reversed. The slew value should go up

when you swing to right (clockwise).

6. Menu 5/5) PRESS ENTER TO SAVE CALIB IN SENSOR:

the settings will be saved in the sensor.

Note: The tension applied by the slew encoder

spring is required to keep the encoder gear in

contact with the slew gear.

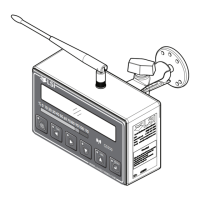

IMPORTANT!

To ensure reliable radio

communication between the slew sensor

and the GS550 display, the following

conditions must be respected:

• The antenna of the slew transmitter should

not be in contact with metal.

•The antenna should point to the left or to the

right of the boom; it should not point directly

to, or away from, the GS550 display.

•The antenna should have a clear line of sight

to the GS550 display; in most cases this

means mounting the transmitter outside of

the crane structure on the same side of the

boom as the operator's cab.

!

!

IMPORTANT!

Do not weld in proximity to

LSI

LSI sensor/transmitters.

!

!

IMPORTANT!

The transmitter must be

installed such that it does not interfere with

the crane through all normal movements. It may

be installed at any angle as long as the cover can

be removed when required to change the battery.

!

!

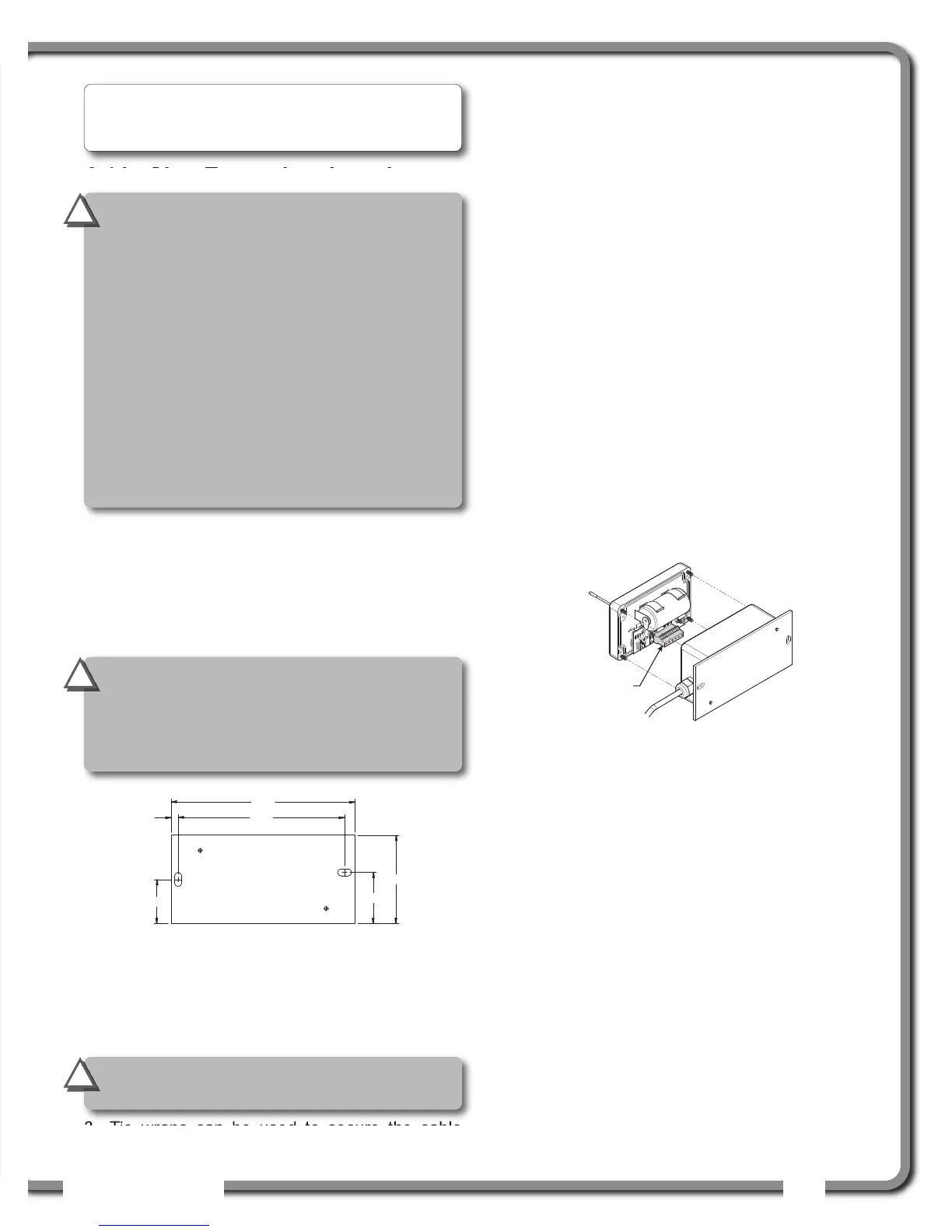

6,50

3,13

,25

5,88

1,56

1,81

Gland

side

Figure: Slew transmitter. Dimensions are in inches. Not to scale.

Figure: Cable length adjustment.

Loading...

Loading...