OPERATION

OPERATION

39

39

Information Menu Alerts (Continued)

Alert:

Description:

Voltage is not detected on the lockout wire when safe**.

With the standard relay configuration voltage should be

present on a lockout wire in safe condition.

• Verify the wire is not shorted to ground.

•Verify the wire is not connected directly to the

valve coils; a relay should be installed between

the wire and the valve coils. Refer to the Power

Supply and Lockout Connection sub section of

this manual.

Alert:

Description:

One or more primary conditions of the chart selected for

the hoist is not met (example: telescopic boom length).

•Verify the conditions of the selected rated capacity

chart.

Alert:

Description:

The boom or jib angle is above the maximum angle

permitted by the selected chart. (For charts determined

by radius only, this message will occur when the radius

is less than the minimum radius permitted by the chart).

•Verify the boom and jib angles permitted by the

rated capacity chart selected.

Alert:

Description:

The boom or jib angle is under the minimum angle

permitted by the selected chart. (For charts determined by

radius only, this message will occur when the radius is

greater than the maximum radius permitted by the chart).

•Verify the boom and jib angles permitted by the

rated capacity chart selected.

**If the lockout relay is inverted this alert will occur

when voltage is not detected on the wire in alarm.

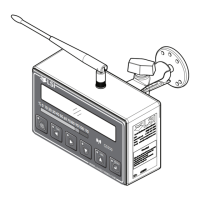

3.3c Limit

Set Hoist Limits

Press Limit and then Enter to access the Sensor Limits

menu. The Sensor Limits menu displays the limits for

each sensor in the sensor list on successive pages.

Use Next to scroll from one limit to the next.

Use Up and Down to adjust a limit.

When using the GS550 as a load indicator without

programmed crane specific rated capacity charts the

load limit is typically set to the lesser of the rope limit,

the hoist limit, and the maximum allowed capacity

as determined from the capacity charts.

When using the GS550 as a rated capacity indicator

with programmed crane specific rated capacity

charts the load limit is typically set to the lesser of

the rope limit and the hoist limit.

Set Work Area Limits

The Work Area Limits menu is only available if a

slew, radius or tip height is configured in the system.

Press Limit, Next and then Enter to access the

Work Area Limits menu. To program fixes and

dynamics limits, refer to section 3.9 Work Area

Management Programmation.

3.4

3.4

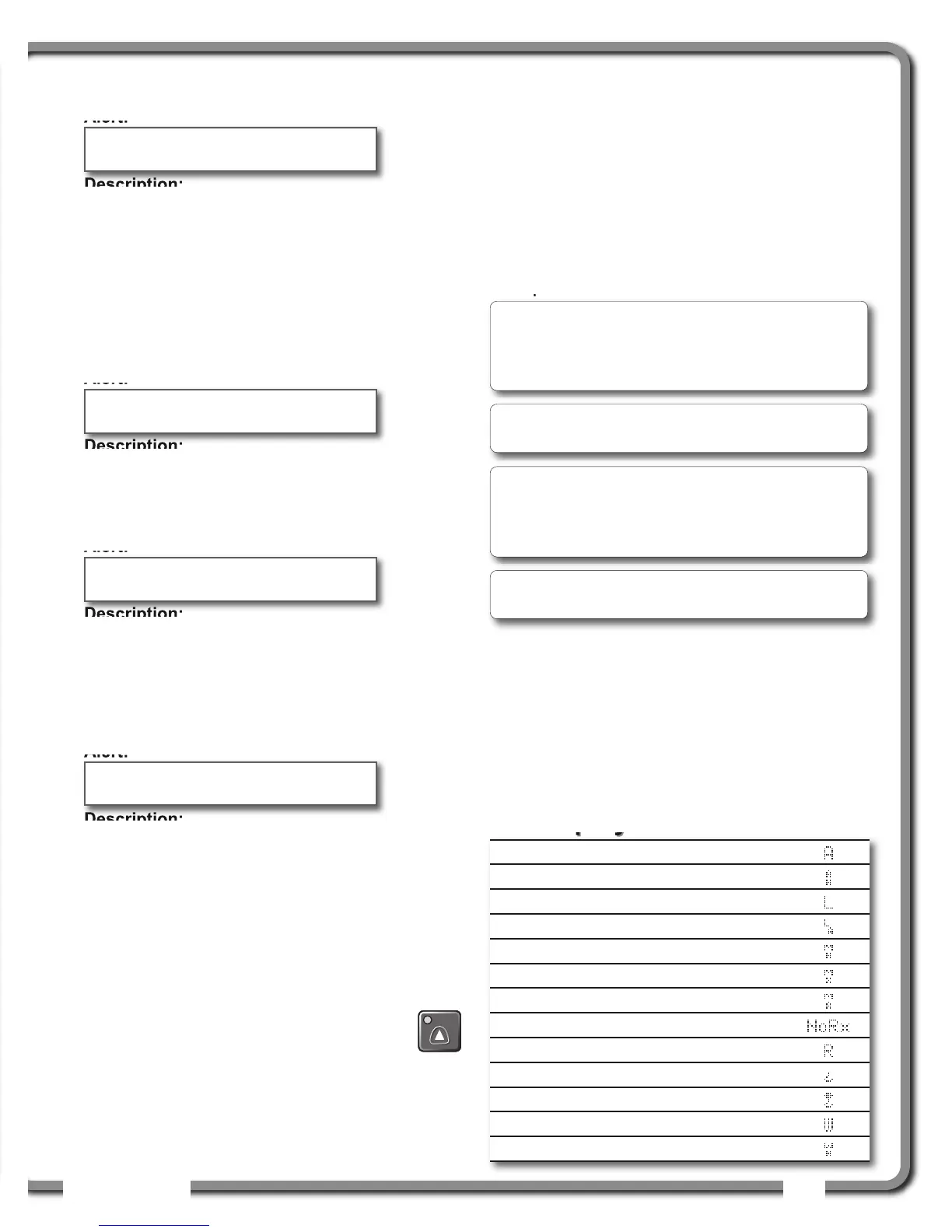

Display abbreviations

Display abbreviations

Verify white wire

(shorted to ground)

Main

Out of chart

Main angle

above chart maximum

Main angle

below chart minimum

Angle

Auxiliary hoist

Length

Luffing angle

Main hoist

Maximum

Maximum or minimum angle

Communication not established

Radius

Tare (net weight)

Gross weight

Wind speed

Whip hoist

Note: Press Up and Down simultaneously to

return a limit to the factory default setting. The

factory default maximum limit for load sensors is

10 000 lb per part of line.

Note: When the weight units are tons the minimum

load limit increment is 0.1 ton per part of line.

Note: The limits set in the limit menu are different

than those set in the work area limits; the limits set

in Limit menu will stay active even if no work area

has been defined.

Note: to desactivate the permanent slew limits in the

limit menu, the right and left limit should be set to 0.

Loading...

Loading...