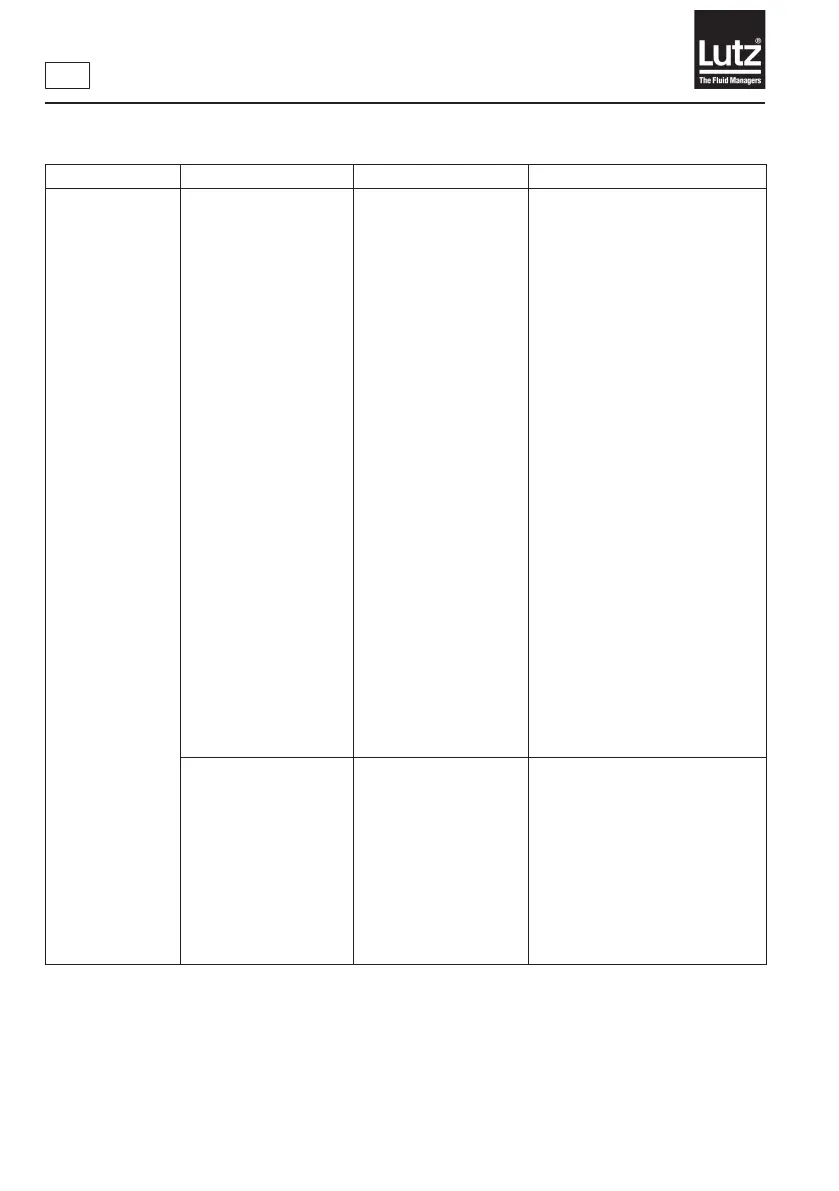

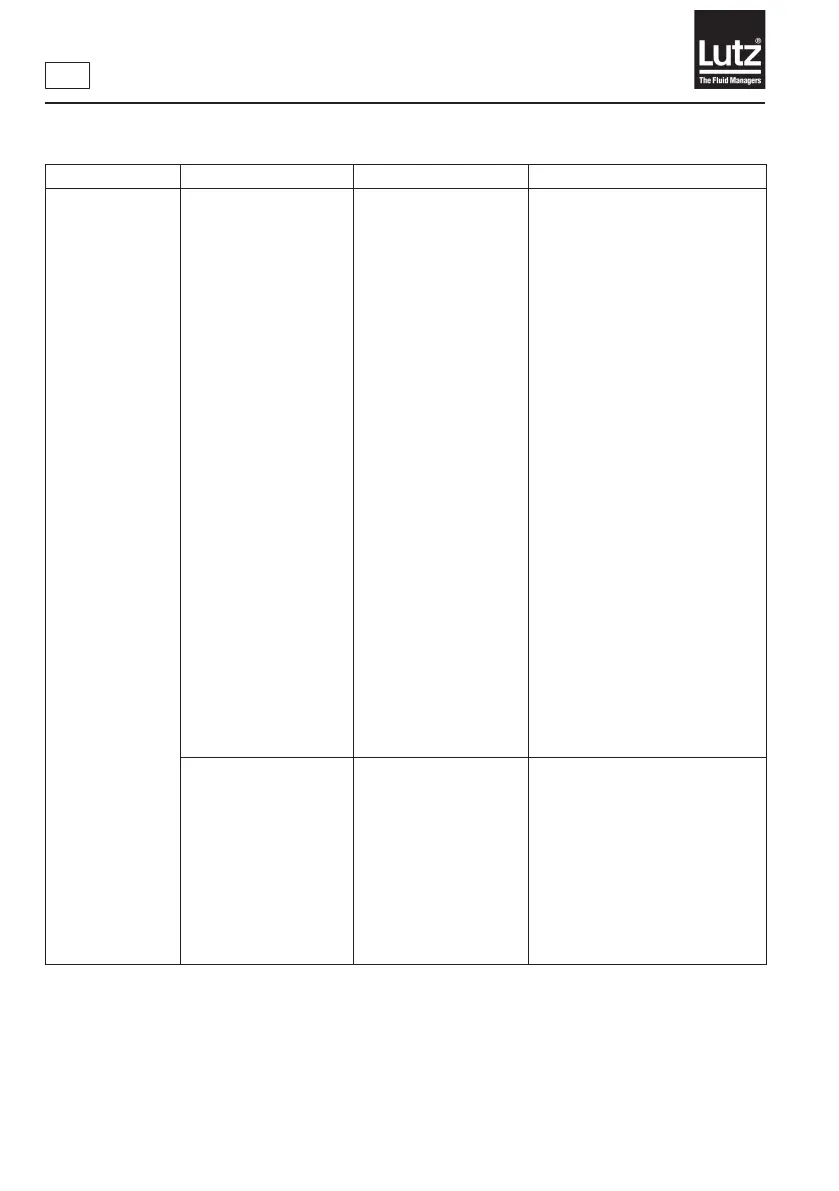

2.2 Other faults

Operating mode Fault Cause Remedy

General No liquid registered • Air in the piping

system/dry running

• Prevent air pockets in

connecting lines, use a solid

hose system

• Pump is not

operating

• Check pump

• Line strainer blocked • Clean strainer

• Time required to

lltheconnecting

lines exceeds the set

monitoring time

• Increase monitoring time

• Hose line kinked • Check hose line

• Solenoid valve

damaged

• Check solenoid valve

• The connection

between the modules

is interrupted

• Check bus line

• Foreign matter in the

basicowmeter

• Cleanbasicowmeter

• Basicowmeter

damaged

• Checkbasicowmeter

• Fuse in relay module

defective

• Check fuses

• Magnet or sensor

inbasicowmeter

damaged

• Checkbasicowmeter

Measured quantity

dierssignicantly

from the actual

quantity

• Correction factor does

not match operating

conditions

• Calibrateowmeter

• Fluid is too viscous • Calibrateowmeter

• Leaks in hose system • Install check valve if necessary

• Bleed air from system

• Radio interference on

the data line

• Route the data line separate

from other lines

72

0698-651 Operating unit - 04/2021

en

Loading...

Loading...