Inlet and Exhaust Valve Cones

Inspection / Disassembly and reassembly

A5.05. 01.07.01.01

7500, 15000

M20

en / 29.05.2000 IB021215 1/2

01

Ĺ

See also: 01.02.01.nn, 01.05.01.nn, 01.06.01.nn, 01.08.01.nn

Spare parts list: B1.05.01.2.2107

Time requirement: 1 Pers./ 0,50 h

Personnel qualification: skilled engine hand

---------------------------------------------------------------------------------------------------------------------

Operating medium: Heavy fuel

Inspection:

of inlet and exhaust valves of one cylinder after 7,500 h

Check contact reflections of the valves and coating.

Maintenance:

of all inlet and exhaust valves after 15,000 h

Tools:

Valve spring compressor W1 2.9222-A

Note:

The overhaul intervals of the valves depend on the fuel grade used, the operating

conditions of the plant and the quality of the reconditioned valves and seats. They are

therefore different for each plant.

For this reason, the operator must fix the maintenance intervals according to the condition

of valves inspected. With any removal of valves, check seat geometry and recut if

necessary (01.08.01.nn, 01.08.02.nn.).

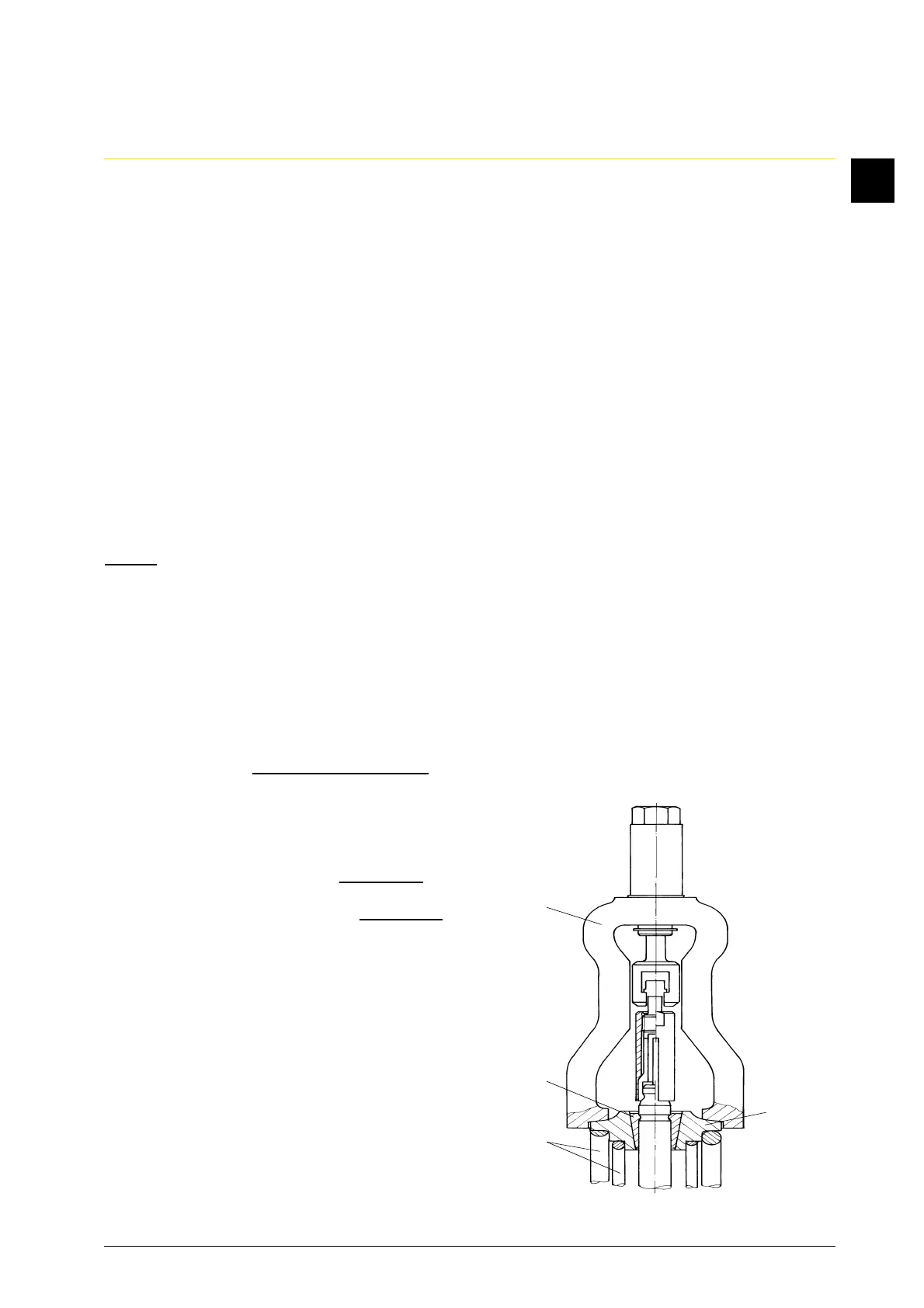

Sequence of operations: (Fig. 1)

1. Disassembly

1.1 Remove cylinder head (01.06.01.nn).

1.2 Remove the valve rocker (01.02.01.nn)

and lift off valve bridge.

1.3 Place the valve spring compressor (W1)

onto the spring plate (2).

1.4 Compress the valve springs (3) and

remove the clamping cone halves (4).

Expand valve springs (3) carefully.

ĭ Safety note:

Spring tension

2

3

4

W1

Fig. 1

Loading...

Loading...